Recycling method for catalytic degradation of waste PET

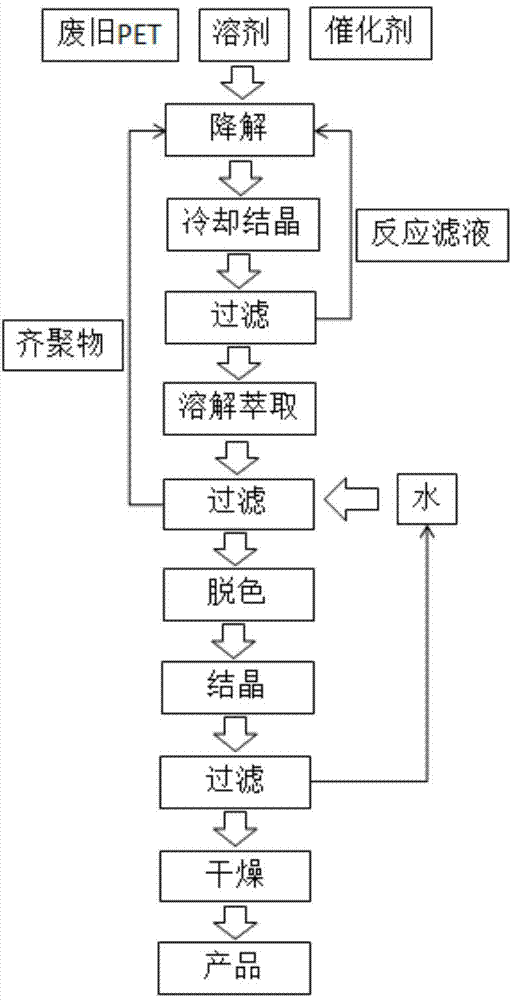

A catalyst and degradation reaction technology, applied in the field of catalytic degradation of waste PET recycling, can solve the problems of high cost and high cost of separation series equipment, and achieve the effects of shortening production cycle, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

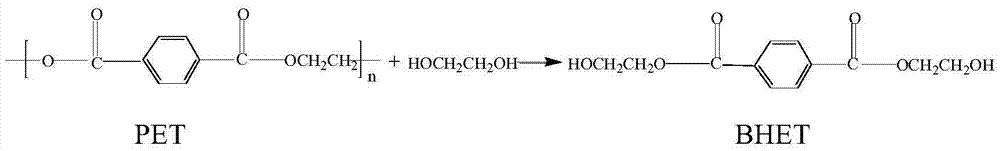

Method used

Image

Examples

Embodiment 1

[0043] In the built reaction kettle equipped with a thermometer, a circulating condensing device, and a mixer, a certain amount of PET bottle flakes and alcoholysis solvent EG are added to the reaction kettle, and heating, stirring and circulating condensed water are started. When the temperature reached 180°C, [bmim]Br was added and the reaction timed for 2.0h. After the reaction, pour the material liquid into the container, stir and cool down to room temperature. The cooled reaction solution was separated by centrifuge filtration. The filtered solid was poured into a reaction kettle, dissolved in water at a mass ratio of 10 / 1 to PET, and stirred. After dissolving, filter and separate by centrifuge. After dissolving, separate the obtained filtrate into the reaction kettle, start stirring and add a certain amount of activated carbon for decolorization. The decolorized material liquid is filtered and separated by a centrifuge, and the filter residue is activated carbon, whic...

Embodiment 2

[0045] In the built reaction kettle equipped with a thermometer, a circulating condensing device, and a mixer, a certain amount of PET bottle flakes and alcoholysis solvent EG are added to the reaction kettle, and heating, stirring and circulating condensed water are started. When the temperature reached 170°C, [bmim]Br was added and the reaction timed for 0.5h. After the reaction, pour the material liquid into the container, stir and cool down to room temperature. The cooled reaction solution was separated by centrifuge filtration. The filtered solid was poured into a reaction kettle, dissolved in water at a mass ratio of 10 / 1 to PET, and stirred. After dissolving, filter and separate by centrifuge. After dissolving, separate the obtained filtrate into the reaction kettle, start stirring and add a certain amount of activated carbon for decolorization. The decolorized material liquid is filtered and separated by a centrifuge, and the filter residue is activated carbon, whic...

Embodiment 3

[0047] In the built reaction kettle equipped with a thermometer, a circulating condensing device, and a mixer, a certain amount of PET bottle flakes and alcoholysis solvent EG are added to the reaction kettle, and heating, stirring and circulating condensed water are started. When the temperature reached 160°C, [bmim]Br was added and the reaction timed for 0.5h. After the reaction, pour the material liquid into the container, stir and cool down to room temperature. The cooled reaction solution was separated by centrifuge filtration. The filtered solid was poured into a reaction kettle, dissolved in water at a mass ratio of 10 / 1 to PET, and stirred. After dissolving, filter and separate by centrifuge. After dissolving, separate the obtained filtrate into the reaction kettle, start stirring and add a certain amount of activated carbon for decolorization. The decolorized material liquid is filtered and separated by a centrifuge, and the filter residue is activated carbon, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com