Synthesis of quasi chitosan-fatty acid salt and development of green surfactant

A surfactant and surface active technology, applied in transportation and packaging, dissolution, chemical instruments and methods, etc., can solve problems such as difficult economy, difficulty in raw material collection and product extraction, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

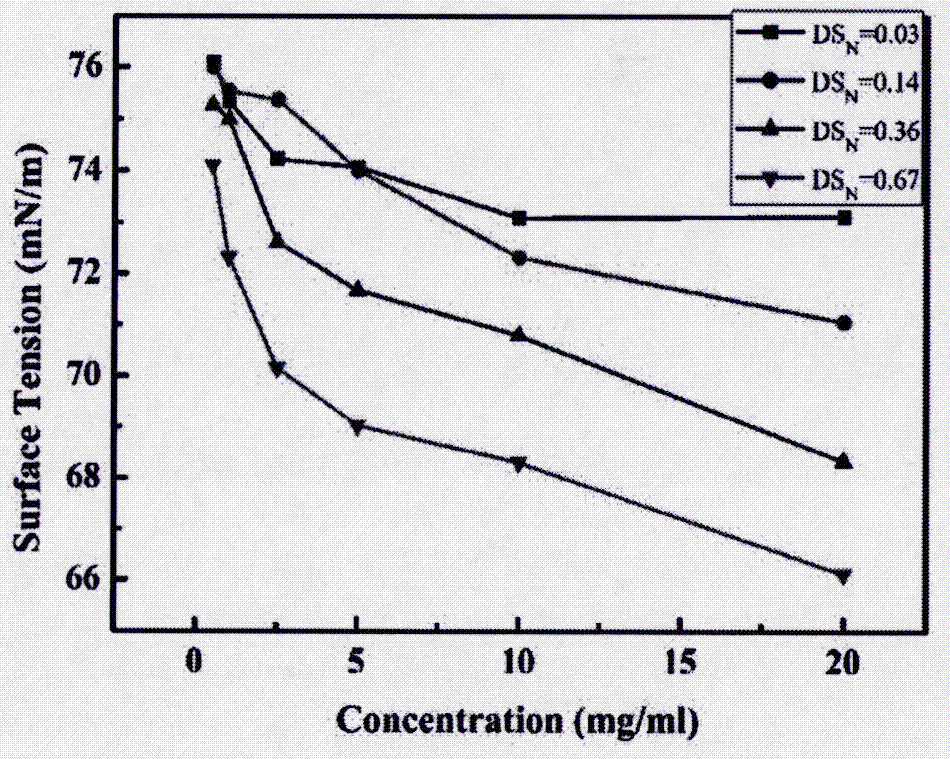

[0062] Example 1: Preparation of surface active system with raw materials of different ammonia substitution degrees

[0063] Table 3: Elemental analysis data table of 6 amino-cellulose obtained under different conditions

[0064]

[0065] Weigh the corresponding amount of 6-aminocellulose in a hydrothermal reaction kettle, add 30ml of distilled water to prepare an aqueous solution, add an accurate amount of conjugated linoleic acid, the salt-forming equivalent ratio of the two additions is 2.3:1, and control the reaction temperature After reacting for 4 hours, samples were taken and aged to obtain a 6-aminocellulose-conjugated linoleate mixture aqueous solution.

[0066] Use the K100 automatic surface tensiometer to measure the synthetic product aqueous solution series of raw materials with different ammoniated substitution degrees, draw the surface tension curve, and obtain the critical micelle concentration of the synthesized products from raw materials with different amm...

Embodiment 2

[0068] Example 2: Preparation of 6-aminocellulose with microcrystalline cellulose as biomass raw material (the degree of sulfonated substitution is 1.41, and the degree of ammoniated substitution is 0.36), and soybean oil is used as raw material to prepare mixed conjugated cellulose by alkali isomerization Preparation of 6-aminocellulose-fatty acid salts with linoleic acid and different mass ratios

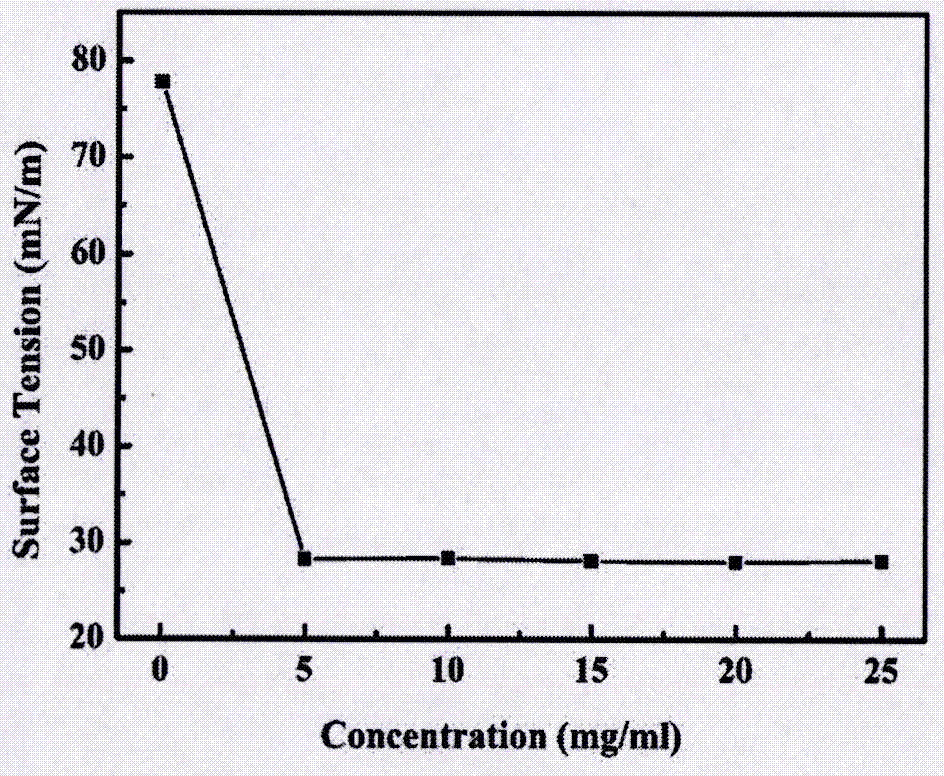

[0069] Weigh the following 6-aminocelluloses of different qualities according to the proportion, prepare them into an aqueous solution, add 1g of conjugated linoleic acid uniformly, and the compounding mass ratios are 1:1:, 2:1, 3:1, 4:1, 5:1, 6:1, stirring and reacting at 30°C for 5 hours in a reaction kettle to obtain an aqueous solution of 6-aminocellulose-fatty acid salt mixture, and the pH value of the solution was adjusted at 8-9. The product properties were determined as Image 6 , 7 shown.

[0070] from Image 6 , 7 We can see that with the increase of the amount of 6...

Embodiment 3

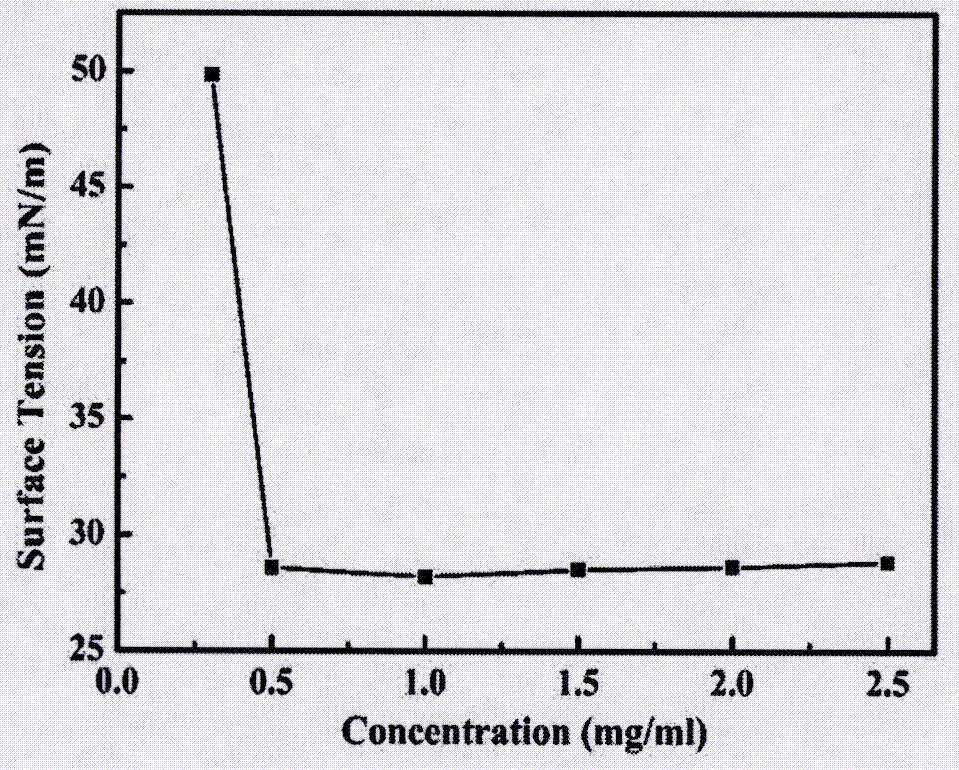

[0071] Example 3: Preparation of 6-aminocellulose with microcrystalline cellulose as biomass raw material (the degree of substitution by sulfonation is 1.41, and the degree of substitution by ammoniation is 0.36), and soybean oil is used as raw material to prepare conjugated aminocellulose by alkali isomerization Preparation of 6-aminocellulose-conjugated linoleate with oleic acid and different reaction temperatures

[0072] Weigh exactly 4g of 6-aminocellulose, prepare it into an aqueous solution, add 1g of conjugated linoleic acid, and the reaction temperature is 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, 90°C, 100°C, React in the reactor for 4 hours to obtain an aqueous solution of 6-aminocellulose-conjugated linoleate mixture. The pH of the solution was adjusted to 8-9. The product properties were determined as Figure 8 , 9 shown.

[0073] from Figure 8 , 9 We can find that with the increase of reaction temperature, the surface tension and critical micelle concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com