Pipe joint connected with pipe

A pipe connection and pipe joint technology, applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing element, etc., can solve the problems of seal failure, pipe damage, etc., to reduce damage, leave no gap, and ensure close contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

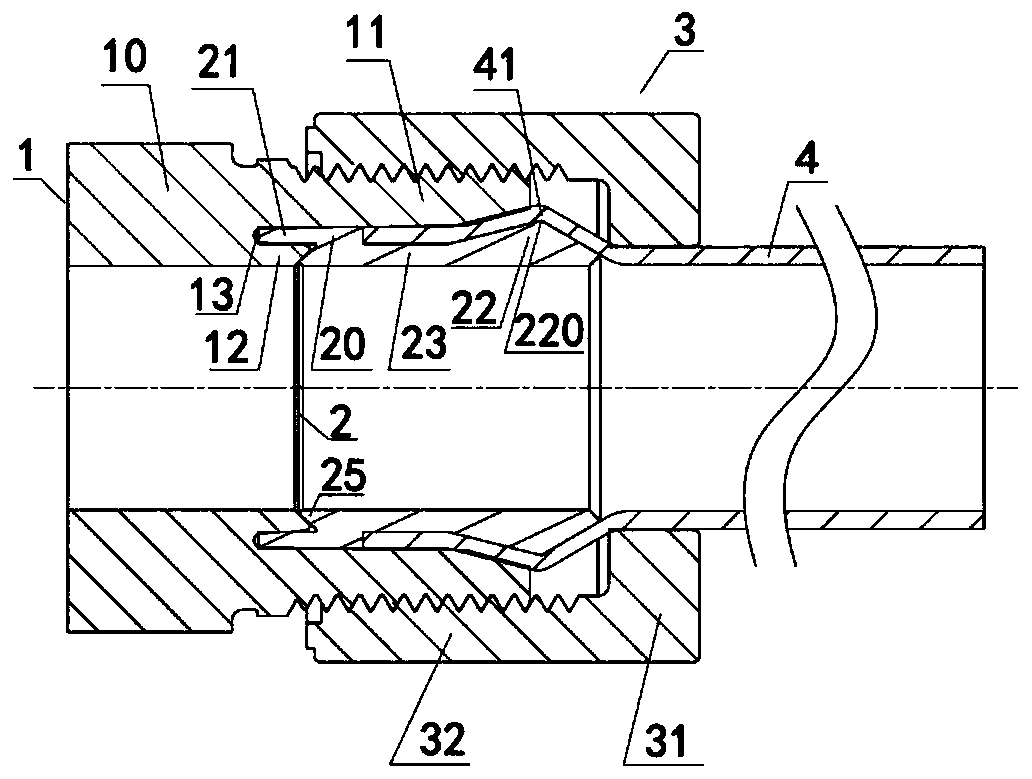

[0041] Such as Figure 3-4 As shown, the fitting includes:

[0042] The joint main body 1 has a coaxially arranged main body cylinder part 10, an outer cylinder part 11 and an inner cylinder part 12. The outer cylinder part 11 and the inner cylinder part 12 protrude in the same direction from the main body cylinder part 10, and the inner cylinder part 12 is arranged In the inner side of the outer tube part 11, the length of the outer tube part 11 protruding from the main body tube part 10 is greater than the length of the inner tube part 12 protruding from the main body tube part 10, and the body tube part 10, the outer tube part 11 and the inner tube part 12 surrounds and forms a groove portion 13, and the opening direction of the groove portion 13 is the same as the protruding direction of the outer cylinder portion 11 and the inner cylinder portion 12.

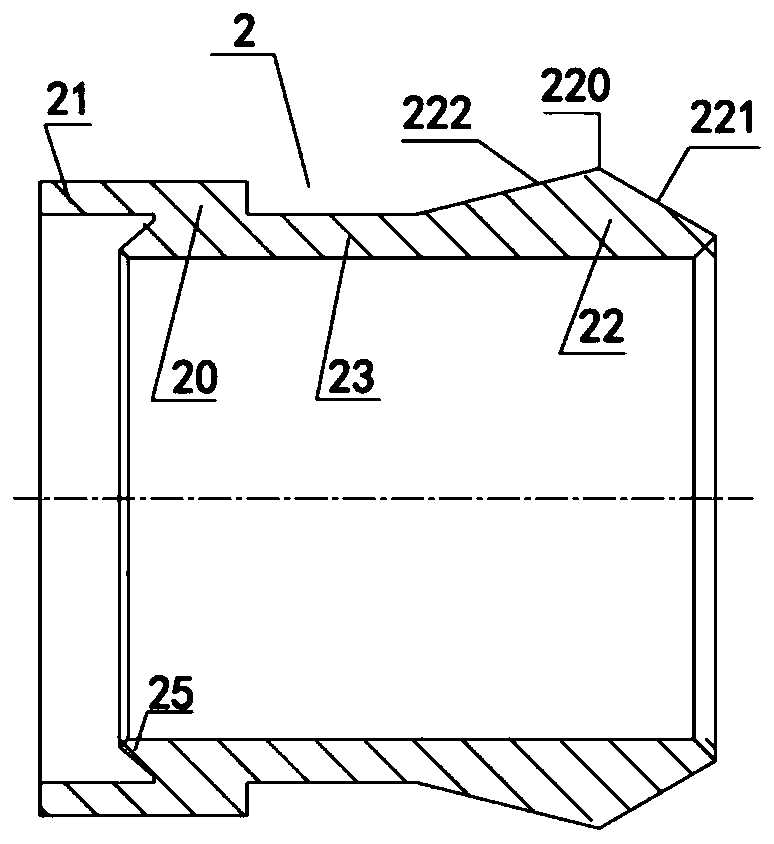

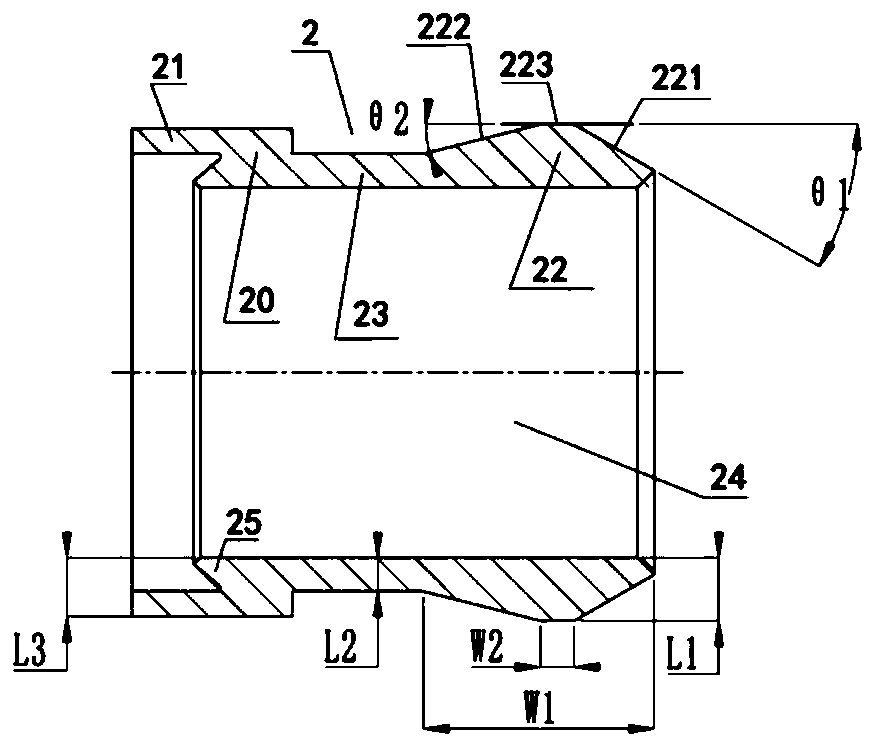

[0043] The inner ring 2 has a cylindrical insertion portion 21, a cylindrical fitting portion 20, a cylindrical connecti...

Embodiment 2

[0070] as attached Figure 6 As shown, in another structure of the inner ring 2, the outer surface of the transition section 223 of the protrusion 22 is a spherical surface, that is, the conical surface 221 with an enlarged diameter and the conical surface 222 with a reduced diameter are connected through the spherical surface transition. The connection is smooth, the spherical surface is in closer contact with the inner wall of the pipe 4, and the sealing effect is better, and the deformation of the pipe 4 is gradual, which can reduce the bending curvature of the pipe 4 and reduce the damage to the pipe 4.

[0071] The included angle θ3 between the tangent at any point on the spherical surface and the axial direction of the inner ring 2 is 0°-35°, and the spherical surface is tangentially connected with the tapered surface 221 with an enlarged diameter and the tapered surface 222 with a reduced diameter at the intersection point. At the point of intersection with the tapered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com