Laser cutting processing method and system of ceramic substrate

A ceramic substrate and laser cutting technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of slag on the cracked surface, inapplicability, and jagged edges, etc., and achieve the improvement of yield rate and excellent solution The effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

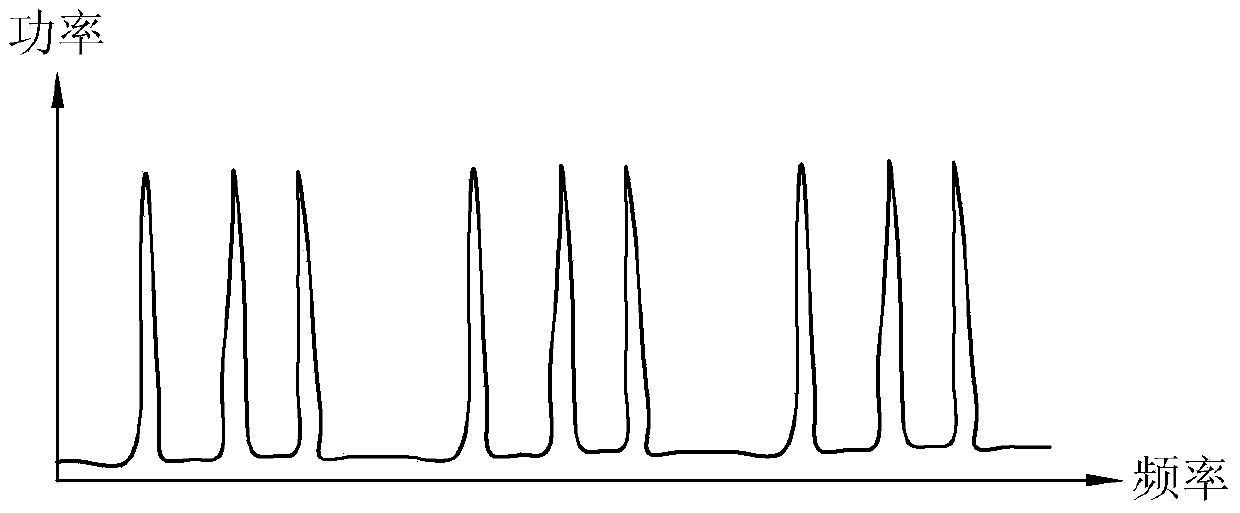

[0024] The embodiment of the present invention takes figure 1 The schematic diagram of laser frequency recombination is used to illustrate the specific implementation. Its features include the use of pulsed lasers. By recombining the laser frequency, multiple laser pulses fall on the same point of the workpiece to achieve dot marking or dotted line marking on the ceramic substrate. Separation is carried out in a split mode; using the process method of the present invention, adjusting the number of pulses in a single hole can control the variation of the hole depth; the power of the laser used to complete the dot marking or dotted line marking process does not need to be too high, because multiple pulses can The hole depth is increased to achieve the effect of high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com