St/BA Copolymerization-modified oxidized starch adhesive and preparation method thereof

A technology of oxidized starch and copolymerization modification, used in adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of high moisture absorption, unsatisfactory performance and low strength of oxidized starch adhesives. Conducive to grafting reaction, uniform viscosity and low moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

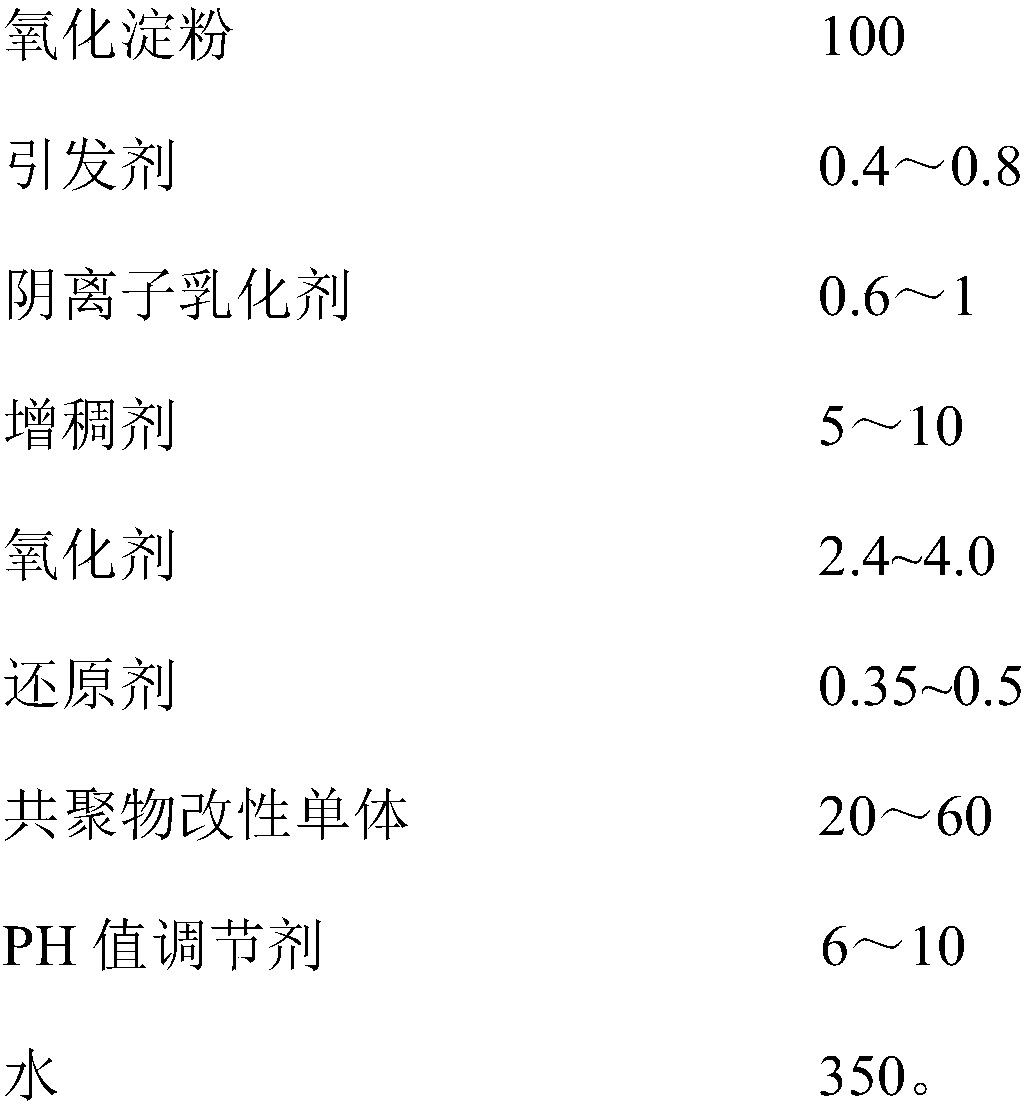

[0028] A kind of St / BA copolymerization modified oxidized starch adhesive, by weight, is made by comprising following raw material:

[0029]

[0030] making process:

[0031] 1) Add 100g of oxidized starch, 0.6g of sodium dodecylbenzenesulfonate and 2.4g of hydrogen peroxide into 300g of water to dissolve and make starch latex, and heat to 80°C for gelatinization for 30min, and control the concentration of oxidized starch at 25wt%, Prepare gelatinized starch solution;

[0032] (2) Dissolving 0.35 g of sodium sulfite in 10 g of water to obtain a reducing agent aqueous solution, adding the reducing agent aqueous solution to the gelatinized starch solution prepared in (1), and keeping it warm for 15 minutes to obtain the gelatinized starch solution (2);

[0033] (3) 0.4g ammonium persulfate is added to dissolve in 10g water to obtain initiator aqueous solution;

[0034] (4) 10g styrene and 10g butyl acrylate are mixed uniformly to obtain a mixed monomer;

[0035] (5) Add 10...

Embodiment 2

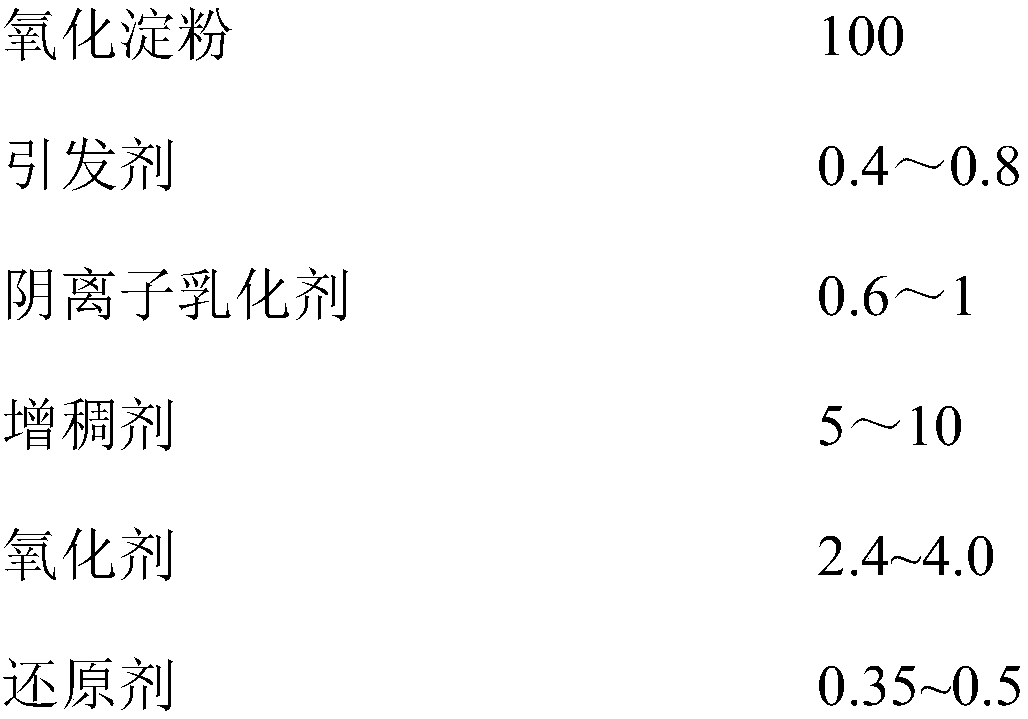

[0039] A kind of St / BA copolymerization modified oxidized starch adhesive, by weight, is made by comprising following raw material:

[0040]

[0041] making process:

[0042] 1) Add 100g of oxidized starch, 0.8g of sodium dodecylbenzenesulfonate and 3.0g of hydrogen peroxide into 300g of water to dissolve and make starch latex, and heat to 80°C for gelatinization for 30min, and control the concentration of oxidized starch at 25wt%, Prepare gelatinized starch solution;

[0043] (2) dissolving 0.4 g of sodium sulfite in 10 g of water to obtain a reducing agent aqueous solution, adding the reducing agent aqueous solution into the gelatinized starch solution prepared in (1), and keeping it warm for 15 minutes to obtain the gelatinized starch solution (2);

[0044] (3) 0.6g ammonium persulfate is added to dissolve in 10g water to obtain initiator aqueous solution;

[0045] (4) 15g styrene and 30g butyl acrylate are mixed uniformly to obtain a mixed monomer;

[0046] (5) Add 5...

Embodiment 3

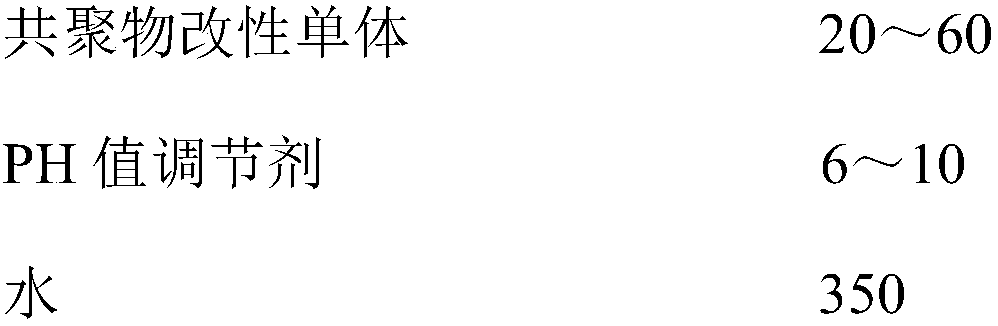

[0050] A kind of St / BA copolymerization modified oxidized starch adhesive, by weight, is made by comprising following raw material:

[0051]

[0052]

[0053] making process:

[0054] 1) Add 100g of oxidized starch, 1.0g of sodium dodecylbenzenesulfonate and 3.5g of hydrogen peroxide into 300g of water to dissolve and make starch latex, and heat to 80°C for gelatinization for 30min, and control the concentration of oxidized starch at 25wt%, Prepare gelatinized starch solution;

[0055] (2) Dissolving 0.5 g of sodium sulfite in 10 g of water to obtain a reducing agent aqueous solution, adding the reducing agent aqueous solution to the gelatinized starch solution prepared in (1), and keeping it warm for 15 minutes to obtain the gelatinized starch solution (2);

[0056] (3) 0.5g ammonium persulfate is added to dissolve in 10g water to obtain initiator aqueous solution;

[0057] (4) 20g styrene and 40g butyl acrylate are mixed uniformly to obtain mixed monomers;

[0058] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com