Method for preventing packing in rubber blend from migration

A technology of rubber blends and rubber mixtures, which is applied in the field of production technology to improve the performance of rubber mixtures, and can solve problems such as unfavorable performance of the airtight layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Polar, weakly polar and non-polar rubbers only aim at the relative strength of polarity between different component rubbers in a certain rubber blend. For BIIR2222 and STR20, STR20 is a non-polar rubber, and BIIR2222 For weakly polar rubber.

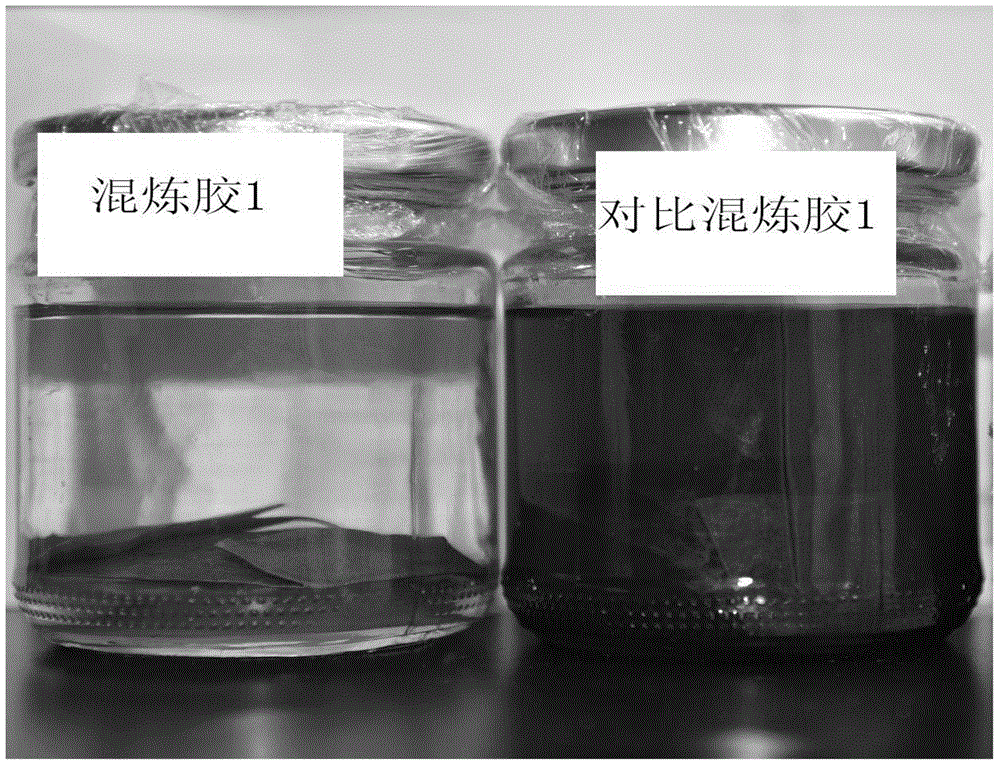

[0074] Add 100 parts of BIIR2222 and 60 parts of N660 into the internal mixer for one-stage mixing, the mixing temperature is 160°C, and the mixing time is 5 minutes; add 100 parts of STR20 and 60 parts of N660 into the internal mixer for one-stage mixing, mixing The mixing temperature is 160°C, the mixing time is 5 minutes, the speed of the internal mixer is 60 rpm, the rubber is discharged after mixing evenly, and after parking for 4 hours; 120 parts of BIIR2222 masterbatch, 40 parts of STR20 masterbatch, 18 parts Add calcium carbonate, 0.8 parts of stearic acid, 6 parts of naphthenic oil, 12 parts of hydrocarbon resin mixture, 4 parts of C5 petroleum resin, and 2 parts of octyl phenolic tackifying resin into the internal mixer ...

Embodiment 2

[0100] Polar, weakly polar and non-polar rubbers only aim at the relative strength of polarity between different component rubbers in a certain rubber blend. For BR9000 and SBR1500, BR9000 is a non-polar rubber, and SBR1500 For weakly polar rubber.

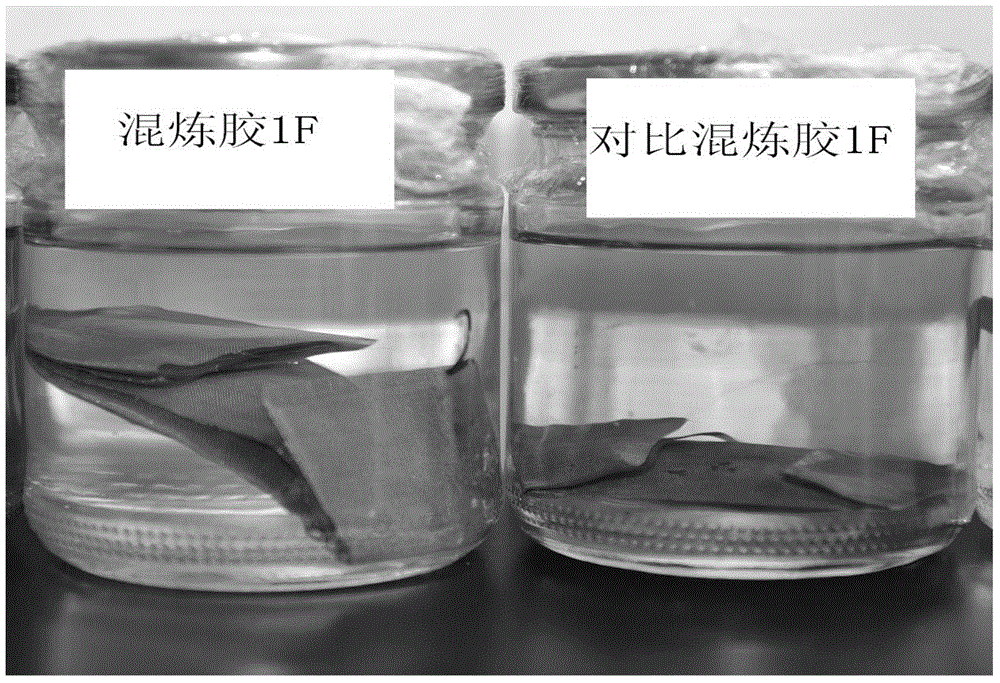

[0101] Add 100 parts of BR9000, 60 parts of N339 carbon black, and 3 parts of radiation sensitizer pentaerythritol triacrylate into the internal mixer for a period of mixing. The mixing temperature is 160 ° C, the mixing time is 5 minutes, and the speed of the internal mixer is 60 rpm, mix evenly and discharge glue; add 100 parts of SBR1500, 60 parts of N339 carbon black, and 3 parts of radiation sensitizer pentaerythritol triacrylate into the internal mixer for a stage of mixing, the mixing temperature is 160 ° C, The mixing time is 5 minutes; the speed of the internal mixer is 60 rpm, and the rubber is discharged after mixing evenly. After parking for 4 hours, 32 parts of BR9000 masterbatch, 128 parts of SBR1500 masterbatch, 3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com