Grafted polypheylene ether resin and preparation method thereof

A technology of polyphenylene ether resin and mixed resin, applied in the field of polyphenylene ether resin, can solve the problems of poor mechanical properties and easy cross-linking of polyphenylene ether resin, achieve improved tensile strength, uniform concentration distribution, and avoid monomer uniformity. The effect of poly and polyphenylene ether crosslinking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

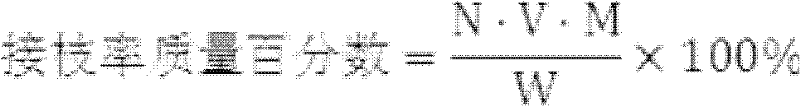

Method used

Image

Examples

Embodiment 1

[0029] (1) Be the poly-2,6-dimethyl-1,4-phenylene ether that intrinsic viscosity is 38ml / g, under air atmosphere, carry out pre-irradiation with β ray on electron accelerator device, pre-irradiation dose is 10kGy to obtain pre-irradiated poly 2,6-dimethyl-1,4-phenylene ether;

[0030] (2) 85 parts by mass of the poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether 15 parts of resin mass parts are added in the high-speed mixer together, mix, obtain mixed resin;

[0031] (3) The mixed resin obtained in step (2) is added in the main hopper of the Haake reaction type twin-screw extruder, and the mass parts are 10 parts of acrylic acid and 2 parts of p-benzoquinone through the Haake reaction type twin-screw extruder The liquid feeding port of machine is injected, carries out reactive extruding grafting, and the screw rod diameter of described Haake reactive type twin-screw extruder is 24mm, and length-to-diameter ratio is 40, a...

Embodiment 2

[0039] (1) The poly 2,6-dimethyl-1,4-phenylene ether resin that intrinsic viscosity is 42ml / g, under air atmosphere, carries out pre-irradiation with β ray on electron accelerator device, pre-irradiation dose 40kGy to obtain pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether;

[0040] (2) 65 parts by mass of the poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether 35 parts of resin mass parts are added in the high-speed mixer together, mix, obtain mixed resin;

[0041](3) Add the mixed resin obtained in step (2) into the main hopper of the SHJ-30 reactive twin-screw extruder, and the temperature of each section from the feeding port to the die is 200, 220, 240, 260, 270, 280, 280, 285, 285, 290, 280°C, speed 75 rpm, inject 0.5 parts by mass of acrylic acid and 0.05 parts of triphenyl phosphate through the liquid feeding port of SHJ-30 reactive twin-screw extruder , carry out reactive extrusion grafting, and the reaction...

Embodiment 3

[0046] (1) Poly 2,6-dimethyl-1,4-phenylene ether resin with an intrinsic viscosity of 40ml / g is pre-irradiated with β-rays on an electron accelerator device under an air atmosphere, and the pre-irradiation The dose is 30kGy to obtain pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether;

[0047] (2) 75 parts by mass of the pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether resin 25 parts by mass are added together in a high-speed mixer and mixed to obtain a mixed resin;

[0048] (3) Add the mixed resin obtained in step (2) into the main hopper of the SHJ-30 reactive twin-screw extruder, and the temperature of each section from the feeding port to the die is 200, 230, 250, 270, 270, 280, 285, 285, 285, 290, 280°C, speed 120 rev / min, put 5 parts by mass of acrylic acid and 1 part by mass of triphenyl phosphate through the liquid of SHJ-30 reactive twin-screw extruder The feeding port is injected to carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com