Method and device for continuously synthesizing diamond membrane by radiating carbon nanotube with strong laser

A technology for diamond thin film and synthesizing diamond, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of low synthesis efficiency, complicated equipment, difficult operation, etc., and achieve low equipment cost, uniform distribution, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

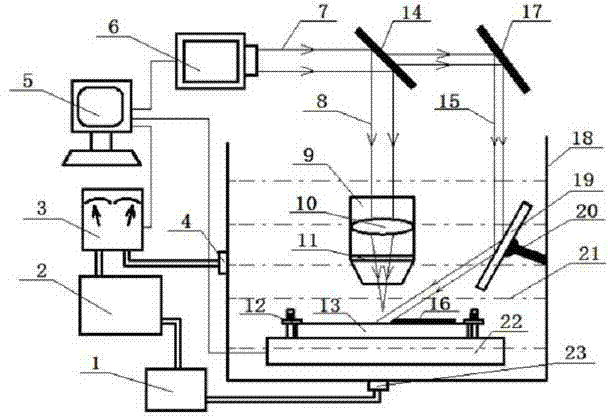

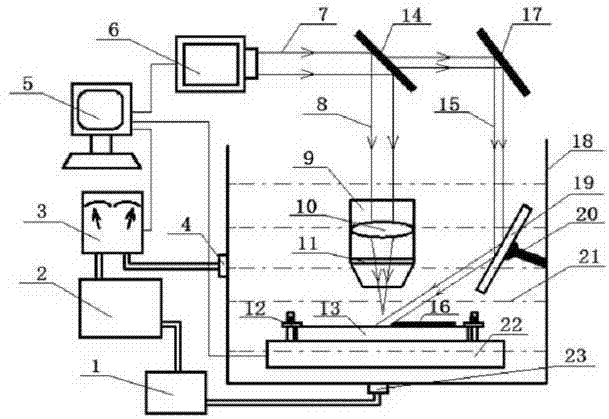

[0018] Polish the surface of the nickel-based alloy, then clean it with acetone and alcohol, and fix it on the workbench 22 with a clamp 12, then pour an appropriate amount of water into the reaction vessel 18, suspend the carbon nanotube powder in the water, and use electromagnetic vibration Stir to evenly disperse. Turn on the power supply of the electric pump 1 to circulate the aqueous solution, and adjust the flow control device 3 so that the circulation rate of the aqueous solution is 0.45ml / s. Turn on the high-power pulsed laser device 6, set the parameters by the computer 5, the pulse width is 10ns~20ns, the pulse frequency is 20Hz, and the power density is 10 8 W / cm 2 . The laser light 7 emitted by the high-power pulsed laser device 6 is reflected and split by the spectroscopic mirror, and the laser beam G18 is directly reflected and passed through the laser processing head 9 and focused at a distance of 3 mm directly above the surface of the nickel-based alloy. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com