Infrared nondestructive testing and imaging method based on array laser source and used for structure surface cracks

An infrared non-destructive testing and structural surface technology, applied in material defect testing and other directions, can solve the problems of slow detection speed and complex system, and achieve the effect of intuitive results, high sensitivity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

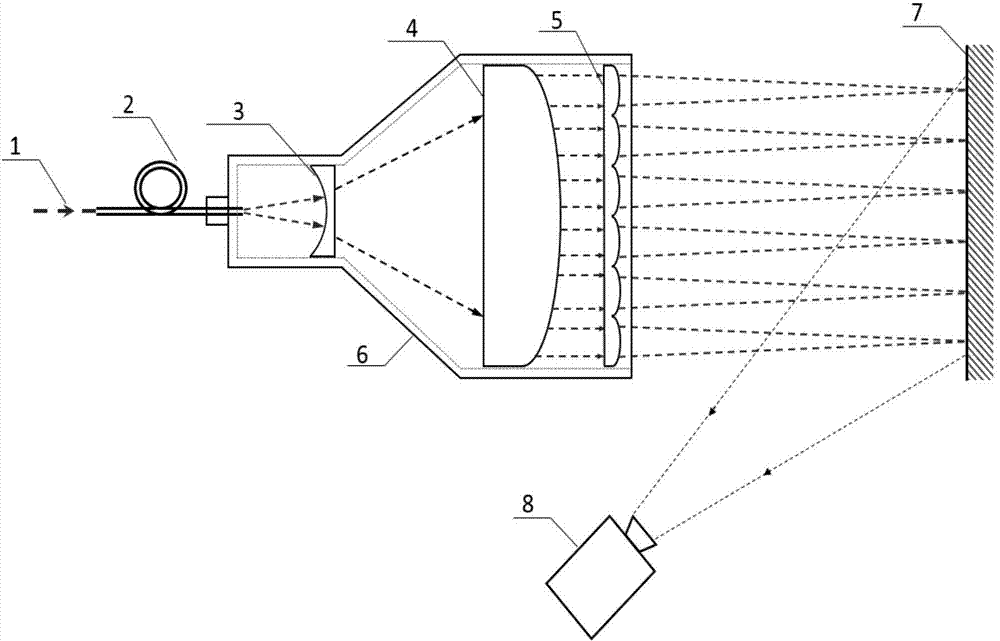

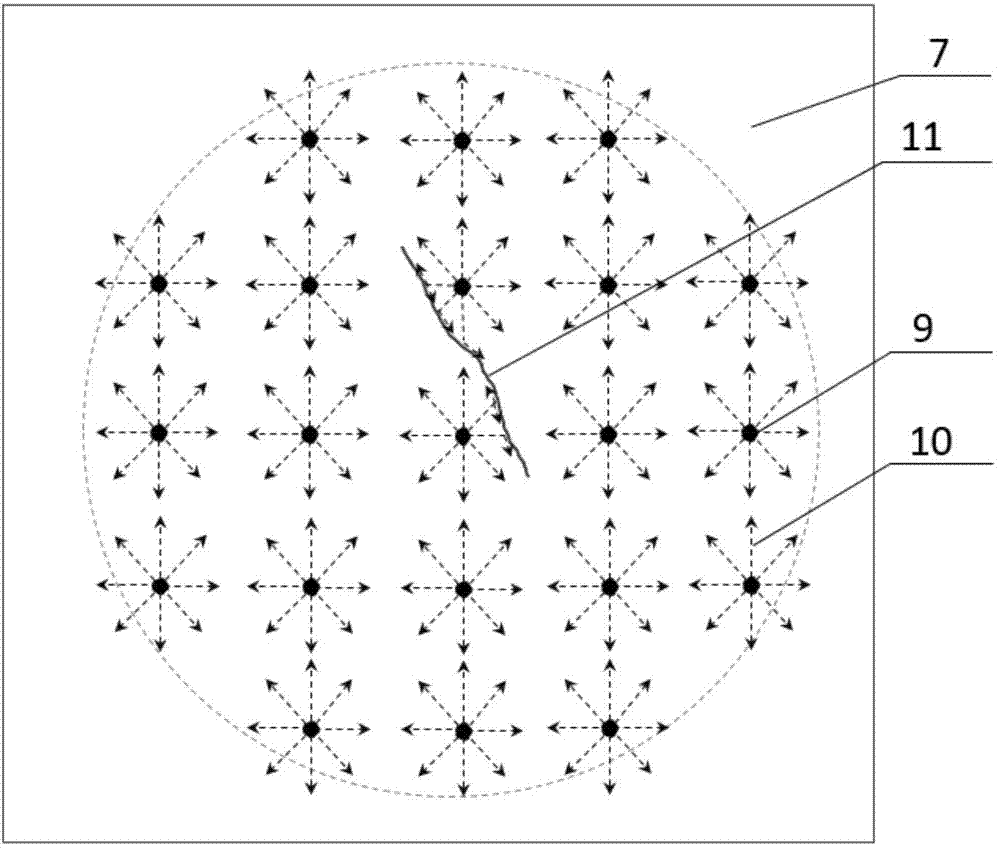

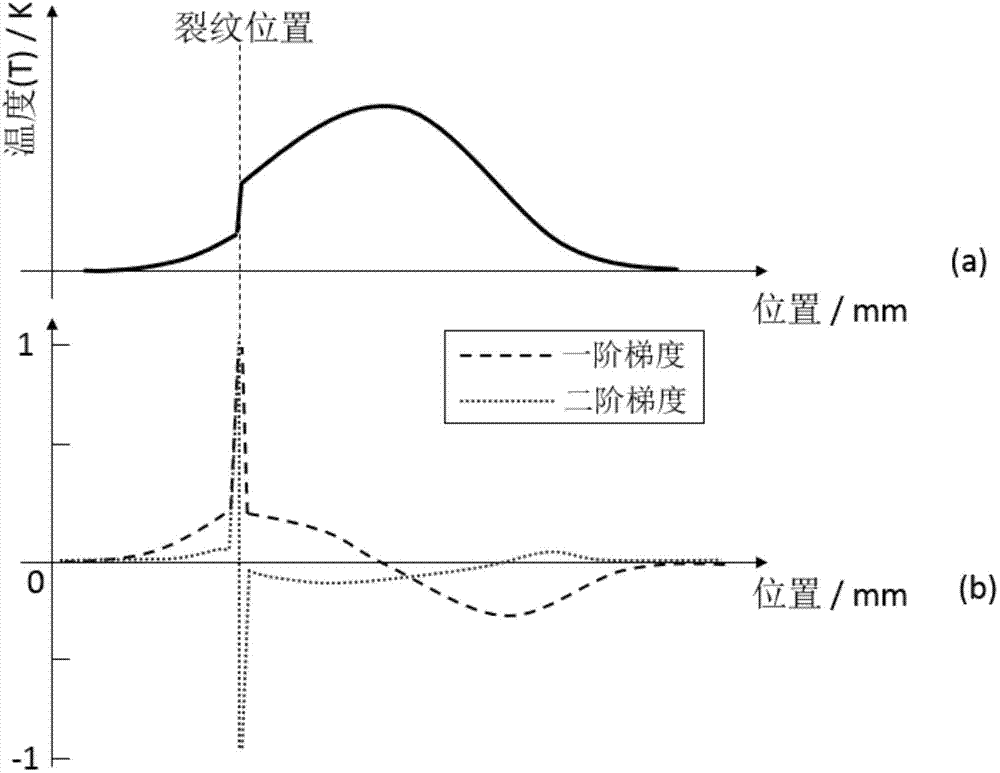

[0020] like figure 1 and figure 2 As shown, the measurement principle of the method of the present invention is: use a high-energy optical fiber to deliver the laser light to the vicinity of the detection object without moving the laser, and the laser beam after passing through the beam expander collimating lens and the focusing lens array is on the test piece 7 The surface and the area with a diameter of several centimeters form a plurality of uniformly distributed array laser point heat sources 9 with a radius of less than 1 millimeter. When the thermal energy 10 radiated from the laser point source diffuses to the vicinity of the crack 11, it will be hindered by it and cannot continue to propagate forward. It can only propagate along one side of the crack and diffuse from its two ends and bottom to the other side of the crack. Therefore, when the thermal energy diffuses to the vicinity of the crack for a period of time, not only will a large temperature difference (gradie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com