UV (Ultraviolet)-thermoplastic resin composite laser aluminum-plated coating composition

A technology of thermoplastic resin and laser aluminum plating, applied in the direction of epoxy resin coating, polyester coating, polyurea/polyurethane coating, etc., can solve the problem of not meeting the production requirements, affecting the effect of laser pattern, and the laser pattern is not heat-resistant and easy to deform and other problems, to achieve the effect of not easy to deform, reduce the influence of thermal deformation, and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

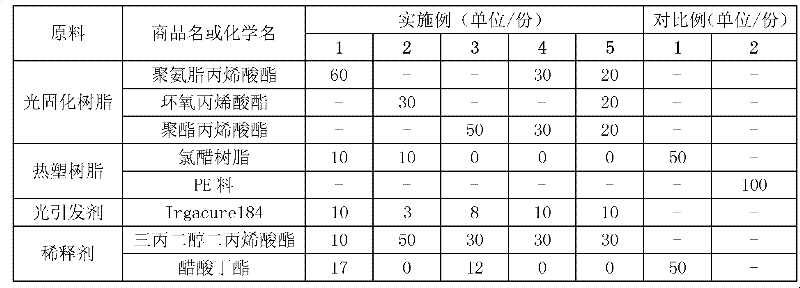

[0044] Embodiments 1 to 5 respectively provide UV-thermoplastic resin composite laser aluminized coating compositions, and the corresponding raw material components and parts by weight of each composition are shown in Table 1;

[0045] The raw material components corresponding to each embodiment were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding UV-thermoplastic resin composite laser aluminized coating combination.

[0046] Table 1 raw material components and parts by weight

[0047]

Embodiment 6

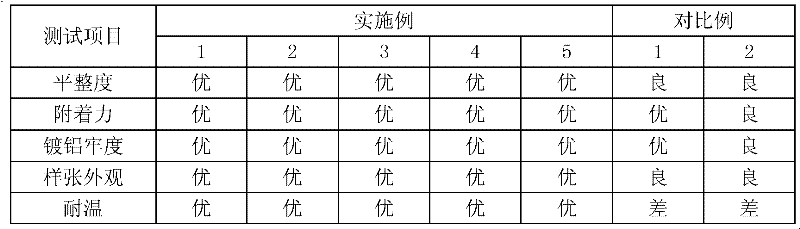

[0048] Embodiment 6, performance testing

[0049] Performance tests were performed on the coating compositions prepared in Examples 1-5 and Comparative Example 1 to measure the coating's smoothness, adhesion, aluminizing fastness, sample appearance, and temperature resistance performance parameters.

[0050] The specific performance testing items and corresponding methods are as follows:

[0051] 1. Flatness

[0052] The paint is coated on the pretreated PET film by scraping method, and the coating flatness of the proof is visually inspected.

[0053] Test method: Visually observe the appearance of the test sample.

[0054] Evaluation method: the surface of the sample sheet is smooth and flat as excellent, and the surface is uneven and wrinkled as poor.

[0055] 2. Adhesion

[0056] The paint is coated on the pretreated PET film by scraping method, and the pattern of the embossed plate is pressed on the coating when curing. The adhesive tape method was used to test the ...

Embodiment 7~11

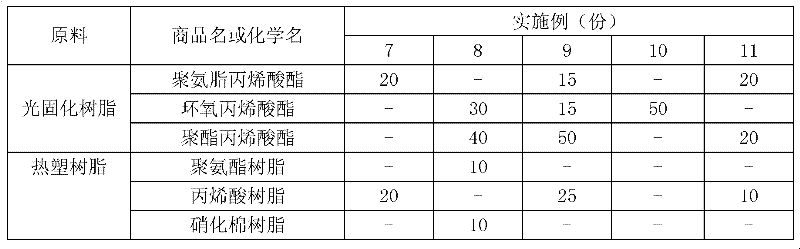

[0073] Embodiments 7 to 11 respectively provide UV-thermoplastic resin composite laser aluminized coating compositions, and the corresponding raw material components and parts by weight are shown in Table 3; Mix several times, disperse at a medium speed for 2 hours, and filter to obtain the corresponding UV-thermoplastic resin composite laser aluminized coating composition.

[0074] The coating compositions prepared in Examples 7 to 11 all have excellent flatness, adhesion, fastness to aluminum plating, appearance of proof sheets and temperature resistance. Moreover, because the film is formed by photocuring, the molding process can be carried out simultaneously by molding and curing. In this way, because the coating is still liquid during molding, deep grooves can be molded, and the formed laser pattern has a strong three-dimensional effect. In addition, the coating adopts photocuring and crosslinking to form a film, and the coating has good heat resistance, and the laser pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com