Polyolefin/polystyrene blend-based wood plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and polystyrene, which is applied in the field of wood-plastic composite materials, can solve the problems of poor interface adhesion, high production cost, and low dosage, so as to improve interface adhesion, improve mechanical properties, and promote Effect of grafting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

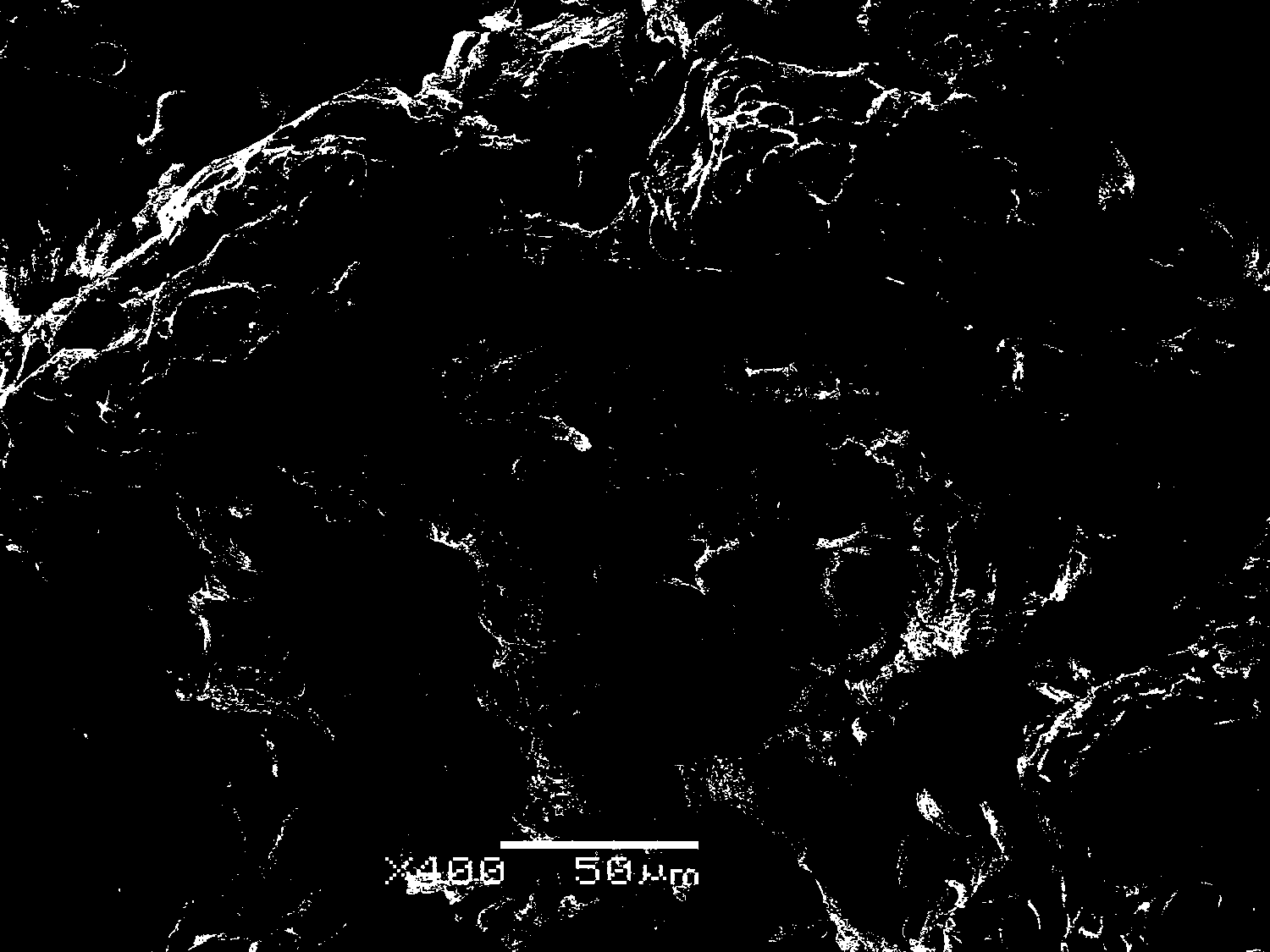

Embodiment 1

[0019] Weigh 100 parts of a mixture of polypropylene / polystyrene (80 / 20), 0.3 parts of dicumyl peroxide, and 3 parts of maleic anhydride, and dissolve the initiator and maleic anhydride in acetone to prepare 20% solutions respectively , and then mix it with the plastic mixture evenly, and store it open to allow the solvent to evaporate completely; add 50 parts of wood fiber, 0.75 parts of stearic acid and styrene into a high-speed mixer, and the molar ratio of styrene to maleic anhydride is 1:1, and the Mix for 3 minutes, then add the previously mixed plastic mixture, and mix evenly for 5 minutes; put the mixed material into the twin-screw extruder, the extrusion temperature is 170~195°C, adjust the host and feeding speed to make the material in The residence time in the extruder was 2 minutes and 53 seconds, and the polyolefin / polystyrene blend-based wood-plastic composite material was obtained after extrusion. The resulting wood-plastic composite material was injection molde...

Embodiment 2

[0021] Weigh 100 parts of a mixture of polyethylene / polystyrene (80 / 20), 0.3 parts of dicumyl peroxide, and 3 parts of maleic anhydride, and dissolve the initiator and maleic anhydride in acetone to prepare 20% solutions respectively , and then mix it with the plastic mixture evenly, and store it open to allow the solvent to evaporate completely; add 50 parts of wood fiber, 0.75 parts of stearic acid and styrene into a high-speed mixer, and the molar ratio of styrene to maleic anhydride is 0.5:1, and the mixture is uniform Mix for 3 minutes, then add the previously mixed plastic mixture, and mix evenly for 5 minutes; put the mixed material into the twin-screw extruder, the extrusion temperature is 170~195°C, adjust the host and feeding speed to make the material in The residence time in the extruder was 2 minutes and 51 seconds, and the polyolefin / polystyrene blend-based wood-plastic composite material was obtained after extrusion. The resulting wood-plastic composite material...

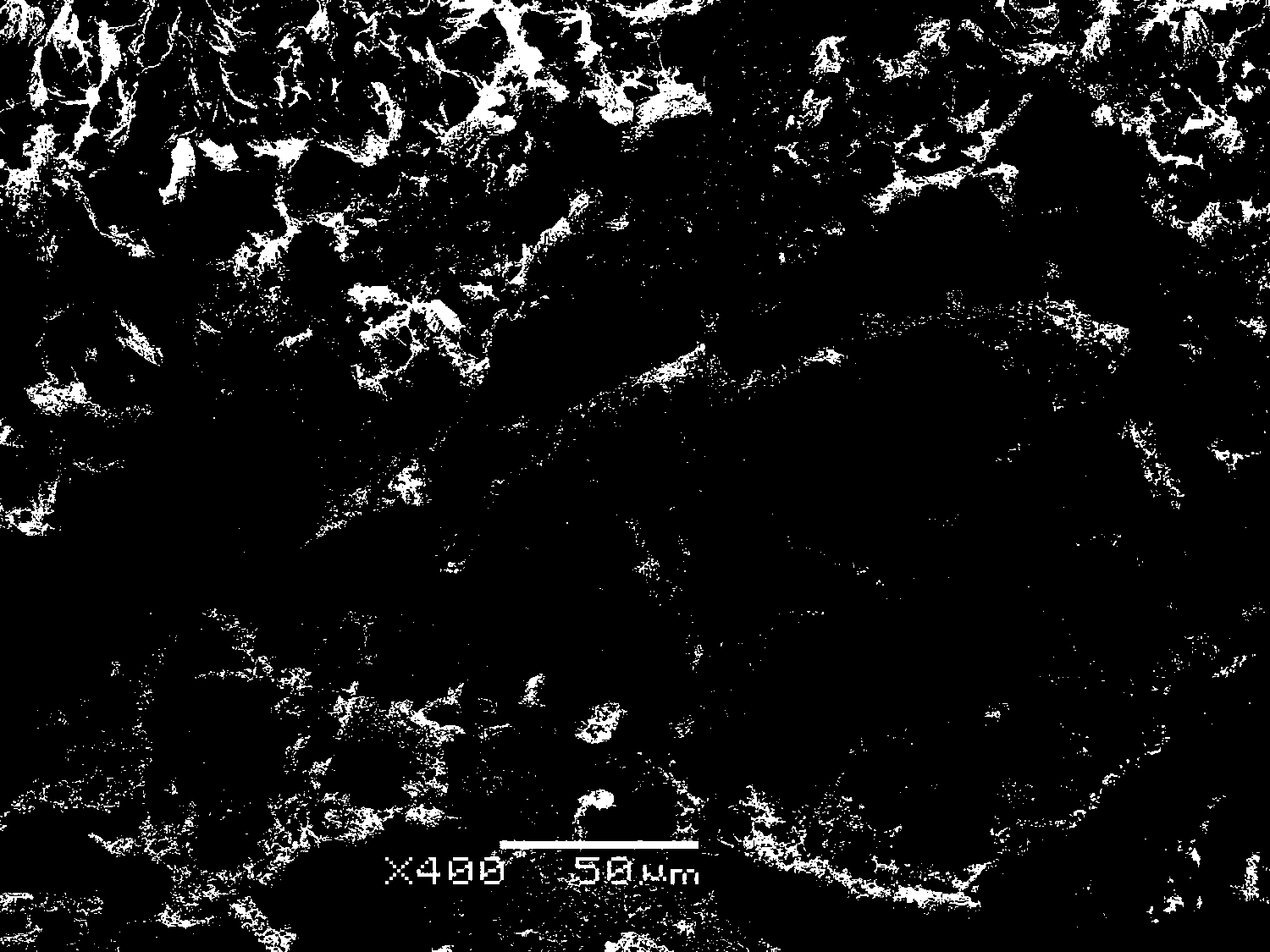

Embodiment 3

[0023] Weigh 100 parts of a mixture of polyethylene / polystyrene (80 / 20), 0.3 parts of dicumyl peroxide, and 3 parts of maleic anhydride, and dissolve the initiator and maleic anhydride in acetone to prepare 20% solutions respectively , and then mix it with the plastic mixture evenly, and store it open to allow the solvent to evaporate completely; add 50 parts of wood fiber, 0.75 parts of stearic acid and styrene into a high-speed mixer, and the molar ratio of styrene to maleic anhydride is 1:1, and the Mix for 3 minutes, then add the previously mixed plastic mixture, and mix evenly for 5 minutes; put the mixed material into the twin-screw extruder, the extrusion temperature is 170~195°C, adjust the host and feeding speed to make the material in The residence time in the extruder was 2 minutes and 51 seconds, and the polyolefin / polystyrene blend-based wood-plastic composite material was obtained after extrusion. The resulting wood-plastic composite material was injection molded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com