Laser projector and depth camera thereof

A laser projector and light-emitting element technology, applied in the optical field, can solve the problems of reducing the irrelevance of laser patterns, and achieve the effects of improving the irrelevance, speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

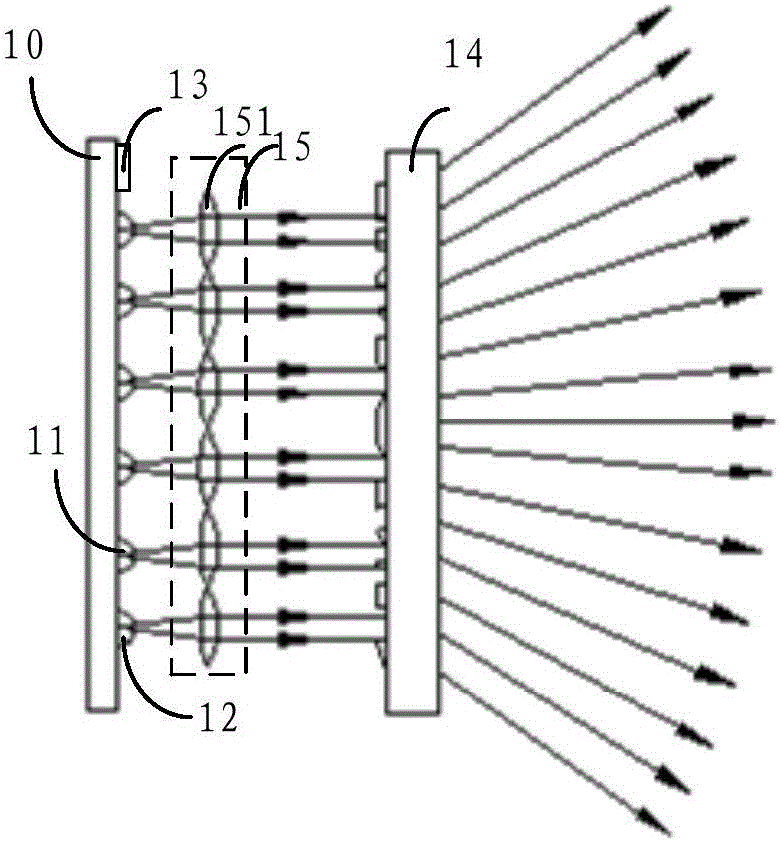

[0030] refer to figure 1 , figure 1 It is a structural schematic diagram of an embodiment of the laser projector of the present invention.

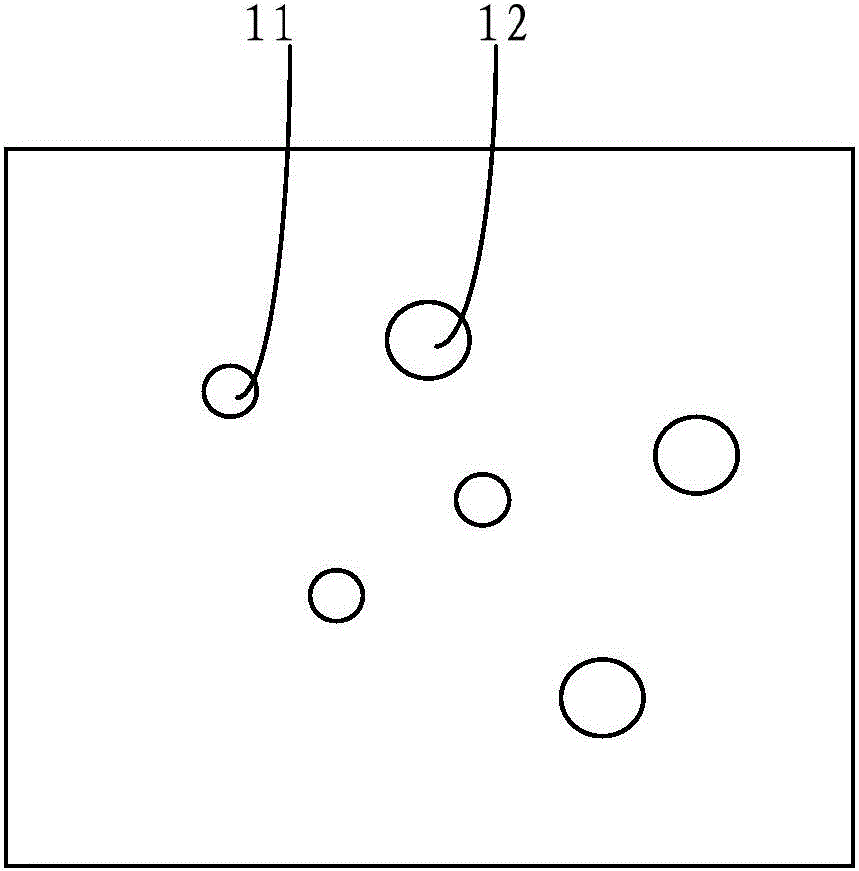

[0031] The laser projector in this embodiment includes a substrate 10, at least two light emitting elements 11 and 12, a controller 13 and a diffractive optical element 14;

[0032] Wherein, the diffractive optical element 14 is arranged at a position separated from the substrate 10 by a first distance; at least two light emitting elements 11, 12 are fixed on the side of the substrate 10 facing the diffractive optical element 14;

[0033] At least two light-emitting elements 11, 12 emit laser light under the control of the controller 13, and at least two light-emitting elements 11, 12 have at least two different light-emitting areas; the diffractive optical element 14 is used to combine at least two light-emitting elements 11, 12 The laser beam emitted by 12 expands and emits a laser pattern into the space.

[0034] The laser projector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com