Novel hydrophilic soil-releasing finishing agent and preparation method thereof

A kind of easy decontamination finishing, hydrophilic technology, applied in the direction of fiber treatment, textile and paper making, etc., can solve the problems of poor washing resistance of fabrics, influence on other properties of fabrics, etc., to improve the easy decontamination effect and good affinity , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

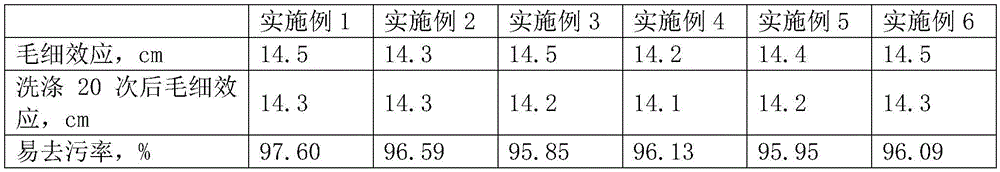

Examples

Embodiment 1

[0048] A novel hydrophilic and easy decontamination finishing agent, in parts by weight, comprises the following components:

[0049] 10 parts of methyl acrylate, 10 parts of ethyl acrylate,

[0050] 5 parts of methacrylic acid, 2 parts of water-soluble silicone oil,

[0051] 6 parts of sodium di(2-ethylhexyl)sulfosuccinate,

[0052] 3 parts of carboxymethyl cellulose, 0.5 parts of tourmaline powder,

[0053] Polyethylene oxide / propylene oxide block polyether 5 parts,

[0054] 0.02 parts of dispersant, 1 part of initiator, 30 parts of deionized water.

[0055] Its preparation method comprises the following steps:

[0056] (1) Mix and stir the tourmaline powder, dispersant and deionized water evenly, under the power of 500W, ultrasonicate for 2 hours, transfer to a ball mill, and ball mill for 6 hours to obtain a uniform dispersion;

[0057] (2) Mix methyl acrylate, ethyl acrylate, methacrylic acid and deionized water, stir evenly, heat up to 50°C, add bis(2-ethylhexyl) so...

Embodiment 2

[0060] A novel hydrophilic and easy decontamination finishing agent, in parts by weight, comprises the following components:

[0061] 15 parts of methyl acrylate, 20 parts of ethyl acrylate,

[0062] 10 parts of methacrylic acid, 5 parts of water-soluble silicone oil,

[0063] 12 parts of sodium di(2-ethylhexyl)sulfosuccinate,

[0064] 7 parts of carboxymethyl cellulose, 1 part of tourmaline powder,

[0065] Polyethylene oxide / propylene oxide block polyether 8 parts,

[0066] 0.05 parts of dispersant, 2 parts of initiator, 50 parts of deionized water.

[0067] Its preparation method comprises the following steps:

[0068] (1) Mix and stir the tourmaline powder, dispersant and deionized water evenly, under the power of 500W, ultrasonicate for 5 hours, transfer to a ball mill, and ball mill for 12 hours to obtain a uniform dispersion;

[0069](2) Mix methyl acrylate, ethyl acrylate, methacrylic acid and deionized water, stir evenly, heat up to 60°C, add bis(2-ethylhexyl) so...

Embodiment 3

[0072] A novel hydrophilic and easy decontamination finishing agent, in parts by weight, comprises the following components:

[0073] 12 parts of methyl acrylate, 15 parts of ethyl acrylate,

[0074] 10 parts of methacrylic acid, 3.5 parts of water-soluble silicone oil,

[0075] 9 parts of sodium di(2-ethylhexyl)sulfosuccinate,

[0076] 3 parts of carboxymethyl cellulose, 0.5 parts of tourmaline powder,

[0077] Polyethylene oxide / propylene oxide block polyether 6 parts,

[0078] 0.04 parts of dispersant, 1 part of initiator, 50 parts of deionized water.

[0079] Its preparation method comprises the following steps:

[0080] (1) Mix and stir tourmaline powder, dispersant and deionized water evenly, under the power of 500W, ultrasonic 3h, transfer to a ball mill, ball mill for 7h, to obtain a uniform dispersion;

[0081] (2) Mix methyl acrylate, ethyl acrylate, methacrylic acid and deionized water, stir evenly, heat up to 55°C, add bis(2-ethylhexyl) sodium sulfosuccinate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com