A kind of resin for dripping film and its preparation method and application

A dripping film and resin technology is applied in the field of resin for dripping film and its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

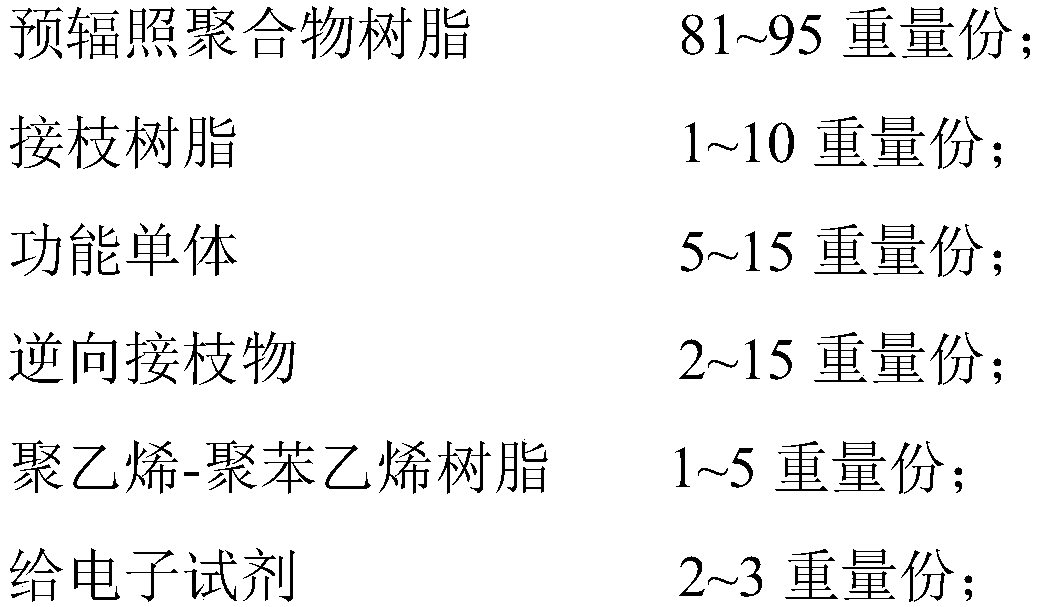

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of resin for dripping film, the steps are as follows:

[0060] Step 1. Preparation of pre-irradiated polymer resin

[0061] use 60 Co as the radiation source, under the air atmosphere, the polymer resin is pre-irradiated with γ-rays, and the pre-irradiation dose ranges from 10 to 60 kGy to obtain the pre-irradiated polymer resin;

[0062] Or use an electron accelerator as the irradiation source, and pre-irradiate the polymer resin with β-rays in an air atmosphere, and the pre-irradiation dose ranges from 10 to 60 kGy to obtain the pre-irradiated polymer resin;

[0063] Wherein, polymer resin is the mixing of one or more of low-density polyethylene, linear low-density polyethylene, ethylene-vinyl acetate copolymer in any proportion, when adopting multiple mixing in any proportion, in subsequent steps When using pre-irradiated polymer resins, the same pre-irradiated polymer resins can be used in different steps, o...

Embodiment 1

[0094] Step 1. Under normal temperature, normal pressure and air conditions, pre-irradiate the ethylene-1-butene copolymer resin with a butene mass percentage content of 6.7% with β-rays of an electron accelerator, and the dose of the pre-irradiation treatment is 10kGy , to obtain pre-irradiated ethylene-1-butene copolymer resin;

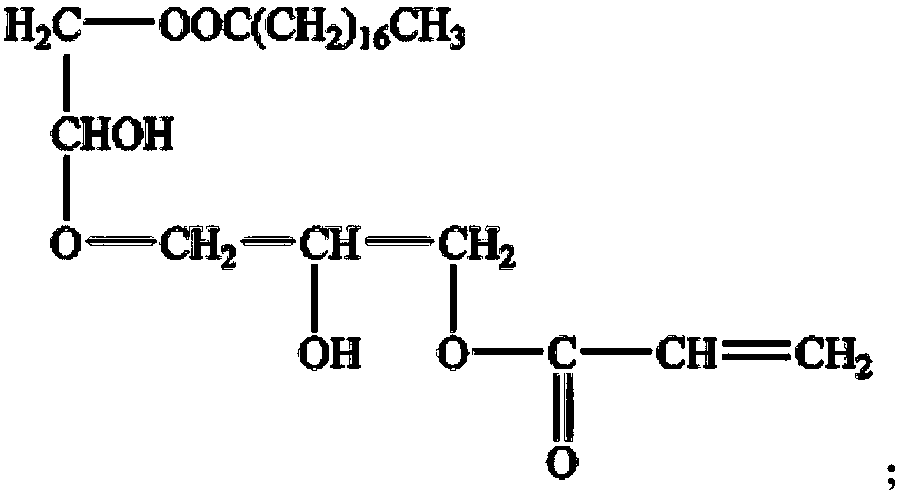

[0095] Step 2. Add the pre-irradiated ethylene-1-butene copolymer resin and diglyceryl monostearic acid monoacrylic acid diester obtained in step 1 into a high-speed mixer at a mass ratio of 100:3, and mix them for 3 minutes in a high-speed mixer , added to the SHJ30 reactive twin-screw extruder system, the aspect ratio is 44, the temperature from the feed to the die is 160, 170, 180, 190, 195, 195, 195, 190 ° C, extrusion, pulling Strips, cooling, granulation to obtain grafted resin;

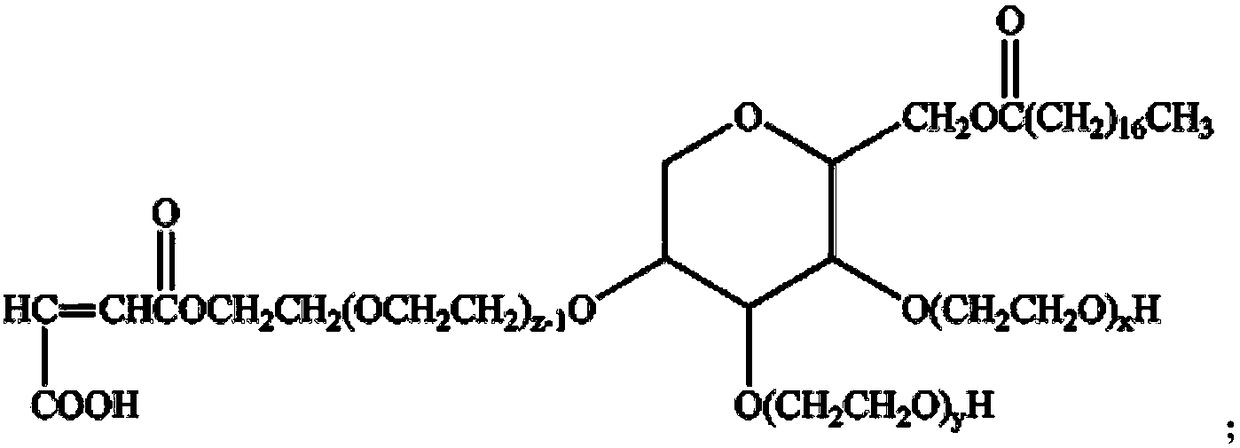

[0096] Step 3, mix Tween60, maleic anhydride, p-toluenesulfonic acid, xylene and p-hydroxyanisole in a molar ratio of 0.19:0.19:10 -3 :0.7:10 -3 Add it into the r...

Embodiment 2

[0103] Step 1. Under normal temperature, normal pressure and air conditions, use ethylene-1-hexene copolymer resin with a hexene mass percentage content of 8% 60 The gamma ray pre-irradiation treatment of Co, the dose of pre-irradiation treatment is 60kGy, obtains pre-irradiation ethylene-1-hexene copolymer resin;

[0104] Step 2. Add the pre-irradiated ethylene-1-hexene copolymer resin weight parts obtained in step 1 and diglyceryl monostearic acid monoacrylic acid diester into a high-speed mixer at a mass ratio of 100:5, and mix through a high-speed mixer After 3 minutes, add it to the SHJ30 reactive twin-screw extruder system, the aspect ratio is 44, the temperature from the feed to the die is 160, 175, 185, 190, 190, 195, 195, 190 ° C, extruded , stretching, cooling, and granulating to obtain grafted resin;

[0105] Step 3, mix Tween60, maleic anhydride, p-toluenesulfonic acid, toluene and p-hydroxyanisole in a molar ratio of 0.25:0.25:4×10 -3 :1.1:4×10 -3 Add it into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com