Laser cleaning system for rubber module

A laser cleaning and rubber mold technology, applied in the field of laser cleaning, can solve the problems of inapplicability and laser power loss, and achieve the effects of easy operation, fast cleaning speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

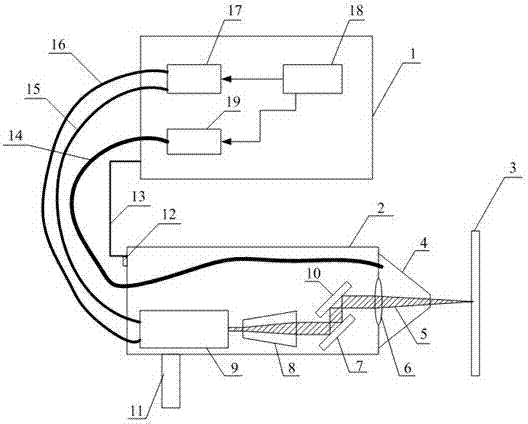

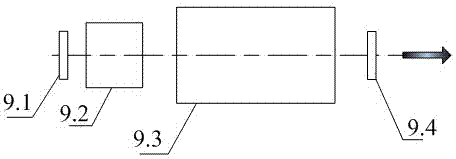

[0033] figure 1 It is a system configuration diagram of an embodiment of the present invention, which includes a laser cleaning head and a laser control system 18; the laser cleaning head includes a laser 9 and a beam expander 8, and the output light direction of the beam expander 8 is provided with a 45° total reflection mirror 7 , A scanning vibrating mirror 10 is provided on the reflected optical path of the 45° total reflection mirror 7, and a focusing lens 6 is arranged on the reflecting optical path of the scanning vibrating mirror 10, and the output end of the optical path of the focusing lens 6 outputs the laser beam 5 for cleaning the article 3.45 ° The total reflection mirror is placed at a 45° angle to the main optical path, and the scanning galvanometer is placed at a 45° angle to the main optical path. The laser cleaning head is arranged in the housing to form the cleaning processing head 2, the front end of the cleaning processing head 2 is provided with a protec...

Embodiment 2

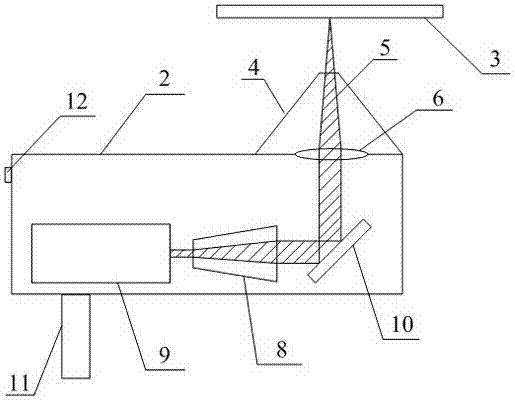

[0040] The structure and principle of the present embodiment are basically the same as the first embodiment, the difference is that the 45 ° total reflection mirror is removed in the laser cleaning head, and its structure is as follows figure 2 As shown, it includes a laser 9 and a beam expander 8 , a scanning vibrating mirror 10 is provided in the output light direction of the beam expanding mirror 8 , and a focusing lens 6 is provided on the reflected light path of the scanning vibrating mirror 10 . The scanning galvanometer 10 is placed at 45° to the main optical path to deflect the laser beam 5 by 90°. The protective cover 4 is installed on the side of the cleaning processing head 2 and is located in front of the focusing mirror 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com