Micro hole-aluminum silicate fiber sandwich type composite sound absorption board

A technology of aluminum silicate fiber board and aluminum silicate fiber, which is applied to building components, sound insulation, building structure, etc., can solve the problems of crowding out the maintenance space of the main transformer room, difficult to cover the high frequency range, and narrow frequency band for efficient sound absorption. Achieve the effect of improving sound absorption performance, excellent resistive sound absorption, and optimizing resonance sound absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

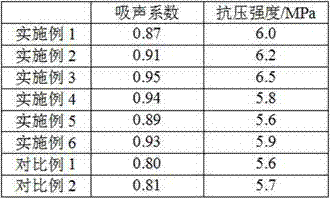

Embodiment 1

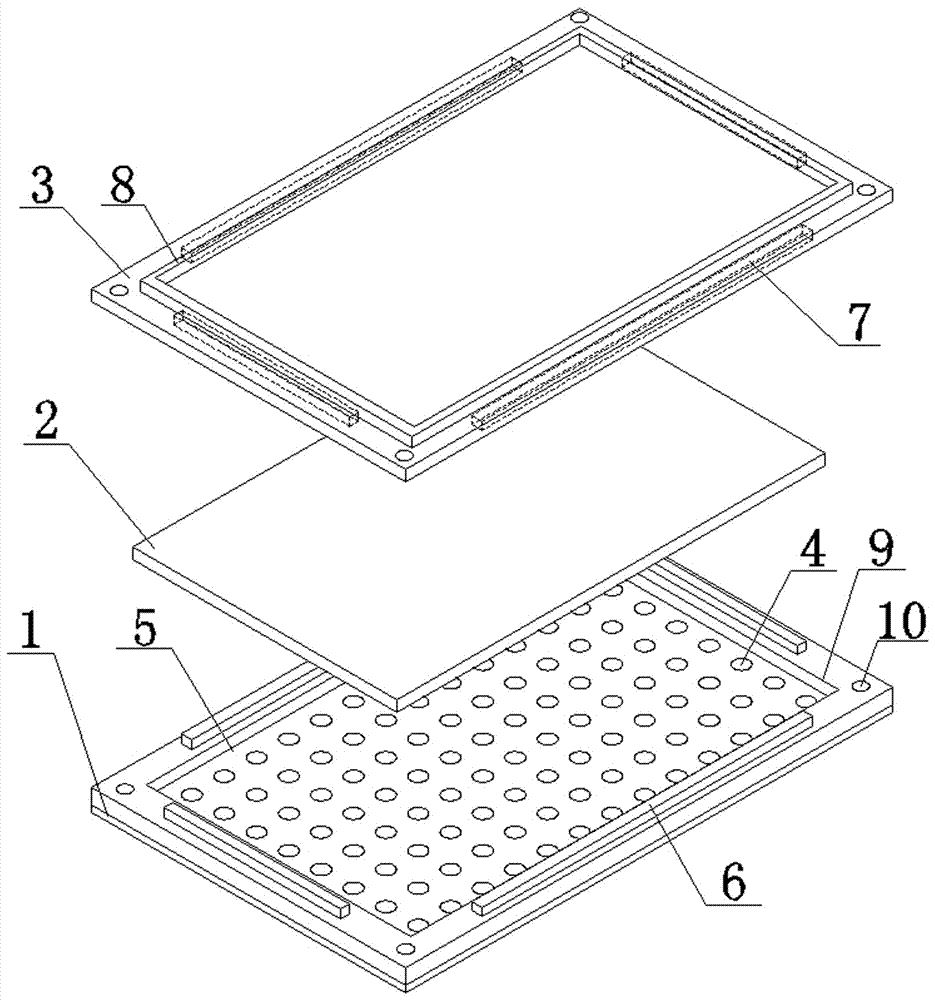

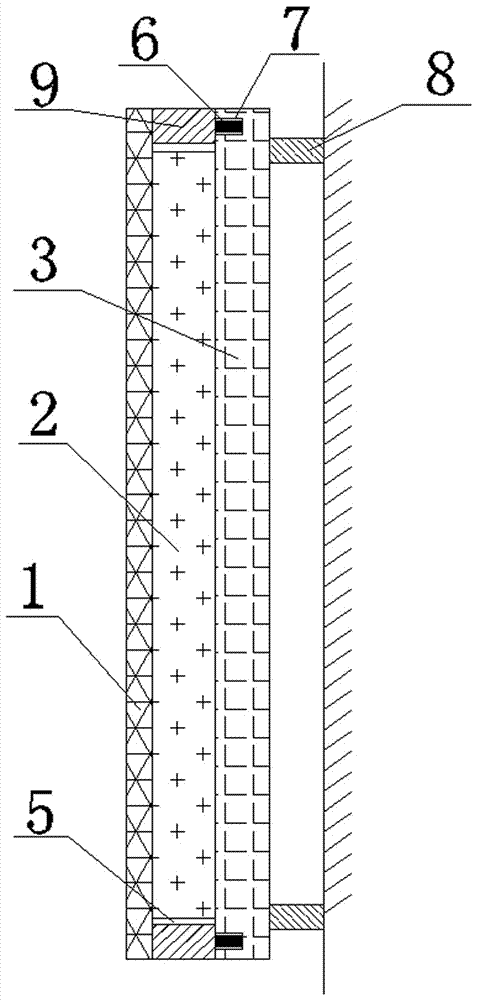

[0030] like figure 1 As shown, a microporous-aluminum silicate fiber sandwich composite sound-absorbing panel, including a micro-perforated plate 1, an aluminum silicate fiber felt 2 and an aluminum silicate fiber board 3 arranged sequentially from the outside to the inside, and the micro-perforated plate 1 is set A plurality of perforations 4, wherein the thickness of the micro-perforated plate 1 can be 0.5-1.5 mm, and the perforation rate is 1-3%. In this embodiment, the thickness of the micro-perforated plate is 1 mm, and the perforation rate is 3%. The aluminum silicate fiber felt 2 The thickness can be 2-6cm, the bulk density is 20-80kg / m 3 , the thickness of aluminum silicate fiber mat 2 in the present embodiment is 2cm, and bulk density is 40kg / m 3 , the thickness of the aluminum silicate fiber sound-absorbing board is 2-4cm, and the bulk density is 140-200kg / m 3 , the thickness of the aluminum silicate fiber sound-absorbing board in this embodiment is 2cm, and the bu...

Embodiment 2

[0039] The structure of the microporous-aluminum silicate fiber sandwich composite sound-absorbing panel in Example 2 is the same as that in Example 1, except that:

[0040] In this embodiment, the thickness of the micro-perforated plate 1 is 0.5 mm, the perforation rate is 2%, the thickness of the aluminum silicate fiber mat 2 is 3 cm, and the bulk density is 40 kg / m 3 , the thickness of the aluminum silicate fiber sound-absorbing panel 3 is 3cm, and the bulk density is 140kg / m 3 ; The thickness of the frame 8 is 4cm.

[0041] Aluminum silicate fiberboard is prepared from the following raw materials in parts by weight: 42 parts of aluminum silicate fiber, 10 parts of glass fiber, 9 parts of asbestos powder, 7 parts of diatomaceous earth, 6 parts of vermiculite powder, 9 parts of sodium phosphate, 16 parts of polyvinyl alcohol Parts, 16 parts of ethylene glycol.

[0042] Wherein the preparation method of aluminum silicate fiber board comprises the following steps:

[0043] ...

Embodiment 3

[0047] Embodiment 3 has the same structure as that of Embodiment 1, except that:

[0048] In this embodiment, the thickness of the micro-perforated plate 1 is 1 mm, the perforation rate is 3%, the thickness of the aluminum silicate fiber mat 2 is 2 cm, and the bulk density is 60 kg / m 3 , the thickness of the aluminum silicate fiber sound-absorbing panel 3 is 2cm, and the bulk density is 160kg / m 3 ; The thickness of the frame 8 is 6cm.

[0049] Aluminum silicate fiberboard is prepared from the following raw materials in parts by weight: 45 parts of aluminum silicate fiber, 9 parts of glass fiber, 10 parts of asbestos powder, 8 parts of diatomaceous earth, 7 parts of vermiculite powder, 10 parts of sodium phosphate, 14 parts of polyvinyl alcohol Parts and 18 parts of ethylene glycol.

[0050] Wherein the preparation method of aluminum silicate fiber board comprises the following steps:

[0051] (1) Mix diatomite, vermiculite powder and ethylene glycol evenly, stir at 50°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com