Pipeline penetrating floor fireproof structure

A technology for floors and pipes, applied in the field of fireproof structures where pipes pass through floors, can solve problems such as destructive disassembly, leaving fire hazards, and failing to reach the fire resistance limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

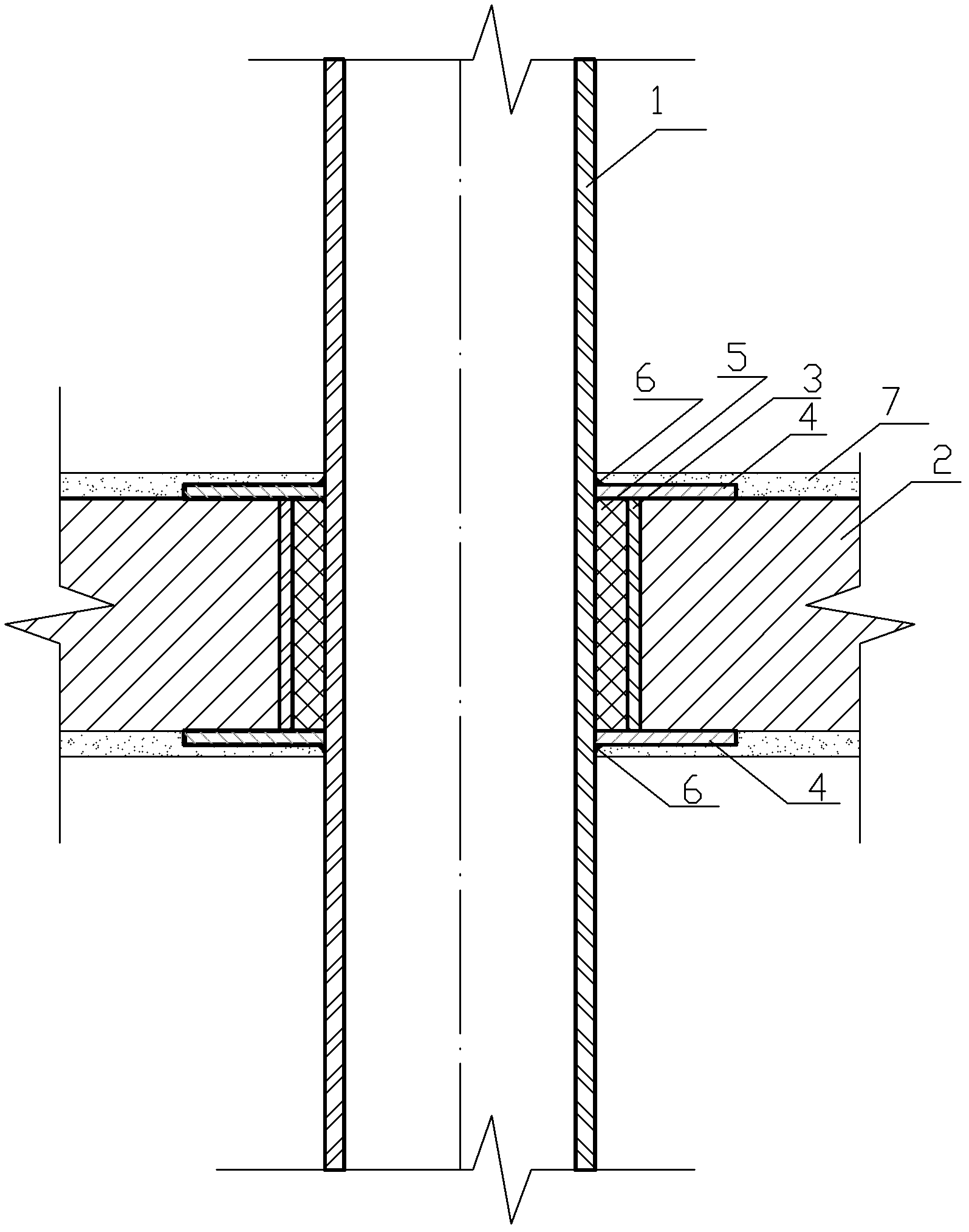

[0009] As shown in Figure 1, this kind of fire-proof structure for pipelines passing through the floor requires a hole 50 mm larger than the outer diameter of the pipeline to be reserved on the floor, and a casing is embedded in the hole. The height of the casing is the same as the thickness of the floor. The floor is equipped with 10 thick fireproof gypsum boards, which are fixed and connected with nails. The length of the fireproof gypsum boards exceeds the casing by 150 mm, and the inner diameter of the casing, the outer diameter of the pipe and the fireproof gypsum board are sealed and compacted with foam glass. Apply sealant where the fireproof plasterboard meets the pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com