Bamboo powder/poly(butylene succinate)/starch biodegradable plastic and preparation method thereof

A technology of polybutylene succinate and biodegradable plastics, which is applied in the field of biodegradable new materials, can solve the problems of high production costs, achieve safe sources, wide sources, and increase the effect of composite grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

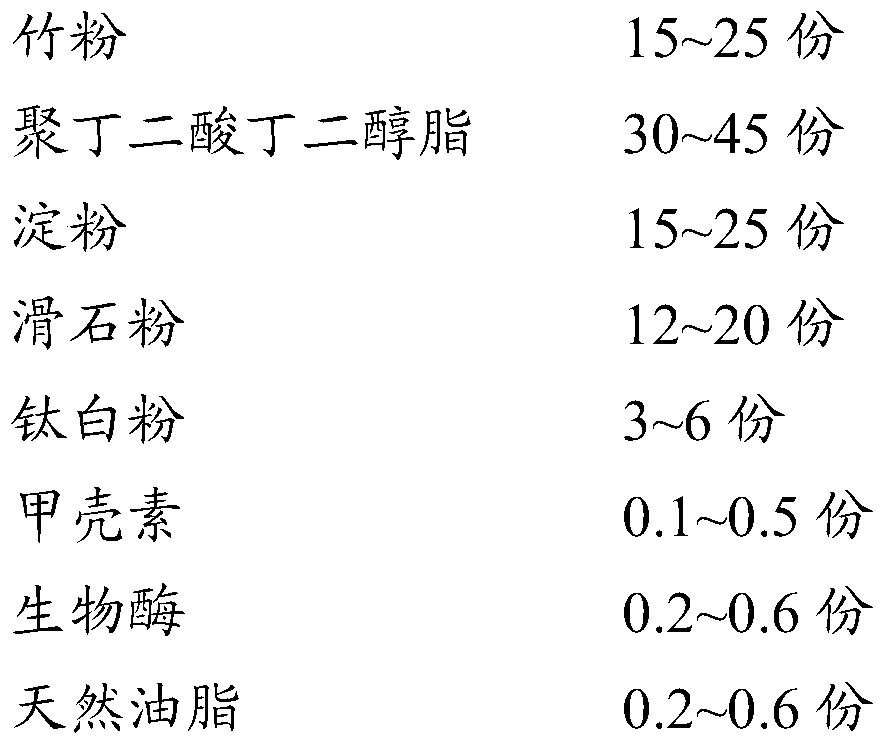

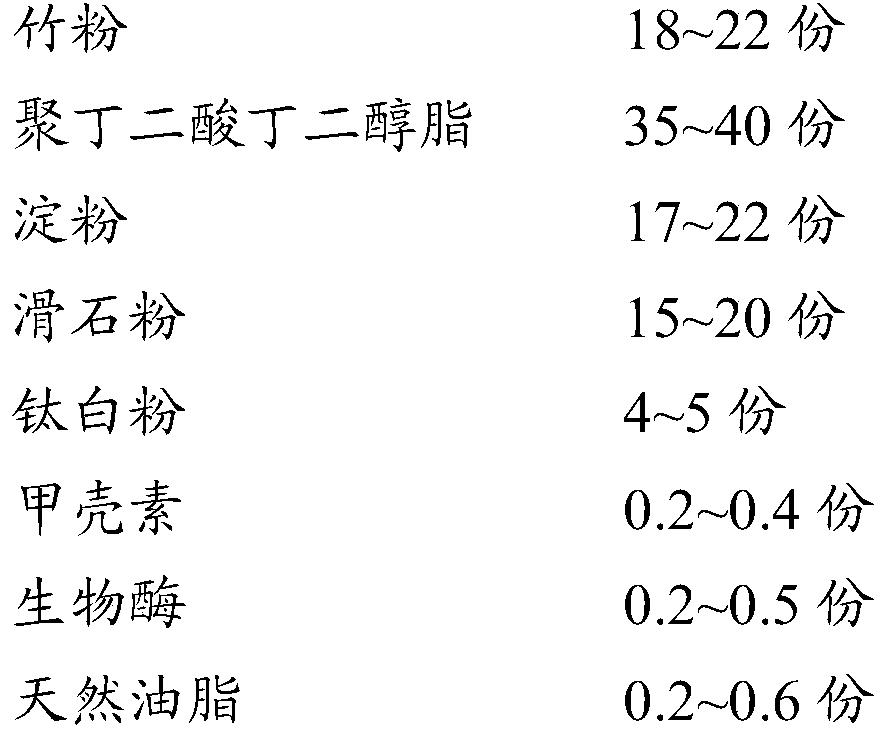

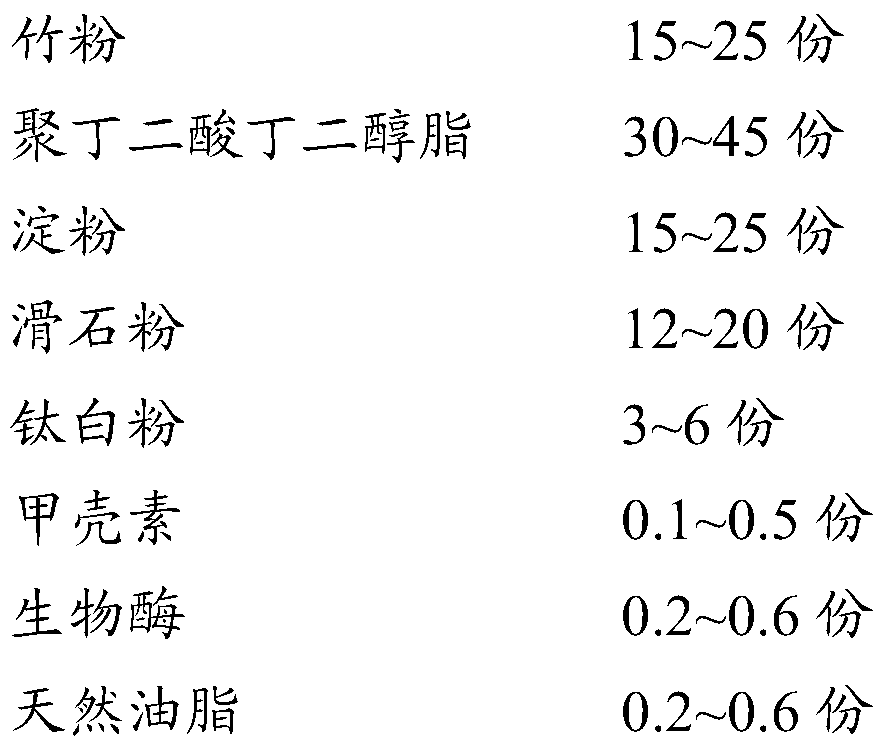

Method used

Image

Examples

Embodiment 1

[0029] Bamboo powder polybutylene succinate starch biodegradable plastics are prepared as follows:

[0030] Step 1: Put 20 parts of starch, 0.4 parts of biological enzyme, and 4.5 parts of titanium dioxide into a high-speed grinder and mix evenly to obtain a mixed material A;

[0031] Step 2: put 15 parts of bamboo powder into a high-speed grinder and grind it to 3000-4000 meshes, transfer the ground bamboo powder directly to a kneading mixer, add the mixed material A and 0.3 parts of natural oil successively for mixing ;

[0032] Step 3: Add 37.5 parts of polybutylene succinate, 17 parts of 6000-mesh talc powder, and 0.3 parts of chitin to the kneading mixer in step 2 to continue mixing, control the mixing temperature to 130 °C, and mix The mixing time is 2 to 4 hours. The raw materials are further refined and dispersed in the mixing chamber through rotor friction and shearing to obtain the mixed material B;

[0033] Step 4: put the mixed material B into a bioreactor throug...

Embodiment 2

[0037] Bamboo powder polybutylene succinate starch biodegradable plastics are prepared as follows:

[0038] Step 1: Put 20 parts of starch, 0.4 parts of biological enzyme, and 4.5 parts of titanium dioxide into a high-speed grinder and mix evenly to obtain a mixed material A;

[0039] Step 2: Put 20 parts of bamboo powder into a high-speed grinder and grind to 3000-4000 mesh, transfer the ground bamboo powder directly to a kneading mixer, add the mixed material A and 0.3 parts of natural oil in turn for mixing ;

[0040] Step 3: Add 37.5 parts of polybutylene succinate, 17 parts of 6000-mesh talc powder, and 0.3 parts of chitin to the kneading mixer in step 2 to continue mixing, control the mixing temperature to 130 °C, and mix The mixing time is 2 to 4 hours. The raw materials are further refined and dispersed in the mixing chamber through rotor friction and shearing to obtain the mixed material B;

[0041] Step 4: put the mixed material B into a bioreactor through a forced...

Embodiment 3

[0045] Bamboo powder polybutylene succinate starch biodegradable plastics are prepared as follows:

[0046]Step 1: Put 20 parts of starch, 0.4 parts of biological enzyme, and 4.5 parts of titanium dioxide into a high-speed grinder and mix evenly to obtain a mixed material A;

[0047] Step 2: put 25 parts of bamboo powder into a high-speed grinder and grind to 3000-4000 meshes, transfer the ground bamboo powder directly to a kneading mixer, add the mixed material A and 0.3 parts of natural oil successively for mixing ;

[0048] Step 3: Add 37.5 parts of polybutylene succinate, 17 parts of 6000-mesh talc powder, and 0.3 parts of chitin to the kneading mixer in step 2 to continue mixing, control the mixing temperature to 130 °C, and mix The mixing time is 2 to 4 hours. The raw materials are further refined and dispersed in the mixing chamber through rotor friction and shearing to obtain the mixed material B;

[0049] Step 4: put the mixed material B into a bioreactor through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com