Solid acid catalysis and supercritical extraction coupled furfural preparation and apparatus

A solid acid catalyzed and supercritical technology, which is applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of mass transfer efficiency decline, and achieve the goals of reduced environmental pollution, convenient operation, and reduced equipment corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

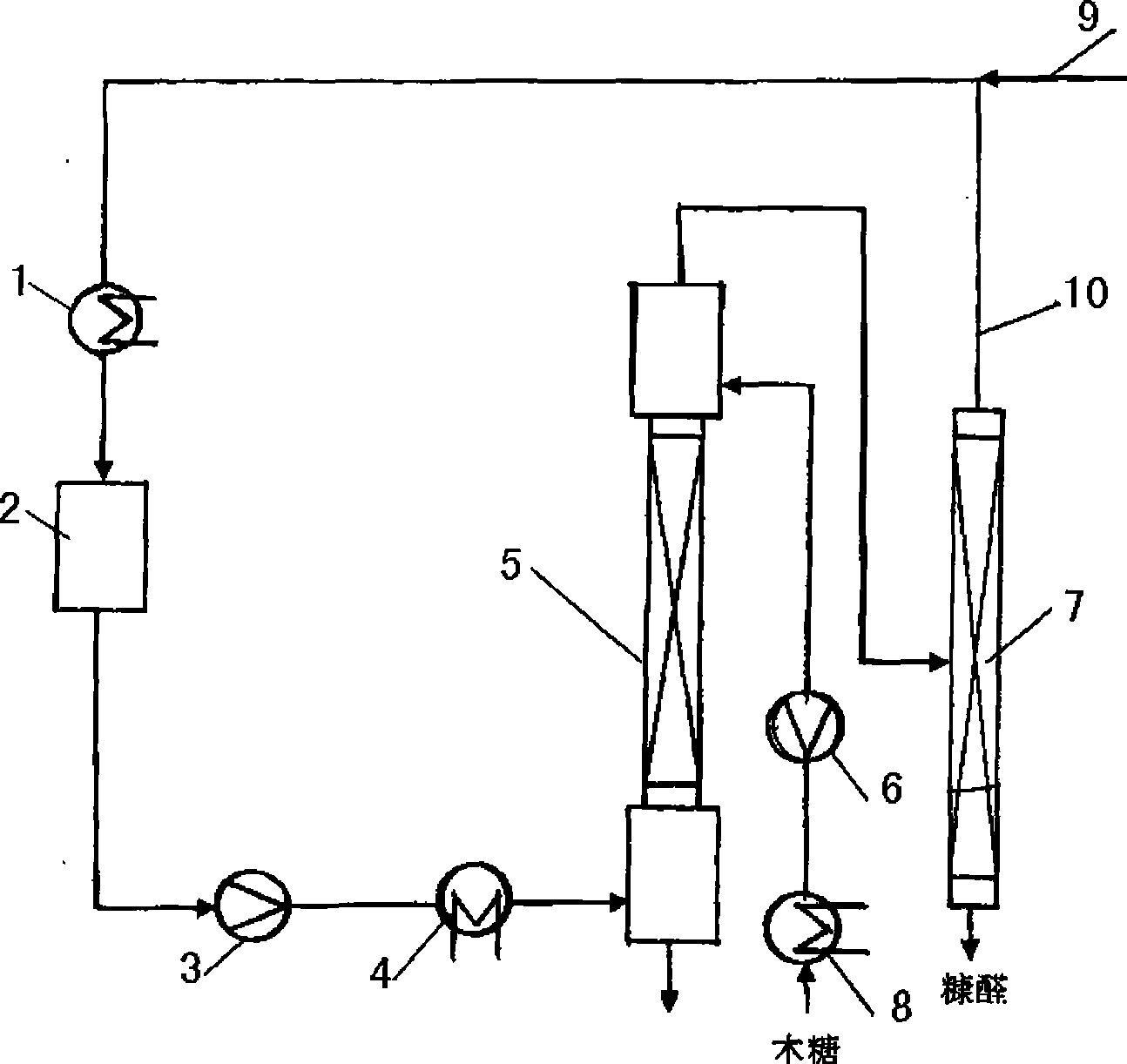

[0037] exist figure 1 The reaction is carried out in the novel packing extraction reaction tower shown. The inner diameter of the tower is 50mm, and the height of the tower is 900mm. CO 2 From the storage tank, it enters the reaction tower through the compression pump 3 and the preheater 4, and adjusts the CO 2 The flow keeps CO in the column 2 The pressure is 7.8MPa, and the xylose aqueous solution with a mass percentage concentration of 20% is passed through, and the flow rate is 30ml / min. The catalyst is filled SO 4 2- / TiO 2 , The total mass of the catalyst in the tower is 1800g. Tower CO 2 Countercurrent continuous contact with xylose solution over the catalyst. The xylose aqueous solution that feeds in is preheated, and makes it temperature be 170 ℃, and the outer jacket of the tower is kept warm so that the temperature in the tower exceeds 160 ℃. The conversion rate was 92%, the selectivity was 80%, and the yield was 73.6%.

Embodiment 2

[0039] exist figure 1 The reaction is carried out in the novel packing extraction reaction tower shown. The inner diameter of the tower is 50mm, and the height of the tower is 900mm. CO 2 From the storage tank, it enters the reaction tower through the compression pump 3 and the preheater 4, and adjusts the CO 2 The flow keeps CO in the column 2 The pressure is 7.2 MPa, and the xylose aqueous solution with a mass percentage concentration of 5% is passed through, and the flow rate is 30 ml / min. The catalyst is filled SO 4 2- / ZrO 2 , The total mass of the catalyst in the tower is 1800g. , CO within the tower 2 Countercurrent continuous contact with xylose solution over the catalyst. The xylose aqueous solution that feeds in is preheated, and makes its temperature be 180 ℃, and the outer jacket of the tower is kept warm so that the temperature inside the tower exceeds 170 ℃. The conversion rate was 89%, the selectivity was 79%, and the yield was 70.3%.

Embodiment 3

[0041] exist figure 1 The reaction is carried out in the novel packing extraction reaction tower shown. The inner diameter of the tower is 50mm, and the height of the tower is 900mm. CO 2 From the storage tank, it enters the reaction tower through the compression pump 3 and the preheater 4, and adjusts the CO 2 The flow keeps CO in the column 2 The pressure is 8.0MPa, and the xylose aqueous solution with a mass percentage concentration of 10% is passed through, and the flow rate is 30ml / min. The catalyst is a faujasite molecular sieve treated by filling and molding, and the total mass of the catalyst in the tower is 1800g. Tower CO 2 Countercurrent continuous contact with xylose solution over the catalyst. The xylose aqueous solution that feeds in is preheated, makes it temperature be 200 ℃, and the outer jacket of the tower is kept warm so that the temperature inside the tower exceeds 190 ℃. The conversion was 94%, the selectivity was 81%, and the yield was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com