Metal-plate curtain wall structure

A metal plate and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of contaminating the board surface, affecting the appearance of the curtain wall, time-consuming and laborious installation, etc., and achieving the effect of convenient installation, beautiful appearance and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

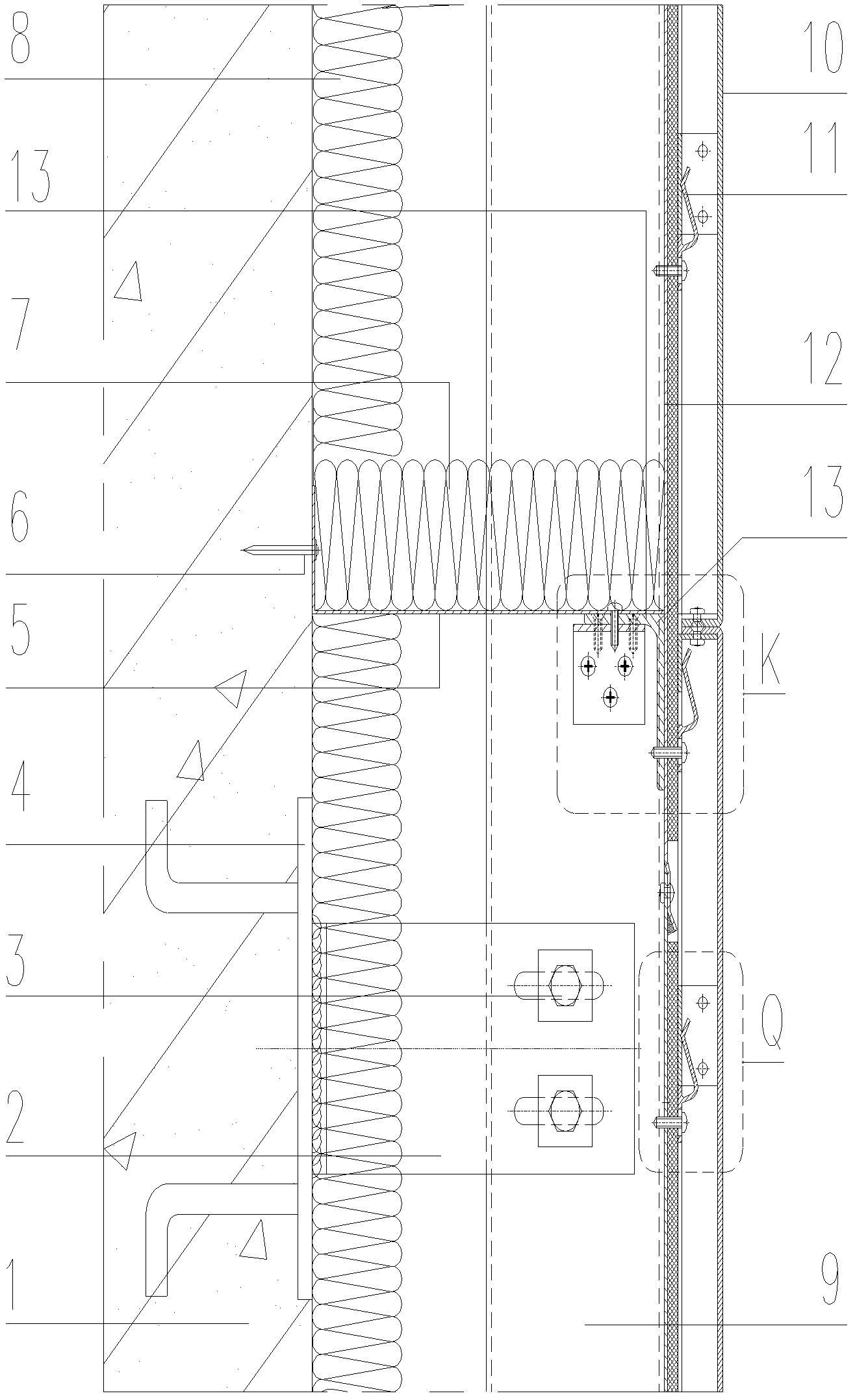

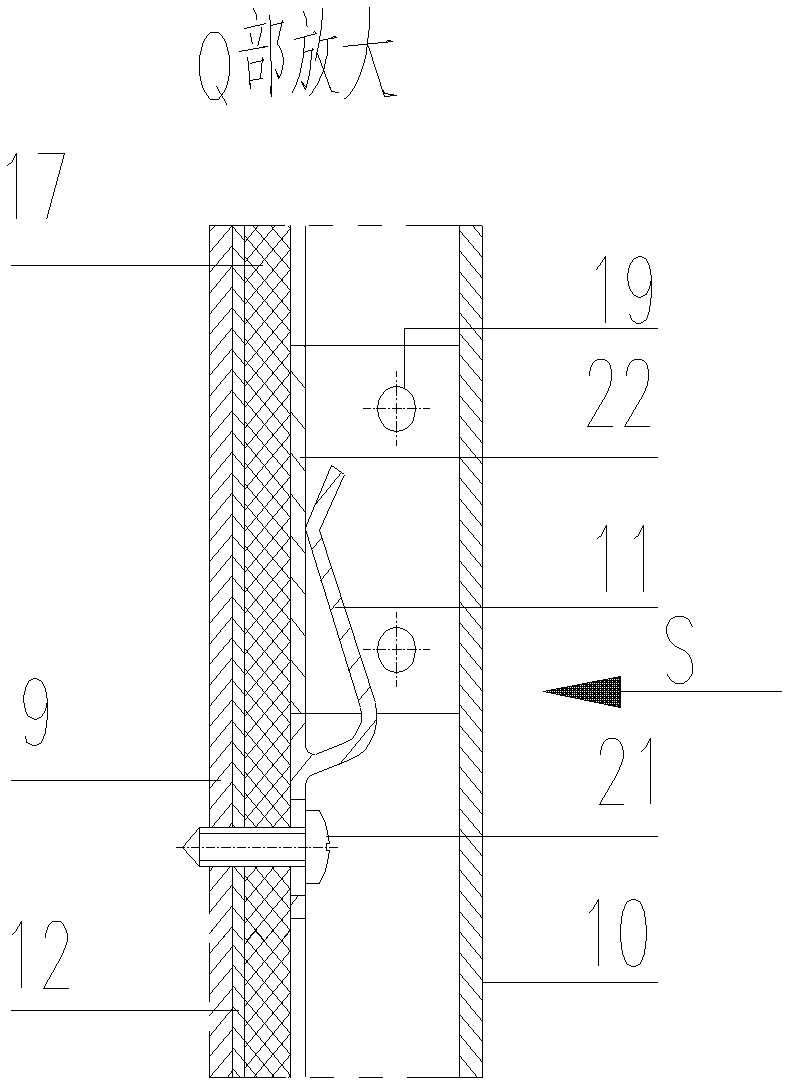

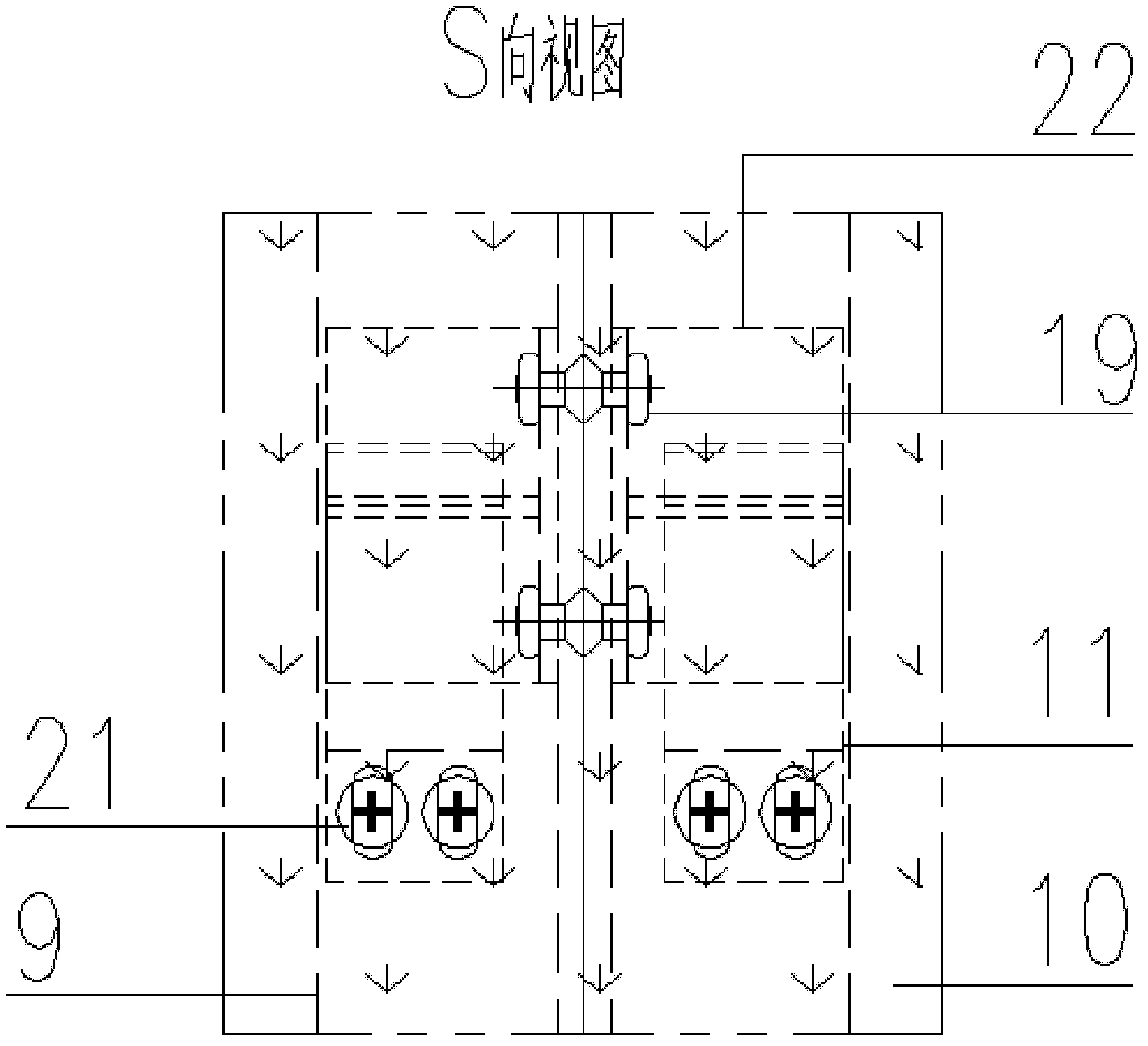

[0016] combine Figure 1 to Figure 5 , the metal plate curtain wall structure of the present invention includes a vertical keel 9, a beam 13 and a metal plate 10; the adapter 2 is welded on the embedded part 4 of the building main body 1; the front end of the adapter has an oblong hole (for adjusting the front and rear of the vertical keel) position size), the vertical keel 9 is fixed into one by the bolt assembly 3; the beam 13 is fixed on the vertical keel by the angle plate 14, the angle plate fixing screw 15 and the screw 16; there is a horizontal steel plate 5 between each layer, one side is The nails 6 are fixed on the main body of the building, and the other side is fixed on the beam; the horizontal steel plate is provided with fire-resistant rock wool 7, which is used for fire prevention and smoke prevention, and the thermal insulation rock wool 8 is installed on the main wall of the building for heat preservation, energy saving and noise reduction; The outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com