Bifunctional interface lithium ion battery nickel-rich single crystal positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as unsuitable for large-scale promotion, difficult surface modification process, and large loss of material capacity, so as to maintain the integrity of particle structure Sex, reduce adverse side effects, good recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

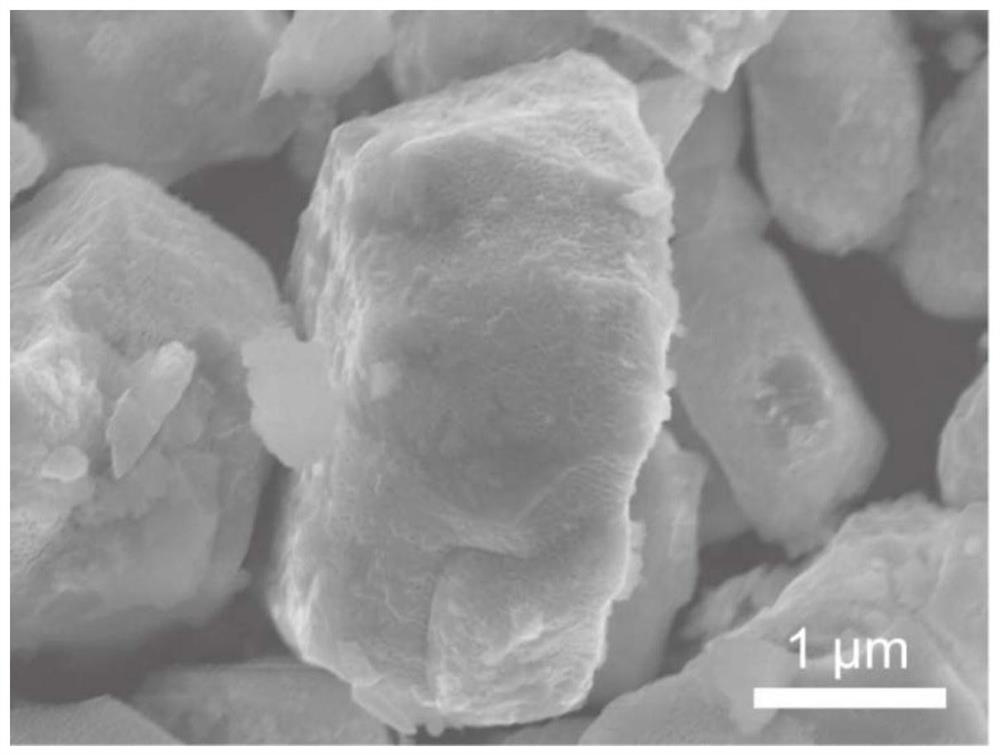

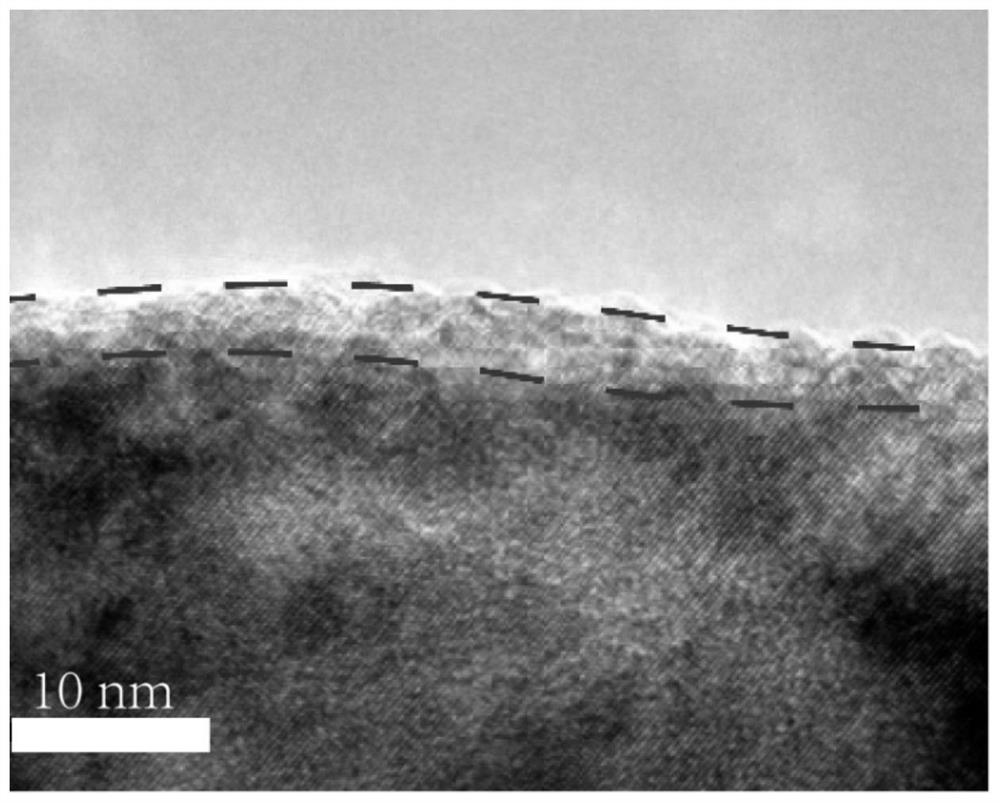

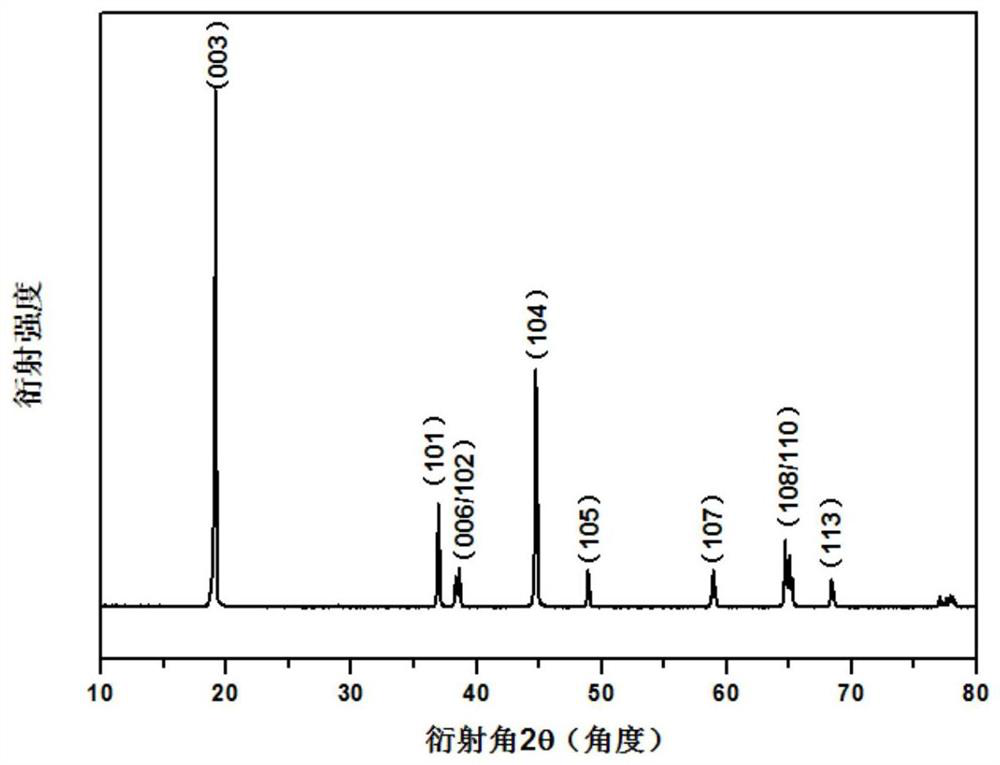

[0056] (1) 0.408g of Al(NO 3 ) 3 9H 2 O and 0.1436g (NH 4 ) 2 HPO 4 Dissolve slowly in 5g of water and stir until white AlPO is produced 4 precipitation.

[0057] (2) Continue to add 0.0144g (NH 4 ) 2 HPO 4 and 25g of cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Into the above solution, magnetically stirred at room temperature for 5 min.

[0058] (3) Take off the water heating oven transferred to 120°C, dry for 6 hours, remove the solvent, crush it with a mortar, put it in a tube furnace at 650°C in an oxygen atmosphere, and calcinate for 5 hours to obtain the bifunctional interface modified Nickel-rich single crystal cathode material.

Embodiment 2

[0060] (1) 0.408g of Al(NO 3 ) 3 9H 2 O and 0.1436g (NH 4 ) 2 HPO 4 Dissolve slowly in 5g of water and stir until white AlPO is produced 4 precipitation.

[0061] (2) Continue to add 0.0072g (NH 4 ) 2 HPO 4 and 25g of cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Into the above solution, magnetically stirred at room temperature for 5 min.

[0062] The other steps were the same as in Example 1 to prepare a nickel-rich single crystal positive electrode material with dual-functional interface modification.

Embodiment 3

[0064](1) 0.408g of Al(NO 3 ) 3 9H 2 O and 0.1436g (NH 4 ) 2 HPO 4 Dissolve slowly in 5g of water and stir until white AlPO is produced 4 precipitation.

[0065] (2) Continue to add 0.0288g (NH 4 ) 2 HPO 4 and 25g of cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Into the above solution, magnetically stirred at room temperature for 5 min.

[0066] The other steps were the same as in Example 1 to prepare a nickel-rich single crystal positive electrode material with dual-functional interface modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com