Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

A coaxial powder feeding and composite processing technology, applied in the field of additive manufacturing, can solve the problems of lack of fusion, high core temperature, under-melting of the melt channel, etc., to improve the internal stress state, improve mechanical properties, and avoid deformation and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiment:

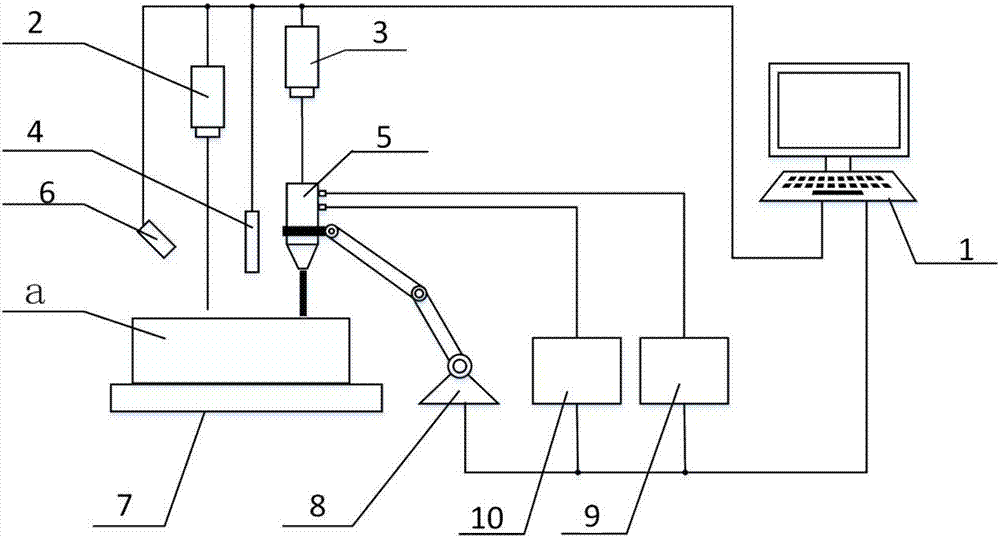

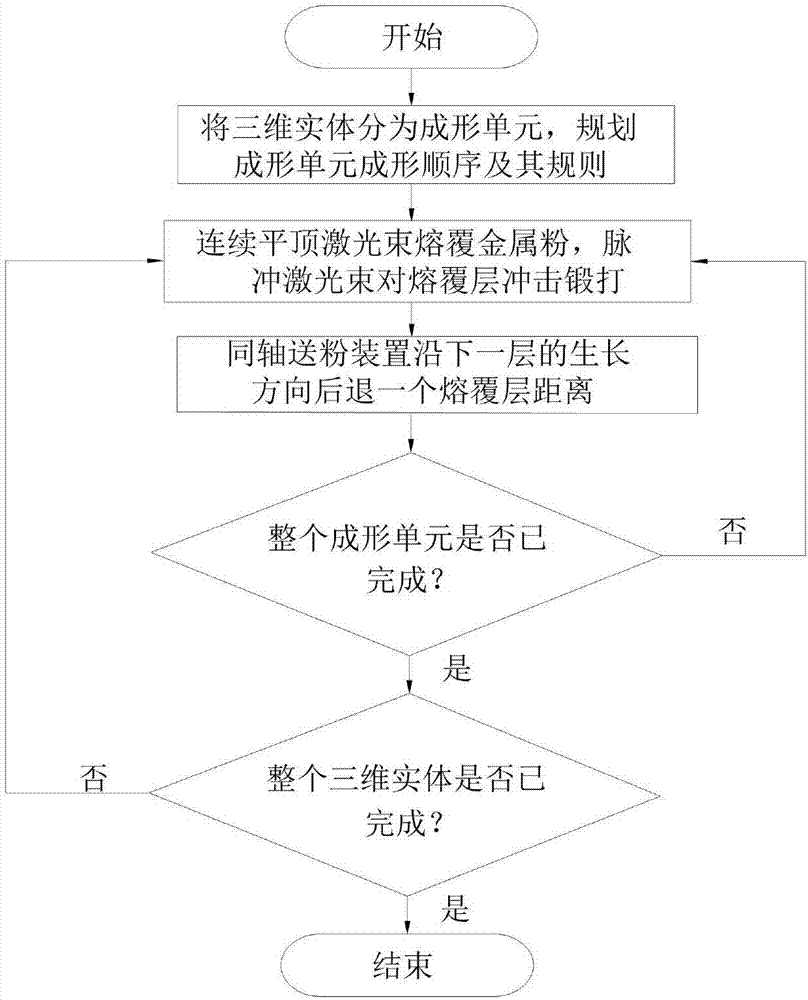

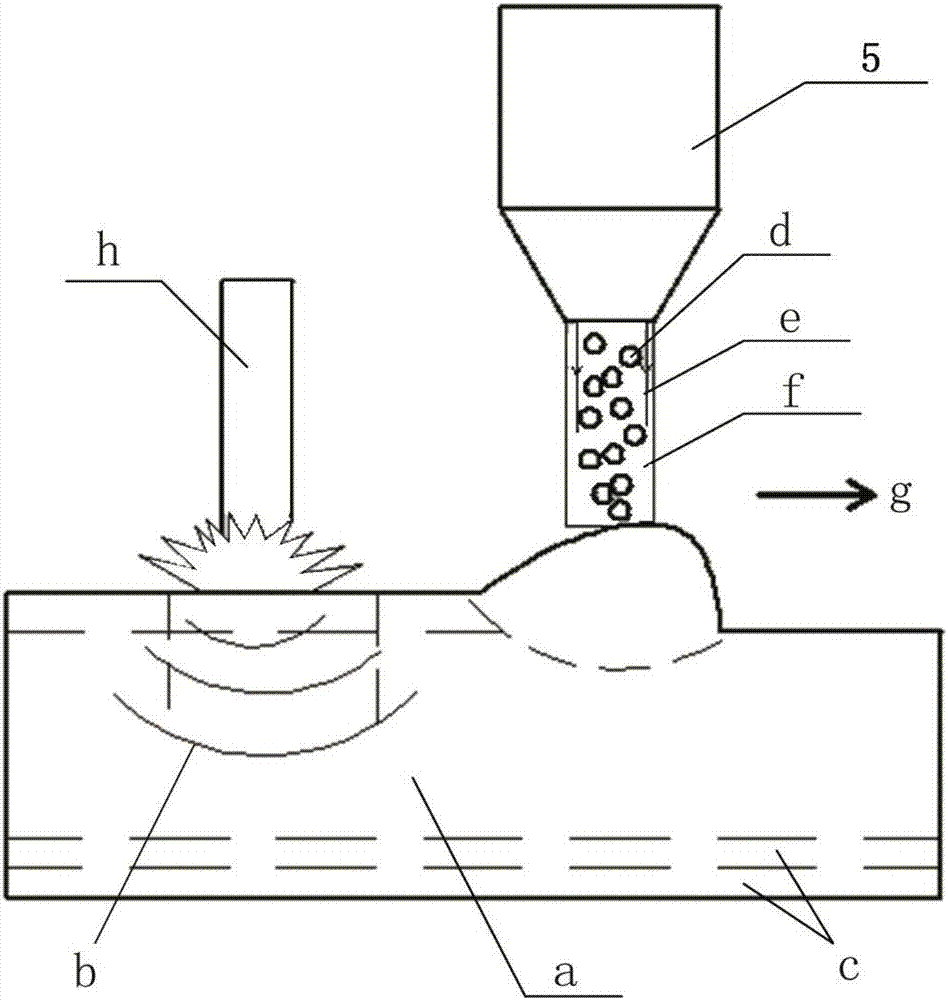

[0023] See attached Figure 1-3 As shown, a laser shock forging compound processing forming device with coaxial coaxial powder feeding in the light described in this embodiment includes a main control machine 1, a pulse laser 2, a continuous laser 3, a temperature sensor 4, and a coaxial powder feeding device 5. Visual tracking system 6, workbench 7 for placing cladding formed parts a, mechanical arm 8, metal powder container 9 and gas container 10; among them, pulse laser 2, continuous laser 3, temperature sensor 4, The visual tracking system 6 is placed above the workbench 7; the mechanical arm 8 is fixed on one side of the workbench 7 to clamp the coaxial powder feeding device 5, so that the coaxial powder feeding device 5 is located between the continuous laser 3 and the workbench 7 And the coaxial powder feeding device 5 is coaxial with the continuous laser 3; the coax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com