Process for preparing high purity hydrochloric acid by circularly absorbing hydrogen chloride by-product

A high-purity hydrochloric acid and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of difficulty in meeting the qualified standards of trace organic impurities, excessive hydrogen chloride tail gas, and high cost, and achieve good industrial application prospects and economic value Improvement, the effect of equipment investment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

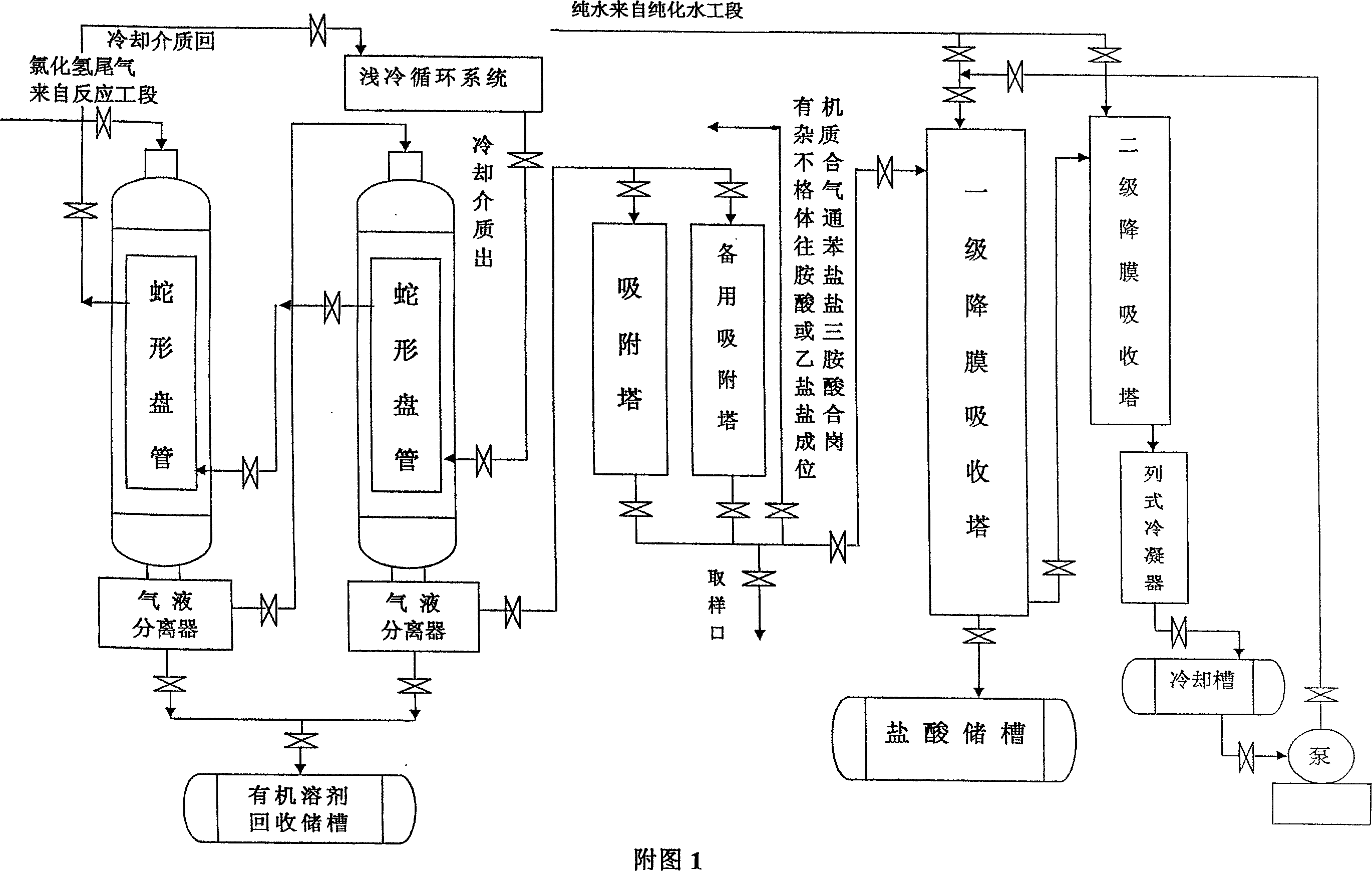

[0027] The equipment installation is shown in Figure 1. The main equipment models and specifications are as follows: (1) Snake tube glass condenser, model LNQ, 5m 2 ×2, produced by Changshu Deshun Chemical Equipment Co., Ltd.; (2) Adsorption tower, customized, material: reinforced polypropylene, specification: φ60cm×h200cm, built-in granular activated carbon 50Kg, model: ZS-15 granular activated carbon for solvent recovery, Manufactured by Nanjing Zhengsen Chemical Industry Co., Ltd.; (3) YKX round hole graphite falling film absorber, produced by Changzhou Fuhua Chemical Heat Exchange Equipment Co., Ltd.

[0028] The hydrogen chloride tail gas comes from the synthesis section of isopropyl isocyanate, and the reaction solvent is o-dichlorobenzene, which is reacted three times. Benzene 120L. The freezing medium of the shallow cold circulation system is ethanol, and the temperature is -10°C.

[0029] Including the following process steps:

[0030] (1) Shallow cold separation: ...

Embodiment 2

[0036] The equipment installation is shown in Figure 1. The main equipment models and specifications are as follows: (1) Snake tube glass condenser, model LNQ, 5m 2×2, produced by Changshu Deshun Chemical Equipment Co., Ltd.; (2) Adsorption tower, customized, material: reinforced polypropylene, specification: φ60cm×h200cm, built-in granular activated carbon 50Kg, model: ZS-15 granular activated carbon for solvent recovery, Produced by Nanjing Zhengsen Chemical Industry Co., Ltd.; (3) Modified graphite polypropylene falling film absorber, model: SPX-10-A, produced by Zhejiang Jiande Science and Technology Experimental Factory.

[0037] The hydrogen chloride tail gas comes from the synthesis section of isopropyl isocyanate, and the reaction solvent is o-dichlorobenzene, which is reacted three times. Benzene 120L. The freezing medium of the shallow cold circulation system is ethanol, and the temperature is -10°C.

[0038] Including the following process steps:

[0039] (1) Sha...

Embodiment 3

[0045] Equipment and its installation are the same as in Embodiment 2. The hydrogen chloride tail gas comes from the synthesis section of phenyl isocyanate, and the solvent used is chlorobenzene, which is reacted twice, and the feeding amount of each reaction is: 93Kg of aniline, 100Kg of bis(trichloromethyl)carbonate, 3Kg of tetrabutylurea, Chlorobenzene 250L; the freezing medium of the shallow cold circulation system is ethanol, and the temperature is -25°C.

[0046] Including the following process steps:

[0047] (1) Shallow cold separation: the hydrogen chloride tail gas from the phenyl isocyanate synthesis section is condensed through a two-stage coiled glass condenser with -25°C freezing medium ethanol in the jacket, and then passed through a gas-liquid separator to remove large Part of the high boiling point organic impurities chlorobenzene;

[0048] (2) Gas phase adsorption: remove the gas containing a small amount of organic impurities from the gas-liquid separator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com