Active layer material and application of active layer material in preparing ternary memory device

A storage device, ternary technology, applied in static memory, digital memory information, information storage and other directions, can solve the problems of poor assembly effect, few types of active layer systems, difficult to achieve, etc., to achieve stable performance, conducive to charge transition, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

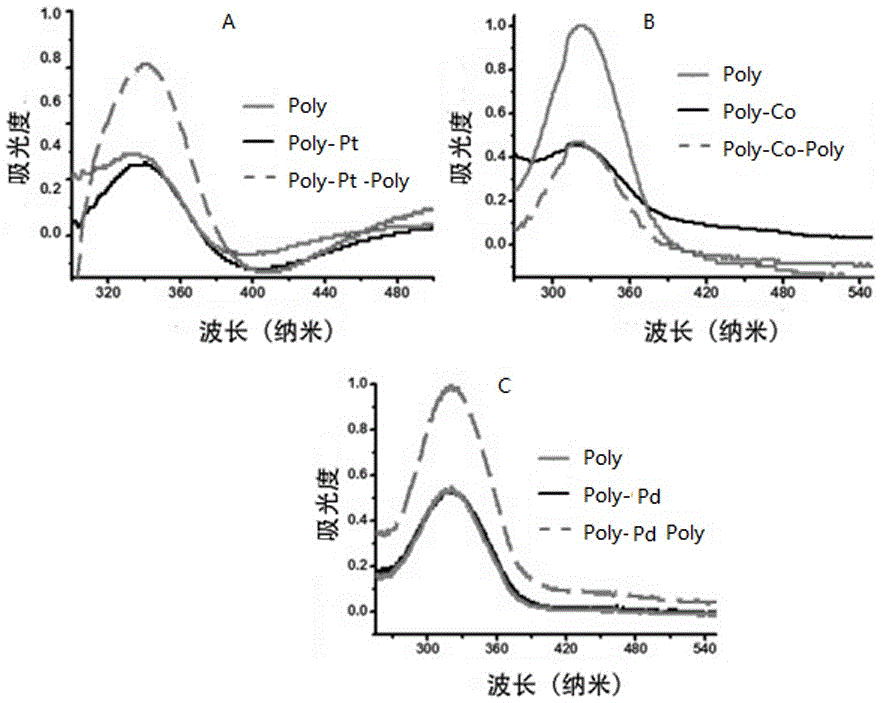

[0035] Poly 4-(4-methacryloyloxy)-azo)pyridine was synthesized by free radical polymerization: 10 mmol (267 mg) of 4-(4-methacryloyloxy)-azo ) pyridine, initiator AIBN (1 mmol, 1.64mg) and 2.5mL of freshly distilled cyclohexanone, under the protection of argon, react at 90°C for 18 hours. After the reaction, the reaction solution was poured into 50ml of methanol to precipitate the product, filtered and dried to obtain poly-4-(4-methacryloyloxy)-azo)pyridine; yield: 57%. IR(KBr): 3423(b), 3033(b), 1751(s), 1589(s), 1494(m), 1195(s), 1101(s), 833(m), 561(w). 1 H NMR (CDCl 3 ): δ=1.0-2.1 (m, 5H), 7.0-7.3 (m, 2H), 7.3-7.7(m, 2H),7.7-8.1 (m, 2H), 8.4-8.9 (m, 2H) (Scheme 5. 1).

Embodiment 1

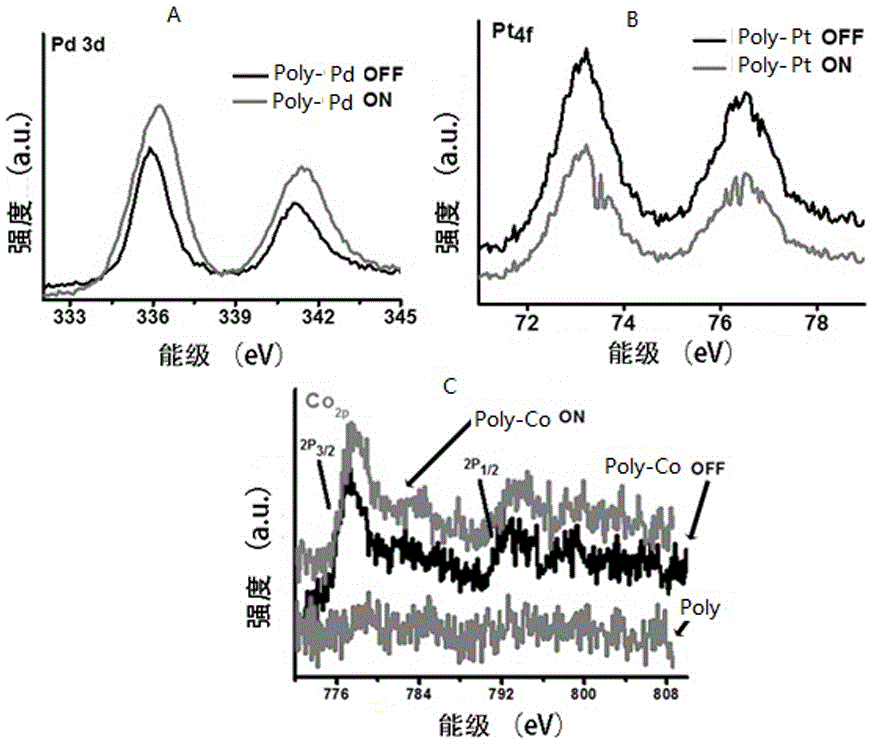

[0037] Put the cut ITO glass into water and add decontamination powder to clean it, then use deionized water to ultrasonically clean it 3 times, then use acetone to ultrasonically clean it 2 times, and finally use absolute ethanol to clean it twice, and dry it for use. Dissolve poly 4-(4-methacryloyloxy)-azo)pyridine in DMF to prepare a polymer solution with a concentration of 15 mg / mL; spin-coat the solution on clean ITO glass to prepare a layer of polymer The thin film of the material was vacuum-dried for 2 hours; the ITO glass with the above-mentioned polymerized film was put into the ethanol solution (15mg / mL) of platinum acetylacetonate for ten minutes, taken out and placed in absolute ethanol for five minutes, and taken out and vacuum-dried for 2 hours; Prepare a layer of polymer film on the above film by solution spin coating, and dry it in vacuum for 2 hours; then evaporate an aluminum electrode to obtain a ternary storage device ITO / Poly-Pt-Poly / Al, ITO: 130nm, polymer...

Embodiment 2

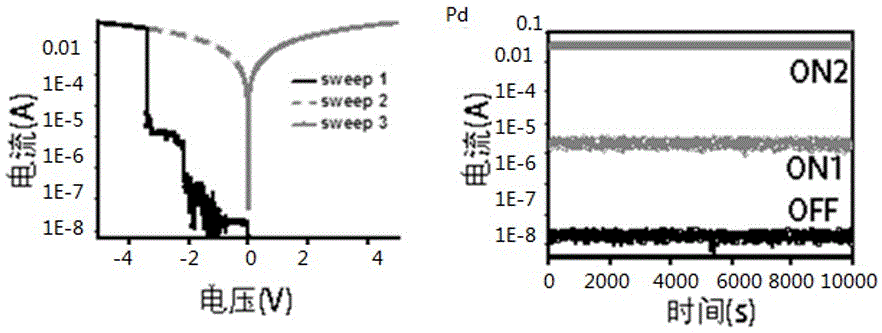

[0039] Put the cut ITO glass into water and add decontamination powder to clean it, then use deionized water to ultrasonically clean it 3 times, then use acetone to ultrasonically clean it 2 times, and finally use absolute ethanol to clean it twice, and dry it for use. Dissolve poly 4-(4-methacryloyloxy)-azo)pyridine in toluene to prepare a polymer solution with a concentration of 15 mg / mL; spin-coat the solution on clean ITO glass to prepare a layer of polymer The thin film of the material was vacuum-dried for 2 hours; the above-mentioned ITO glass prepared with a polymeric film was put into an ethanol solution (10 mg / mL) of palladium acetylacetonate for ten minutes, taken out and put in absolute ethanol for five minutes, and then taken out and vacuum-dried for 2 hours; Prepare a layer of polymer film on the above film by solution spin coating, and dry it in vacuum for 2 hours; then evaporate an aluminum electrode to obtain a ternary storage device ITO / Poly-Pd-Poly / Al, ITO: 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com