Developing cleaning agent and preparation method thereof

A cleaning agent and defoaming agent technology, applied in the field of cleaning agents, can solve the problems affecting the yield of finished products and appearance problems, and achieve the effect of reducing the proportion of poor quality and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

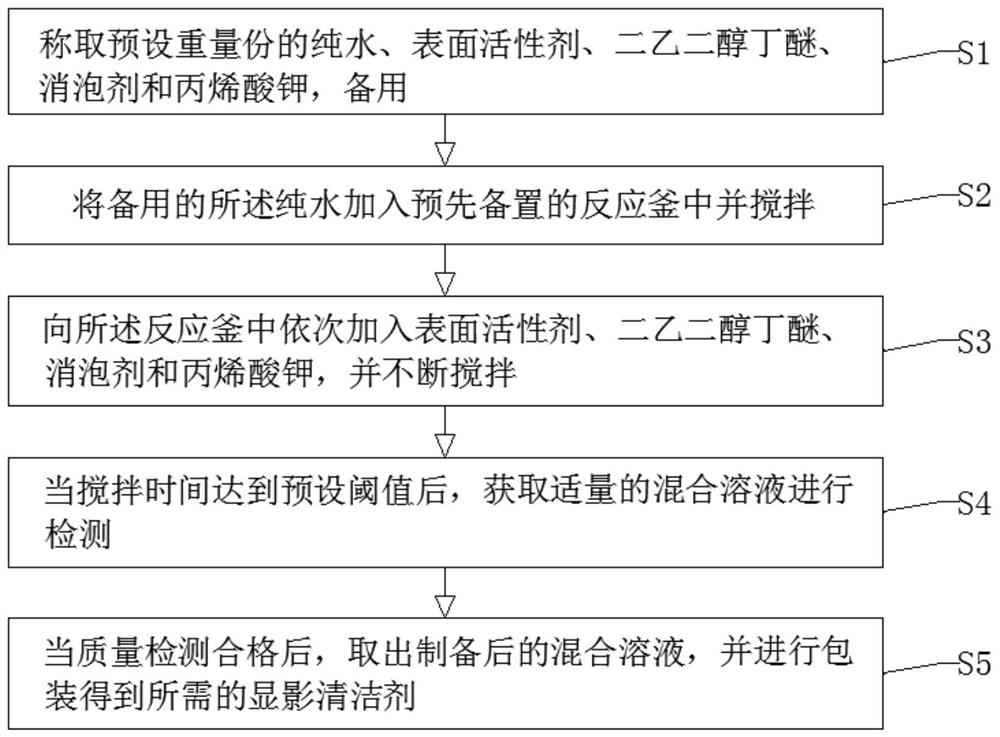

Method used

Image

Examples

Embodiment 1

[0037] A development cleaning agent, the development cleaning agent is made up of the following raw materials of weight part:

[0038] 75 parts of pure water, 10 parts of surfactant, 1 part of diethylene glycol butyl ether, 0.05 part of defoamer and 1 part of potassium acrylate.

Embodiment 2

[0040] A development cleaning agent, the development cleaning agent is made up of the following raw materials of weight part:

[0041] 81.90 parts of pure water, 15.00 parts of surfactant, 2.00 parts of diethylene glycol butyl ether, 0.10 parts of defoamer and 2.00 parts of potassium acrylate.

Embodiment 3

[0043] A development cleaning agent, the development cleaning agent is made up of the following raw materials of weight part:

[0044] 85 parts of pure water, 20 parts of surfactant, 3 parts of diethylene glycol butyl ether, 0.15 parts of defoamer and 3 parts of potassium acrylate.

[0045] In order to further understand the above-mentioned technical solution of the present invention, the product advantages and corresponding principles of the developer cleaning agent are now described in detail.

[0046] The developer cleaner of the present invention has the following advantages:

[0047] 1) The main components are inhibitors + antifoaming agents, which can prevent the secondary polymerization of the photoresist in the dry film / ink after development and keep the tank clean;

[0048] 2) It can inhibit the anti-adhesion of film scraps to the board surface and improve product yield;

[0049] 3) Long-term use, keep the tank body free of dirt adhesion, no tank cleaning agent is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com