A high fatigue-resistant nylon composite material for office chairs and its preparation method

A nylon composite material and office seat technology, applied in the field of polymer materials, can solve the problems of easy breakage, failure to meet sustainable development, and low elongation at break of composite materials, so as to improve the phenomenon of whitening and wide coloring The dyeing effect, the effect that the processing method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

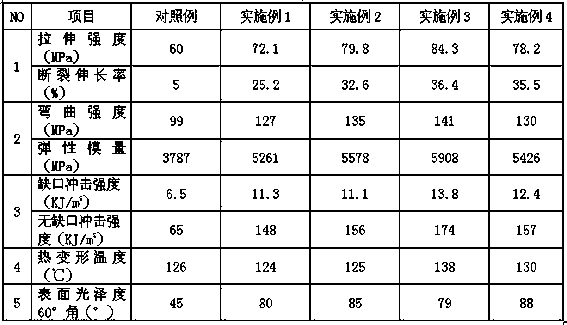

Examples

Embodiment 1

[0036] (1) Treat the surface of the inorganic mineral powder with an aminated silane coupling agent (glycidyl ether oxypropyl trimethoxysilane), first mix 80 parts of inorganic mineral powder (mica) and 20 parts of alcohol with a concentration of 95% Add to the mixer, stir at low speed (450r / min) for 3 minutes, let the alcohol be fully absorbed by the inorganic mineral powder, then add 1 part of silane coupling agent to the mixer, heat to 90°C, stir at high speed (1200r / min) In 10 minutes, the silane coupling agent will be hydrolyzed under the action of heating and alcohol, and the coupling reaction will be carried out with the hydroxyl groups on the surface of the inorganic mineral powder. Agent-modified inorganic mineral powder;

[0037] (2) Mix polyamide 6, chain extender (alternating copolymer of maleic anhydride and ethylene) and inorganic mineral powder in a ratio of 52:1:40 through a mixer for 10 minutes to obtain a homogeneous mixture;

[0038] (3) Raise the temperatu...

Embodiment 2

[0041] (1) Treat the surface of the inorganic mineral powder with an aminated silane coupling agent (aminopropyltriethoxysilane), first add 80 parts of inorganic mineral powder (mica) and 20 parts of alcohol with a concentration of 9% In the mixer, stir at low speed (450r / min) for 3 minutes, let the alcohol be fully absorbed by the inorganic mineral powder, then add 2 parts of silane coupling agent into the mixer, heat to 90°C, stir at high speed (1200r / min) for 10 Minutes, the silane coupling agent will be hydrolyzed under the action of heating and alcohol, and the coupling reaction will be carried out with the hydroxyl group on the surface of the inorganic mineral powder. After the completion, the powder is dried in the powder drying equipment at 100°C to obtain the silane coupling agent Modified inorganic mineral powder;

[0042] (2) Mix polyamide 6, chain extender (epoxy compound: maleic anhydride and ethylene alternating copolymer = 1:1), and inorganic mineral powder in a...

Embodiment 3

[0046] (1) Treat the surface of the inorganic mineral powder with an aminated silane coupling agent (vinyl tris(β-methoxyethoxy) silane), first mix 80 parts of inorganic mineral powder (mica) and 20 parts of alcohol Add to the mixer, stir at low speed (450r / min) for 3 minutes, let the alcohol be fully absorbed by the inorganic mineral powder, then add 2 parts of silane coupling agent into the mixer, heat to 90°C, stir at high speed (1200r / min) In 10 minutes, the silane coupling agent will be hydrolyzed under the action of heating and alcohol, and the coupling reaction will be carried out with the hydroxyl groups on the surface of the inorganic mineral powder. Agent-modified inorganic mineral powder;

[0047] (2) Polyamide 6, chain extender (epoxy compound: alternating copolymer of maleic anhydride and ethylene

[0048] : Isocyanate = 2:1:1), inorganic mineral powder according to the ratio of 51:2:40 and mixed by a mixer for 10 minutes to obtain a uniform mixture;

[0049] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com