Method and device for processing multi-head laser disordered and textured roller surface

A roll surface and processing equipment technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of strong reflection and different reflection effects of the plate surface, etc., achieve low production cost, high hardness, and increase the amount of passing steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

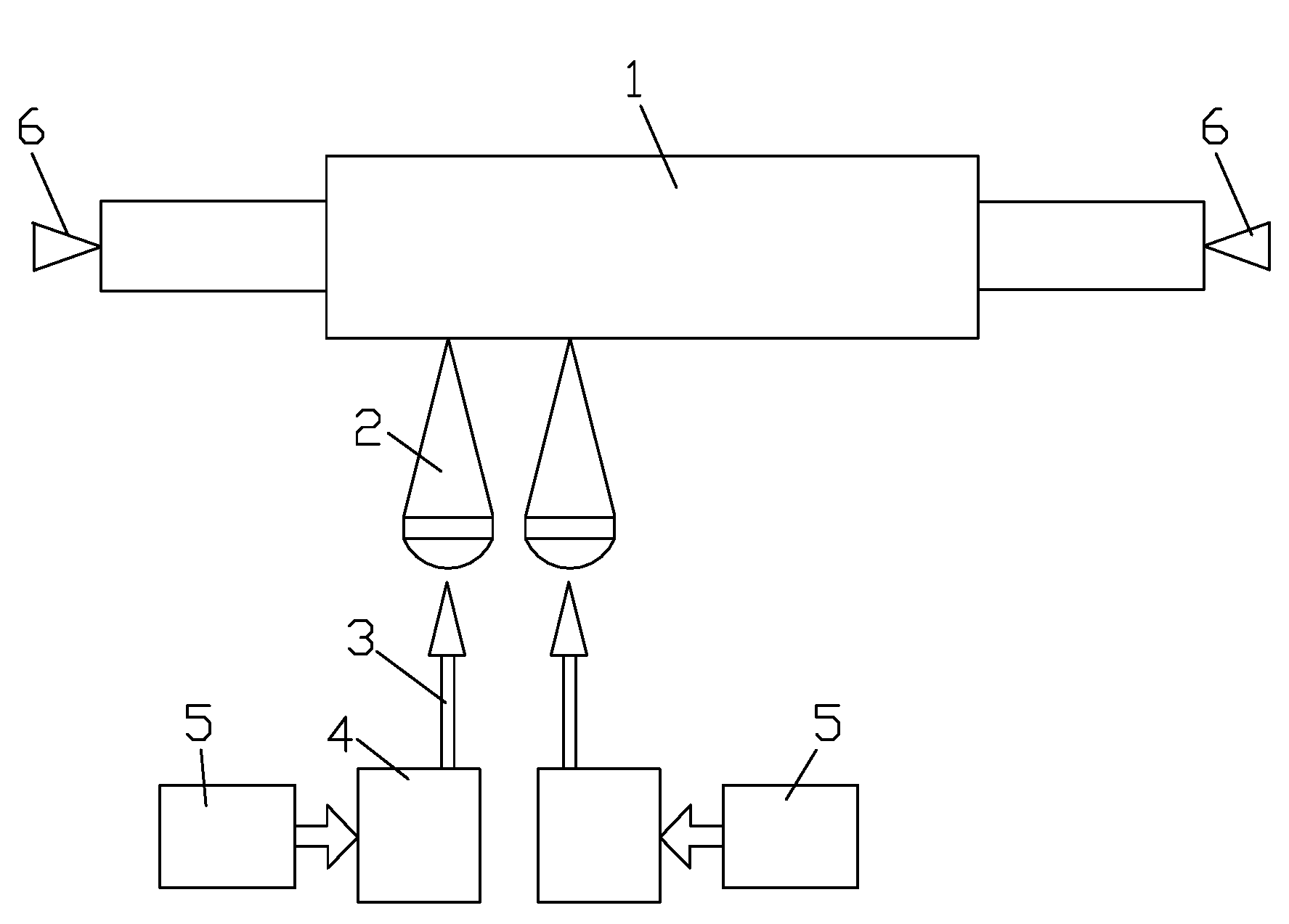

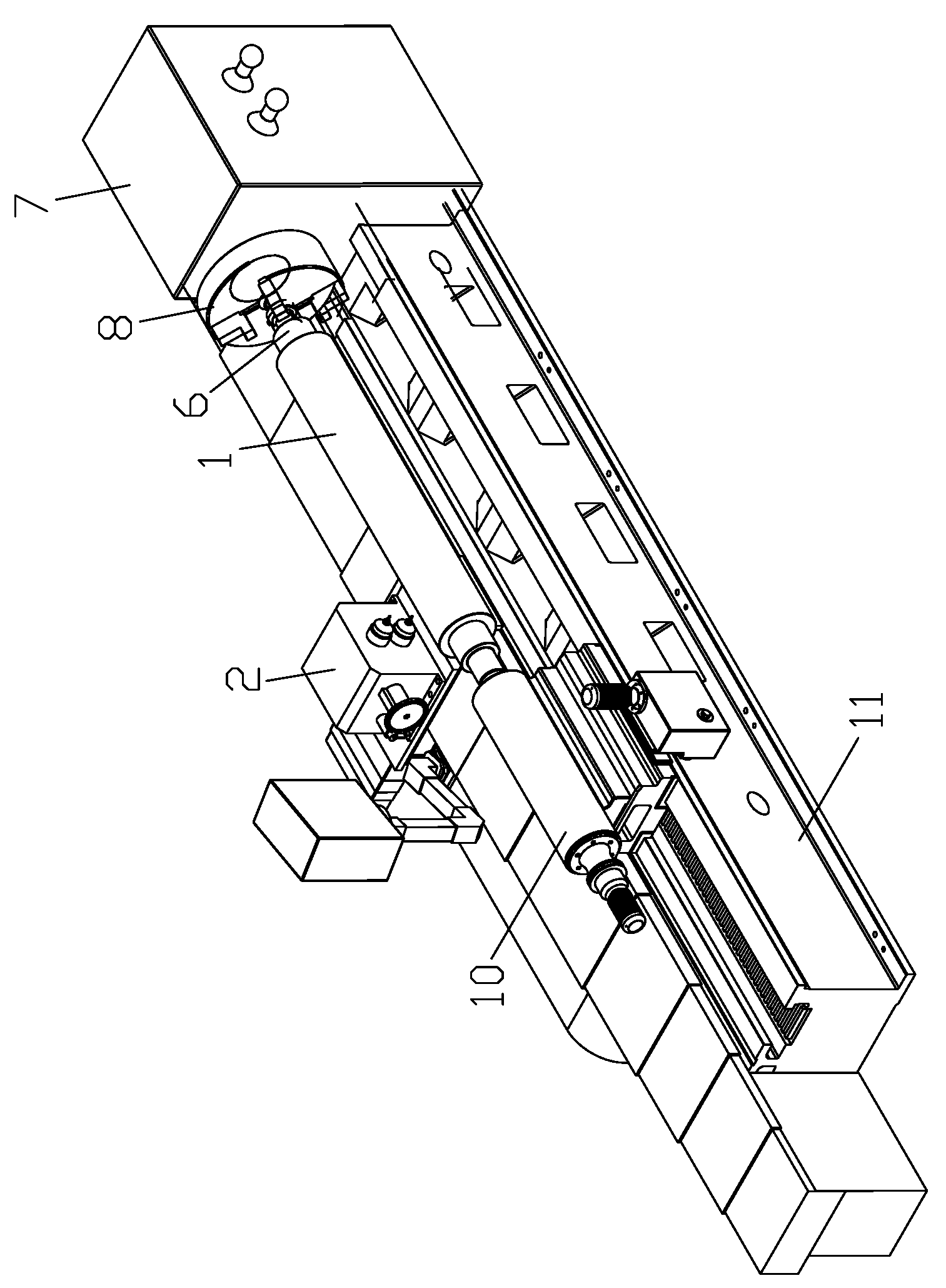

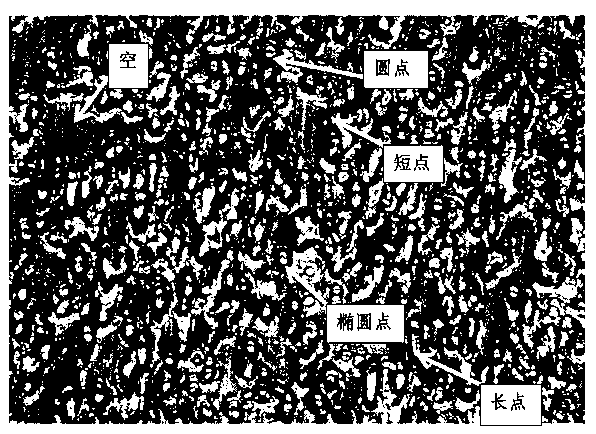

[0024] The invention relates to a method for processing the surface of a multi-head laser disordered roughening roll. Two random signal generators 5 are used to control two pulse lasers 4 to generate a disordered pulse laser beam 3. After focusing, two beams are processed on the surface of the roll 1. Helix without overlapping tracks, the distance between the two adjacent helixes is less than 150% of the laser spot diameter; the lead of the helix is equal to the distance between adjacent helixes multiplied by the number of helixes value. The pulse laser 4 randomly changes the duty ratio of the laser beam 3 by the random variable sent by the random signal generator 5; pulse frequency.

[0025] Two random signal generators 5 control the pulsed laser beams 3 of the two pulsed lasers 4, and the surface of the roll 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com