A kind of preparation method of copolyester polyurethane

A copolyester and polyurethane technology, applied in the field of polymer synthesis, can solve the problems of difficult separation and purification, high production cost, time-consuming and labor-intensive, etc., and achieve the effects of adjusting the main chain structure, low cost and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a kind of preparation method of copolyester type polyurethane, and this preparation method comprises following two-step reaction:

[0044] Reaction 1: Under the synergistic catalysis of the non-metallic two-component catalyst, the anionic ring-opening polymerization reaction of the acid anhydride monomer and the epoxy monomer is carried out to obtain a copolyester alternating copolymer;

[0045] Reaction 2: Addition polymerization of the copolyester alternating copolymer and diisocyanate to obtain copolyester polyurethane;

[0046] Wherein, the non-metallic two-component catalyst includes two components of a thiourea compound and an organic base compound.

[0047] The present invention uses a dihydroxy compound as a chain transfer agent, adopts a non-metallic composite catalytic system composed of a thiourea compound and an organic base compound to synergistically catalyze the anionic ring-opening and alternating copolymerization of an anhydride m...

Embodiment 1

[0090] A kind of preparation method of copolyester type polyurethane comprises the serial reaction of synthesizing copolyester 1 and synthesizing poly[copolyester 1-isophorone diisocyanate], specifically comprises the following steps:

[0091] (1) In an anhydrous and oxygen-free environment, the thiourea compound 1,3-diisopropyl-2-thiourea and the organic base compound 1,8-diazabicyclo[5.4.0]undecyl- Add 0.0137g and 12.8μL of 5-ene into a 10mL reactor according to the molar ratio of 1:1, and then take 3mL and 1.2700g of the monomer propylene oxide and phthalic anhydride according to the molar ratio of 500:100 Add it and mix evenly to obtain raw material mixing system A.

[0092] (2) Add 15.4 μL of water to the raw material mixing system A described in step (1) as a chain transfer agent, the molar ratio of water to 1,3-diisopropyl-2-thiourea is 10:1, mix well and Raw material mixing system B was obtained.

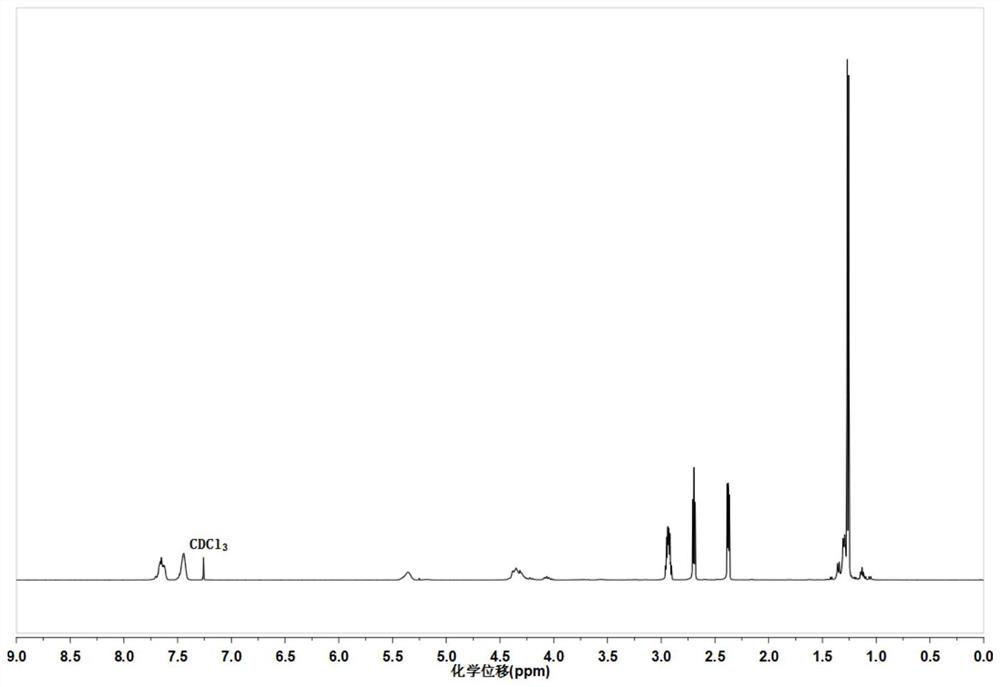

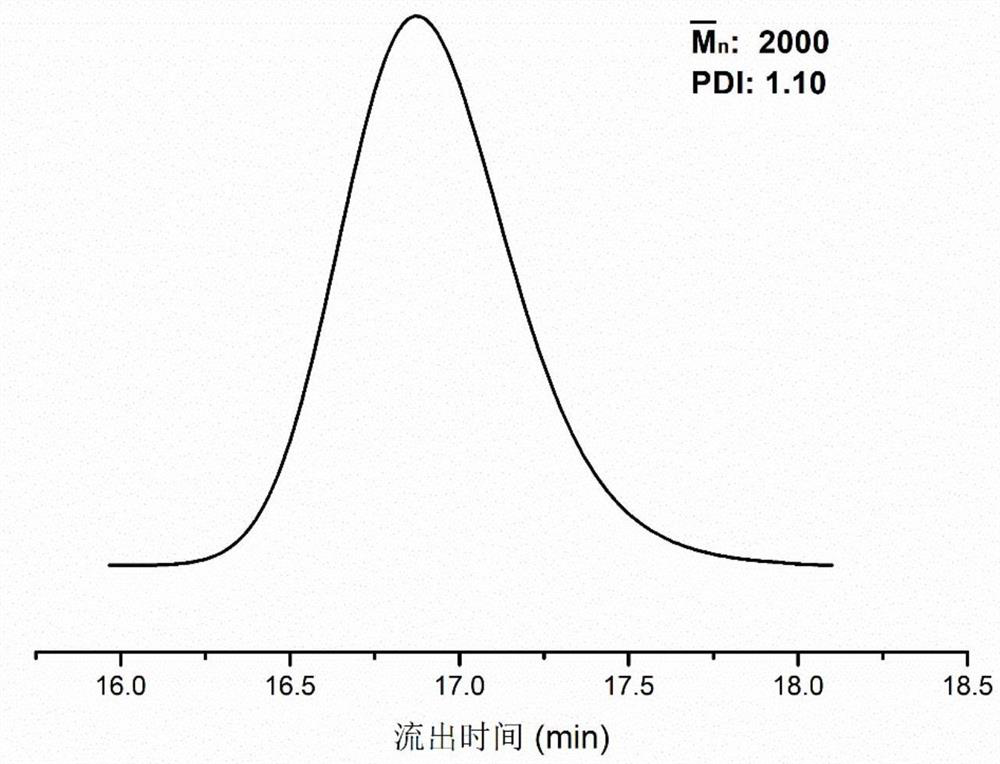

[0093] (3) The raw material mixed system B obtained in step (2) was s...

Embodiment 2

[0105] A kind of preparation method of copolyester polyurethane comprises the series reaction of synthesizing copolyester 2 and synthesizing poly[copolyester 2-isophorone diisocyanate], specifically comprises the following steps:

[0106] (1) In an anhydrous and oxygen-free environment, the thiourea compound 1,3-diisopropyl-2-thiourea and the organic base compound 1,8-diazabicyclo[5.4.0]undecyl- Add 0.0069g and 32.0μL of 5-ene into a 10mL reactor according to the molar ratio of 1:5, and then take 3mL and 0.6350g of the monomer propylene oxide and phthalic anhydride according to the molar ratio of 1000:100 Add it and mix evenly to obtain raw material mixing system A.

[0107] (2) Add 0.0592g tere-xylylenedimethanol to the raw material mixing system A described in step (1) as a chain transfer agent, and the molar ratio of tere-xylylenedimethanol to 1,3-diisopropyl-2-thiourea is 10 : 1, mix uniformly to obtain raw material mixing system B.

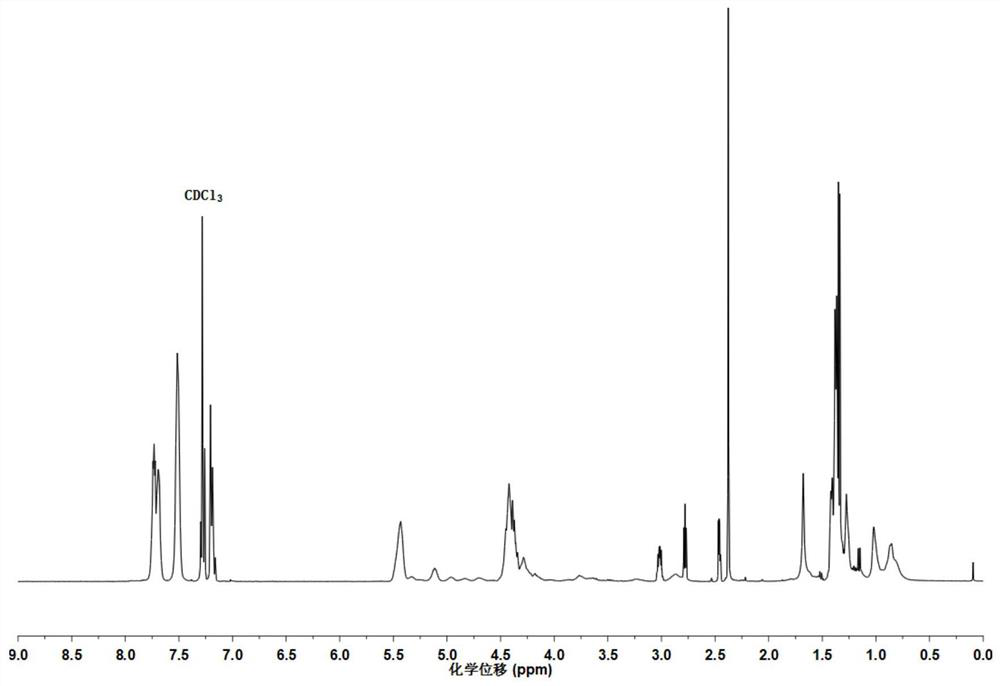

[0108] (3) The raw material mixed sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com