Three-dimensional greening heat-preserving module

A thermal insulation module and three-dimensional greening technology, which is applied in thermal insulation, agricultural gas emission reduction, botany equipment and methods, etc., can solve the problems of increased irrigation system leakage, water easily splashed on the wall, and irrigation system leakage, etc., to achieve effective It is beneficial to plant growth and survival, beneficial to plant growth, and the effect of simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

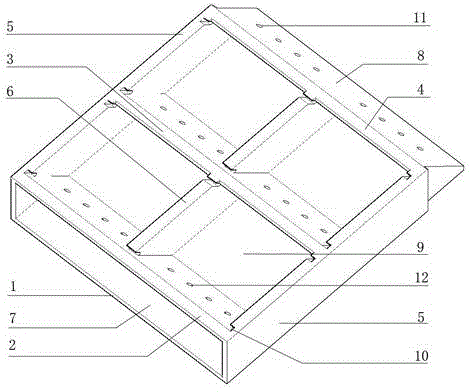

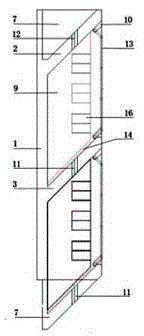

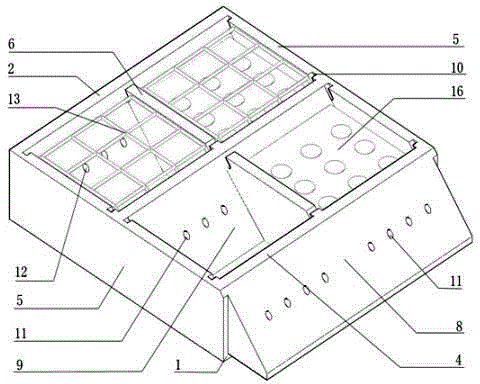

[0027] refer to Figure 1 to Figure 5 , the three-dimensional greening and thermal insulation module includes a module body, the module body is composed of a bottom plate 1, an upper frame 2, a lower frame 4, a side frame 5, a transverse partition 3, and a longitudinal partition 6. It is molded by thermosetting modified polystyrene (TPS); the side frame 5 is vertically arranged on both sides of the upper surface of the bottom plate 1; the upper frame 2 is arranged on the upper surface of the bottom plate 1 at an angle of 45° The upper end of the upper frame, the upper frame 2, the side frame 5, and the bottom plate 1 form a wedge-shaped socket 7; the lower frame 4 and the bottom plate 1 are arranged at the lower end of the upper surface of the bottom plate 1 at an angle of 45 degrees, and the lower frame 4 and the side The frame 5 and the bottom plate 1 form a wedge-shaped socket 8, the width of which is equal to or slightly smaller than the inner width of the socket 7; the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com