Grafted polypheylene ether resin and preparation method thereof

A technology of polyphenylene ether resin and mixed resin, which is applied in the field of polyphenylene ether resin, can solve the problems of poor mechanical properties and easy crosslinking of polyphenylene ether resin, and achieve improved tensile strength, uniform concentration distribution, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

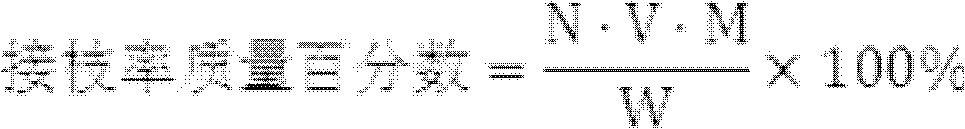

Method used

Image

Examples

Embodiment 1

[0029] (1) Be the poly-2,6-dimethyl-1,4-phenylene ether that intrinsic viscosity is 38ml / g, under air atmosphere, carry out pre-irradiation with β ray on electron accelerator device, pre-irradiation dose is 10kGy to obtain pre-irradiated poly 2,6-dimethyl-1,4-phenylene ether;

[0030] (2) 85 parts by mass of the poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether 15 parts of resin mass parts are added in the high-speed mixer together, mix, obtain mixed resin;

[0031] (3) The mixed resin obtained in step (2) is added in the main hopper of the Haake reaction type twin-screw extruder, and the mass parts are 10 parts of acrylic acid and 2 parts of p-benzoquinone through the Haake reaction type twin-screw extruder The liquid feeding port of machine is injected, carries out reactive extruding grafting, and the screw rod diameter of described Haake reactive type twin-screw extruder is 24mm, and length-to-diameter ratio is 40, a...

Embodiment 2

[0039] (1) The poly 2,6-dimethyl-1,4-phenylene ether resin that intrinsic viscosity is 42ml / g, under air atmosphere, carry out pre-irradiation with β ray on electron accelerator device, pre-irradiation dose 40kGy to obtain pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether;

[0040] (2) 65 parts by mass of the poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether 35 parts of resin mass parts are added in the high-speed mixer together, mix, obtain mixed resin;

[0041](3) Add the mixed resin obtained in step (2) into the main hopper of the SHJ-30 reactive twin-screw extruder, and the temperature of each section from the feeding port to the die is 200, 220, 240, 260, 270, 280, 280, 285, 285, 290, 280°C, speed 75 rpm, inject 0.5 parts by mass of acrylic acid and 0.05 parts of triphenyl phosphate through the liquid feeding port of SHJ-30 reactive twin-screw extruder , carry out reactive extrusion grafting, and the reaction m...

Embodiment 3

[0046] (1) Poly 2,6-dimethyl-1,4-phenylene ether resin with an intrinsic viscosity of 40ml / g is pre-irradiated with β-rays on an electron accelerator device under an air atmosphere, and the pre-irradiation The dose is 30kGy to obtain pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether;

[0047] (2) 75 parts by mass of the pre-irradiated poly-2,6-dimethyl-1,4-phenylene ether resin obtained in step (1) and poly-2,6-dimethyl-1,4-phenylene ether resin 25 parts by mass are added together in a high-speed mixer and mixed to obtain a mixed resin;

[0048] (3) Add the mixed resin obtained in step (2) into the main hopper of the SHJ-30 reactive twin-screw extruder, and the temperature of each section from the feeding port to the die is 200, 230, 250, 270, 270, 280, 285, 285, 285, 290, 280°C, speed 120 rev / min, put 5 parts by mass of acrylic acid and 1 part by mass of triphenyl phosphate through the liquid of SHJ-30 reactive twin-screw extruder The feeding port is injected to carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com