Alkali-soluble resin, photosensitive resin composition, and use thereof

A technology of alkali-soluble resin and solvent, which is applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problems of difficult pattern formation and poor developability, and achieve the effect of inhibiting crosslinking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~3

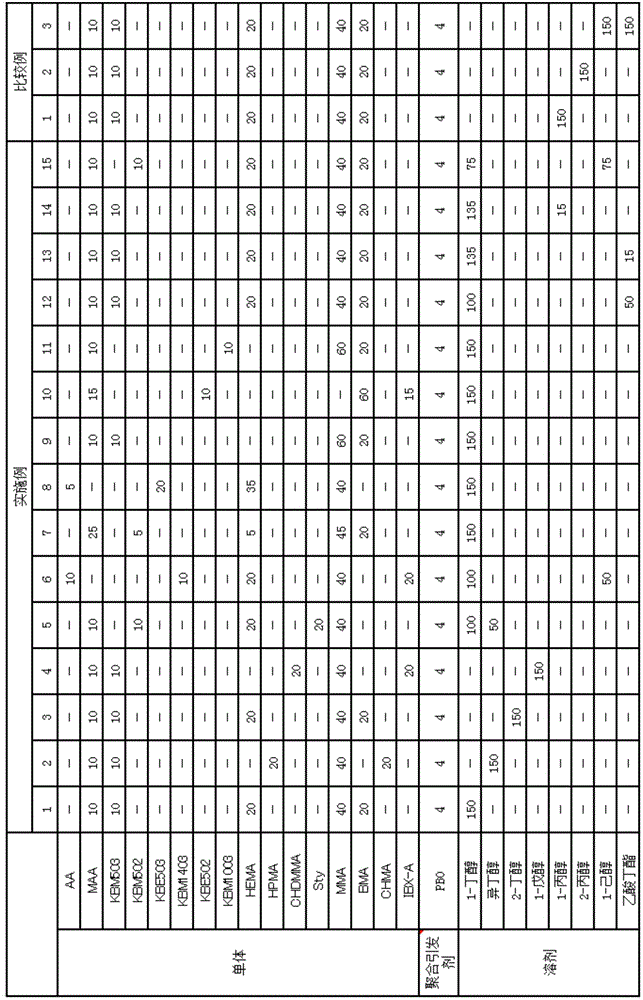

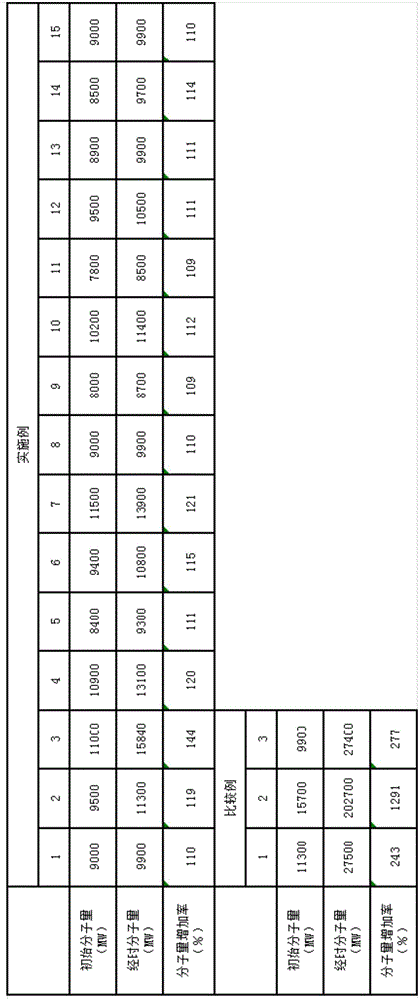

[0104] (Examples 1-15 and Comparative Examples 1-3, preparation of alkali-soluble resin)

[0105] The solvents shown in Table 1 were charged into a flask equipped with a stirrer, a thermometer, a condenser, and a nitrogen gas introduction tube, and the temperature was raised to an appropriate temperature under a nitrogen atmosphere. In addition, the monomers and polymerization initiators shown in Table 1 were mixed to prepare a liquid mixture, and this liquid mixture was dropped into the solvent over 4 hours. Thereafter, it was reacted for 3 hours to prepare an alkali-soluble resin. In addition, the compounding quantity in Table 1 shows a mass part.

[0106] 【Table 1】

[0107]

[0108] The simplified symbols in Table 1 are expressed as follows.

[0109] AA: Acrylic

[0110] MAA: methacrylic acid

[0111] KBM503: γ-Methacryloxypropyltrimethoxysilane

[0112] KBM502: γ-Methacryloxypropylmethyldimethoxysilane

[0113] KBE503: γ-Methacryloxypropyltriethoxysilane

[0114...

Embodiment 16~33 and comparative example 4~6

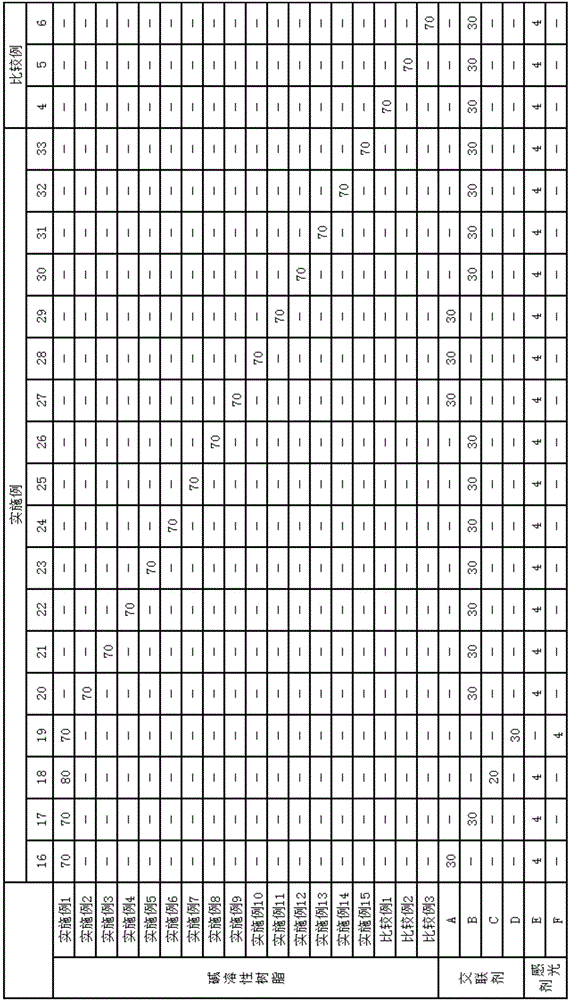

[0135] (Examples 16-33 and Comparative Examples 4-6, preparation and evaluation of photosensitive resin composition)

[0136] The alkali-soluble resins of Examples 1 to 15 and Comparative Examples 1 to 3 (alkali-soluble resins prepared at the initial stage and left to stand at 40° C. for 2 weeks) and the crosslinking agents shown in Table 3 and The photosensitive agents are mixed to prepare a photosensitive resin composition. In addition, the compounding quantity in Table 3 represents a mass part.

[0137] 【table 3】

[0138]

[0139] The simplified notation in Table 3 is as follows.

[0140] Crosslinker A: 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate

[0141] Crosslinking agent B: Etherified methylol melamine [NIKALAC MW30M manufactured by Sanwa Chemical Co., Ltd.]

[0142] Crosslinking agent C: silica-doped epoxy resin [Compoceran E102B manufactured by Arakawa Chemical Industry Co., Ltd.]

[0143] Crosslinker D: Trimethylolpropane trimethacrylate

[0144...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com