Combined vertical wiring rubber-lined roller device and rubber-lining method

A rubber roller and rubber lining technology is applied in the field of combined vertical wiring rubber lining device and rubber lining. The effect of good lining adhesion, high work efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

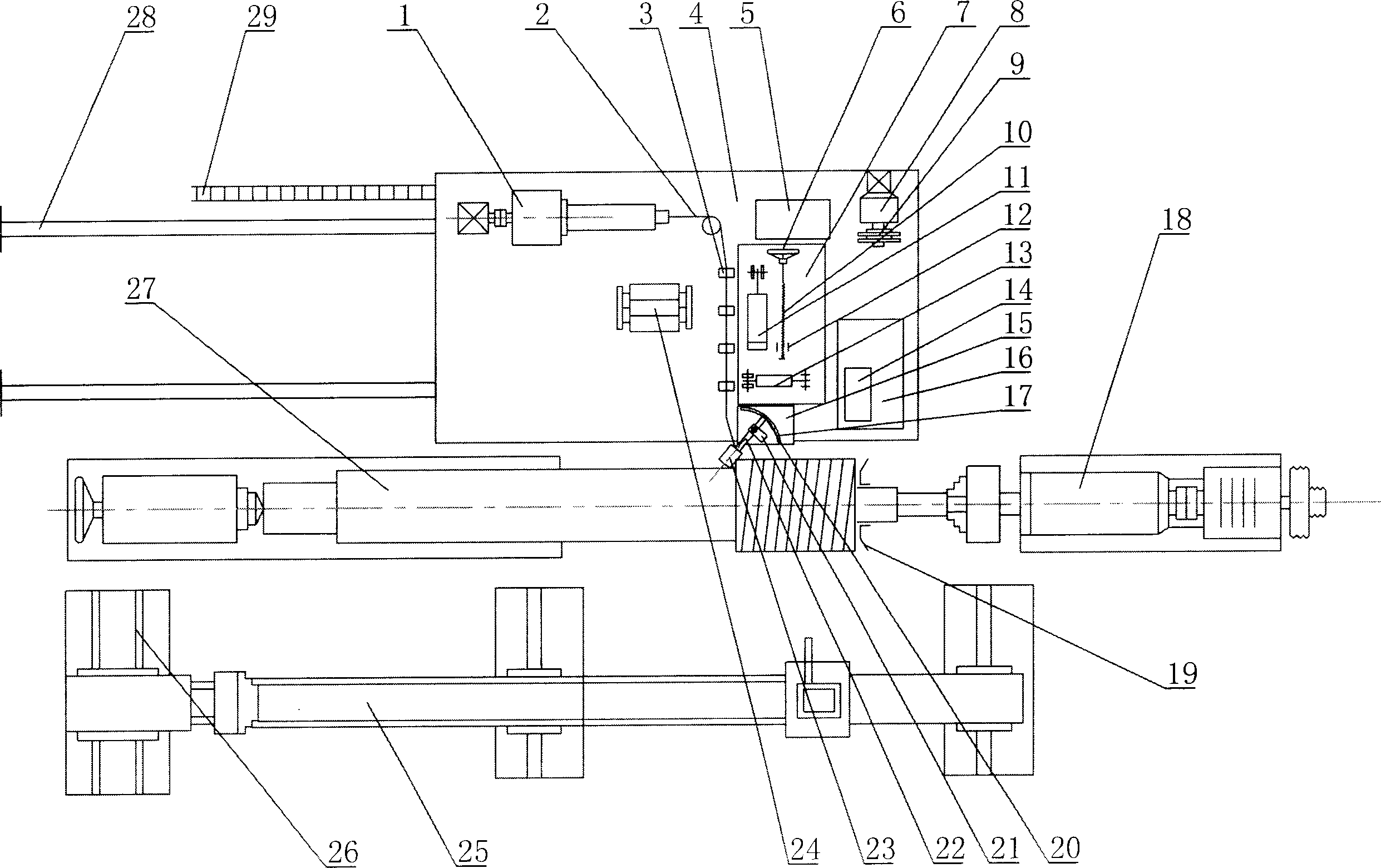

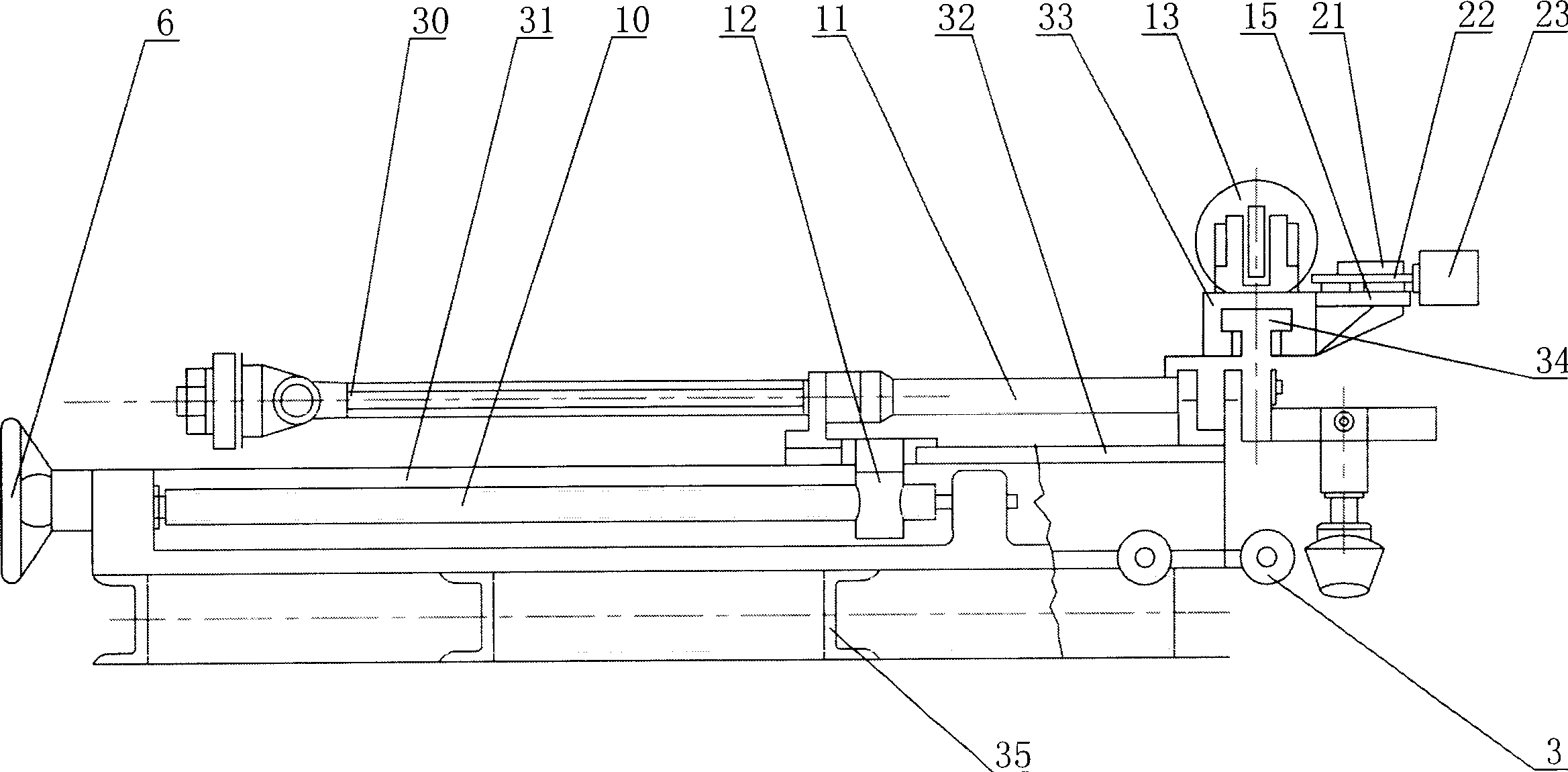

[0024] Such as figure 1 , figure 2 As shown, the combined vertical wiring rubber roller device of the present invention includes a main operating table 5, a rubber strip extruder 1, a rubber strip support roller 3, a backing roller rotary mechanism 18, a rubber roller car grinding machine 25, a rubber roller Core 27, roller core end baffle 19, water cloth strip binding and dismantling mechanism 24, rubber roller core 27 is installed and stuck between the backing roller slewing mechanism 18, headstock chuck and tailstock thimble, roller core end baffle 19 At the starting lining end of the rubber roller core 27, the characteristics are: the rubber strip extruder 1, the rubber strip support roller 2, the pressure roller pressing mechanism 7, the transmission reducer 8, the transmission sprocket chain 9, the reversing valve Group 14, pressure roller with electric pump oil ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com