Orderly controllable surface-reinforced Raman scattering active substrate and preparation method thereof

A surface-enhanced Raman, active substrate technology, applied in the field of laser Raman spectroscopy detection, can solve the problems of limited application in the field of molecular sensing, difficulty in large-area mass production, cumbersome procedures, etc., and achieve high surface-enhanced Raman scattering effect, The effect of good substrate stability and low technical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the structure-ordered and controllable silver nanometer surface-enhanced Raman scattering substrate proposed by the present invention comprises the following steps:

[0019] (1) Put the aluminum sheet into distilled water and acetone successively for super vibration to remove the adsorbed impurities on the surface.

[0020] (2) Put the aluminum sheet as the anode into the polishing solution and carry out electrochemical polishing for 3 minutes under the condition of DC constant voltage 15V, wherein the polishing solution is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5.

[0021] (3) The pretreated aluminum sheet is corroded by a two-step oxidation method: the aluminum sheet is used as the anode, the molybdenum sheet is used as the cathode, the temperature is maintained at 10°C, and the constant voltage is oxidized in 0.5mol / L oxalic acid solution. The first step is to oxidize for 2 hours, and then put it into a mixe...

Embodiment 1

[0024] (1) Put the aluminum sheet into distilled water and acetone successively for super vibration to remove the adsorbed impurities on the surface.

[0025] (2) Then put the aluminum sheet as the anode into the polishing solution and carry out electrochemical polishing for 3 minutes under the condition of DC constant voltage 15V, in which the polishing solution is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5.

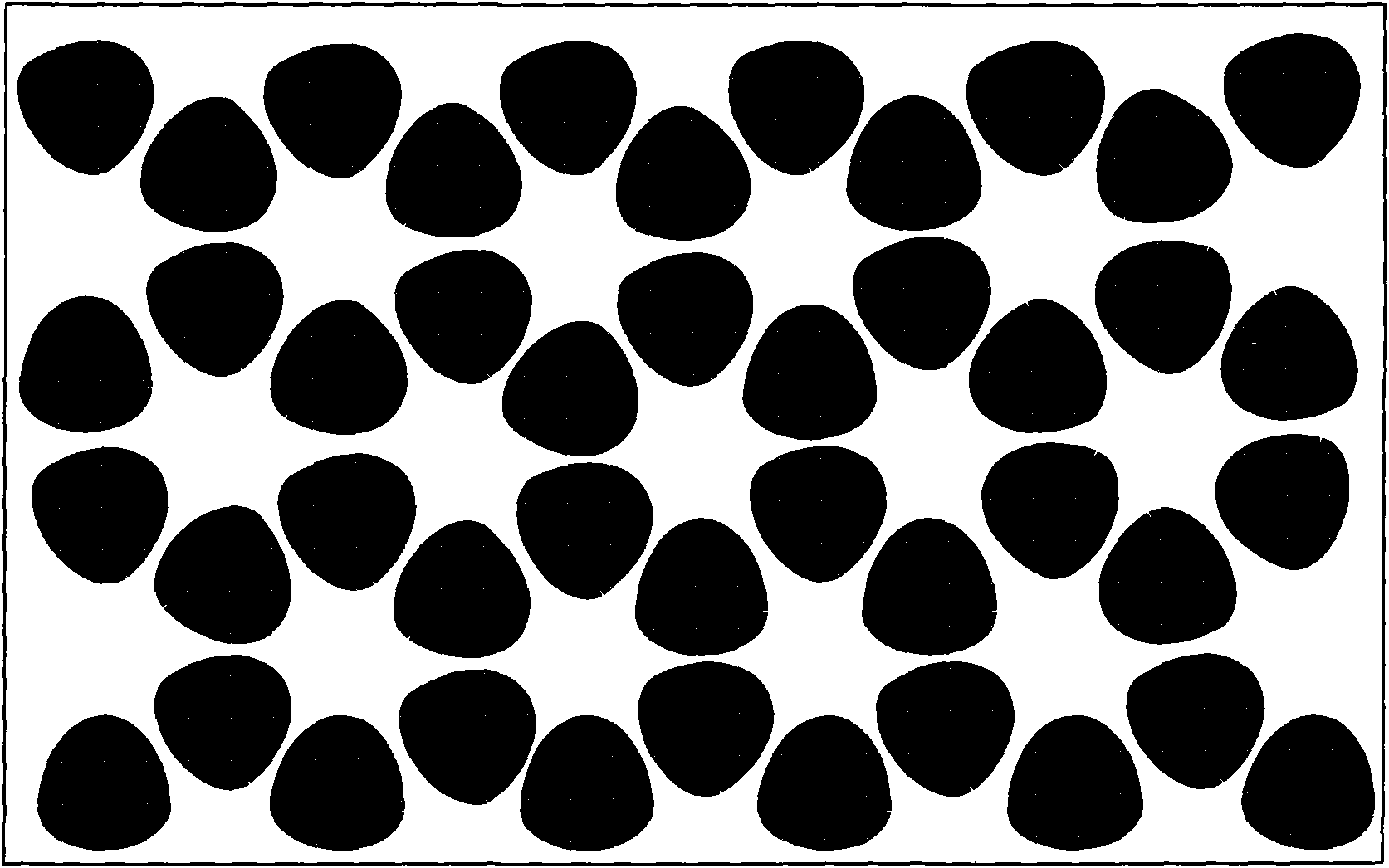

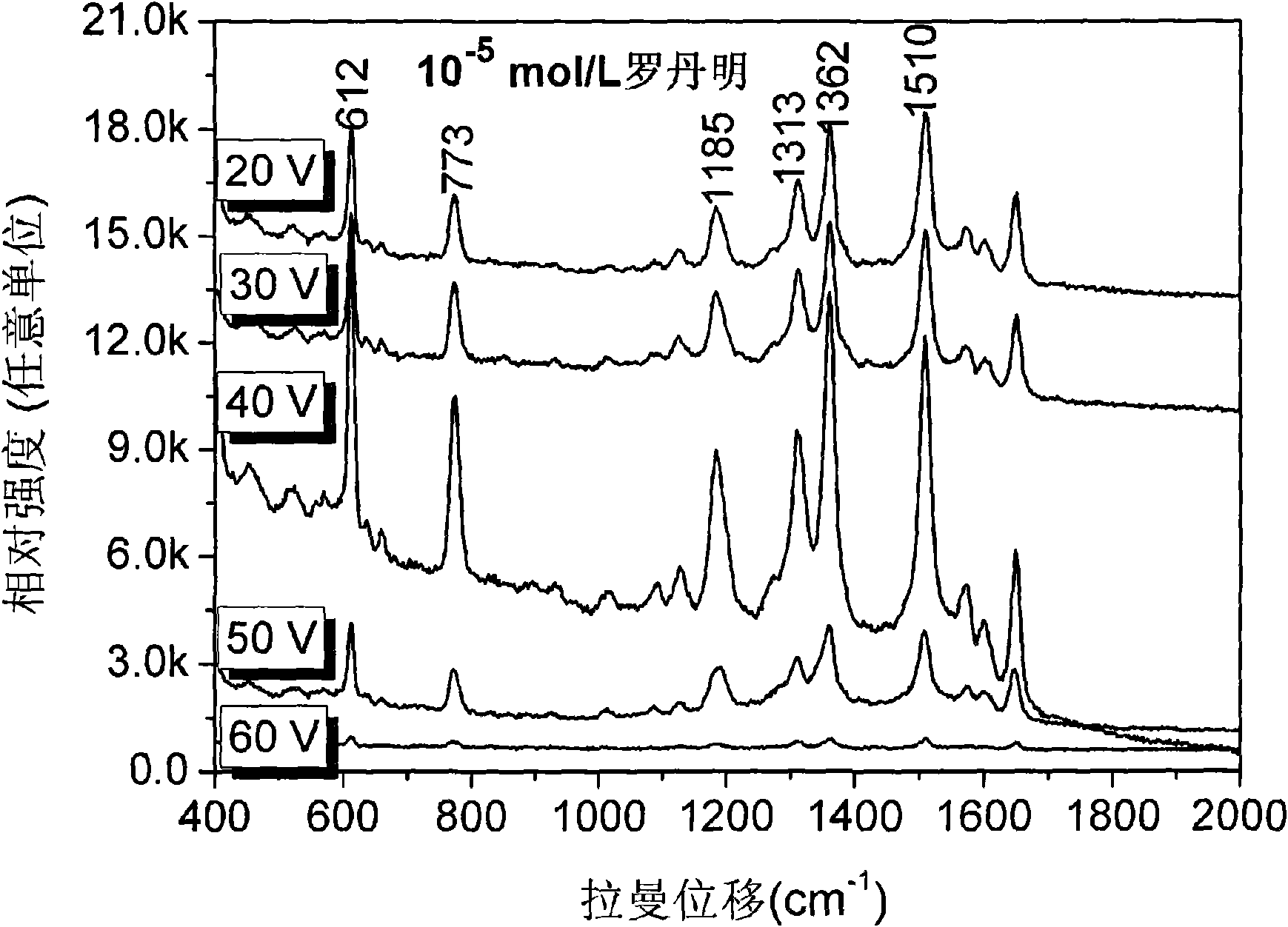

[0026] (3) The pretreated aluminum sheet is corroded by a two-step oxidation method: the aluminum sheet is used as the anode, the molybdenum sheet is used as the cathode, the constant voltage is set to 40V, the temperature is maintained at 10°C, and the oxalic acid solution is 0.5mol / L. oxidation. The first step is oxidized for 2 hours, then put it into a mixed solution of 1.8wt.% chromic acid and 6wt.% phosphoric acid in an equal volume ratio, react at 75°C for 2 hours, and repeat the first step oxidation process to obtain porous alumina...

Embodiment 2

[0029] (1) Put the aluminum sheet into distilled water and acetone successively for super vibration to remove the adsorbed impurities on the surface.

[0030] (2) Then put the aluminum sheet as the anode into the polishing solution and carry out electrochemical polishing for 3 minutes under the condition of DC constant voltage 15V, in which the polishing solution is a mixed solution of perchloric acid and ethanol with a volume ratio of 1:5.

[0031] (3) The pretreated aluminum sheet is corroded by a two-step oxidation method: the aluminum sheet is used as the anode, the molybdenum sheet is used as the cathode, the constant voltage is set to 50V, the temperature is maintained at 10°C, and the corrosion is carried out in 0.5mol / L oxalic acid solution oxidation. The first step is oxidized for 2 hours, then put it into a mixed solution of 1.8wt.% chromic acid and 6wt.% phosphoric acid in an equal volume ratio, react at 75°C for 2 hours, and repeat the first step oxidation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com