High-pressure cleaning equipment capable of saving water and energy and fusing air and water

A high-pressure cleaning and water-gas technology, which is applied to vehicle cleaning equipment, vehicle cleaning, cleaning methods and appliances, etc., can solve problems such as impossible energy saving, potential safety hazards, power consumption loss, etc., and achieves improved use efficiency and simple structure , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

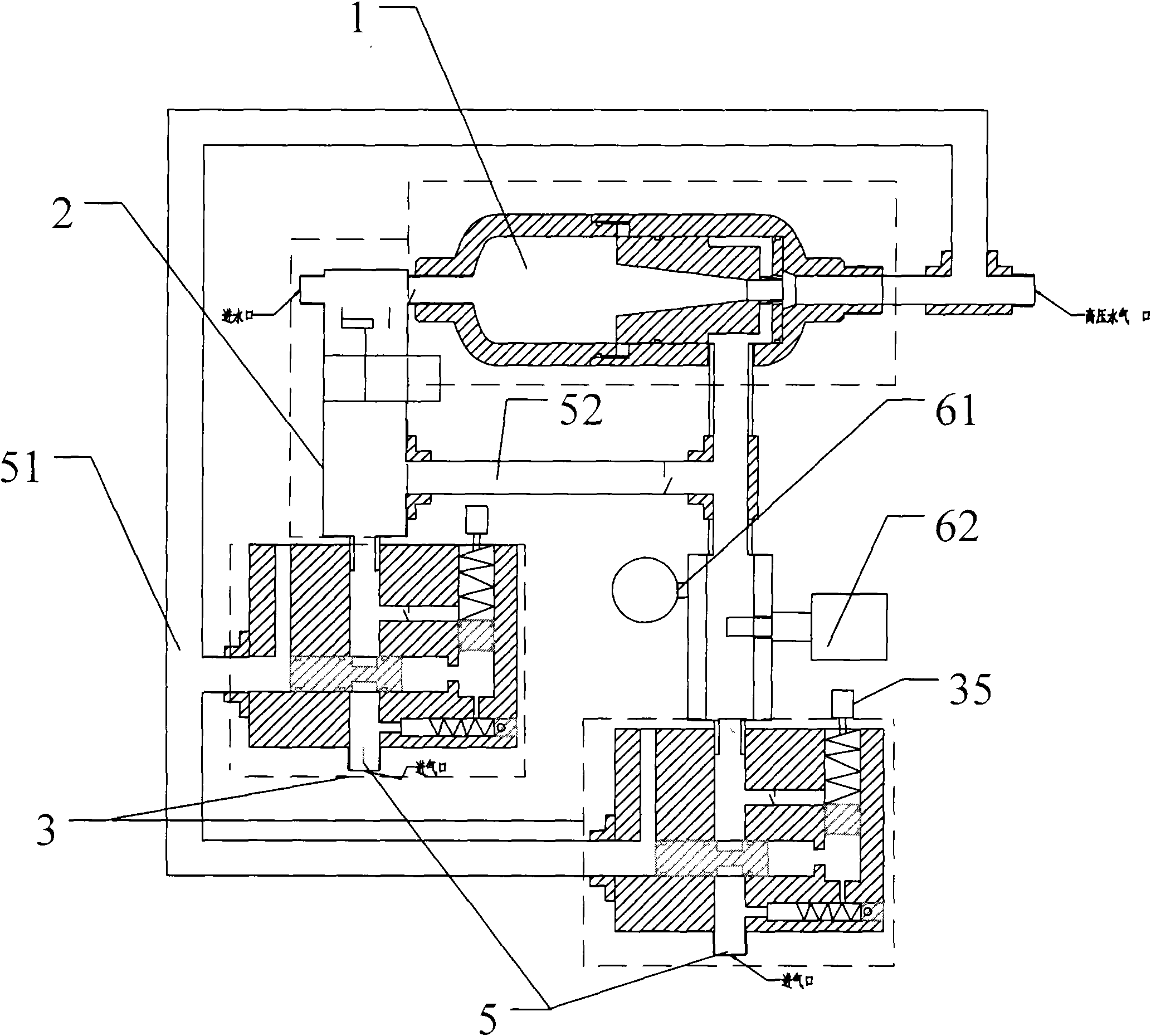

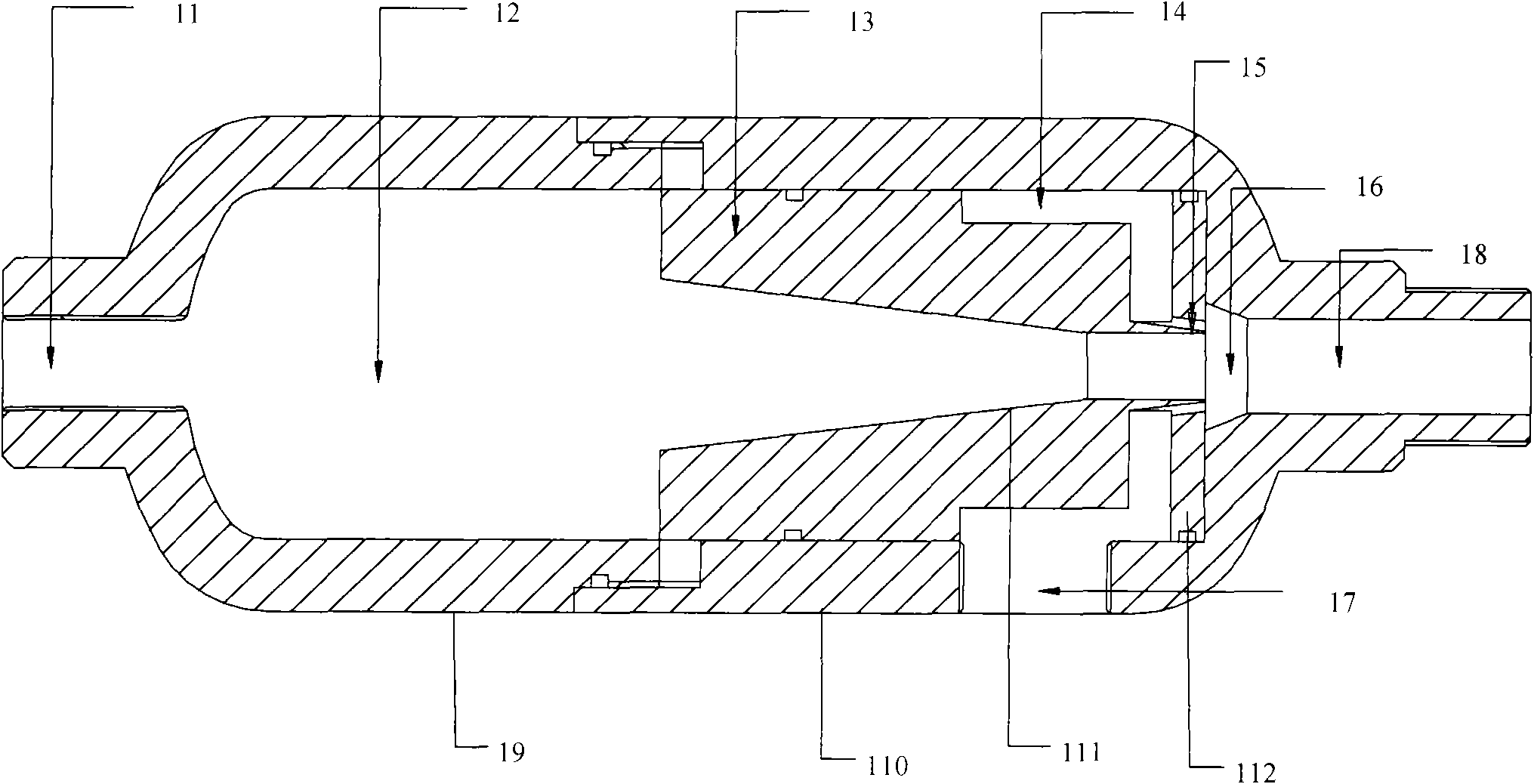

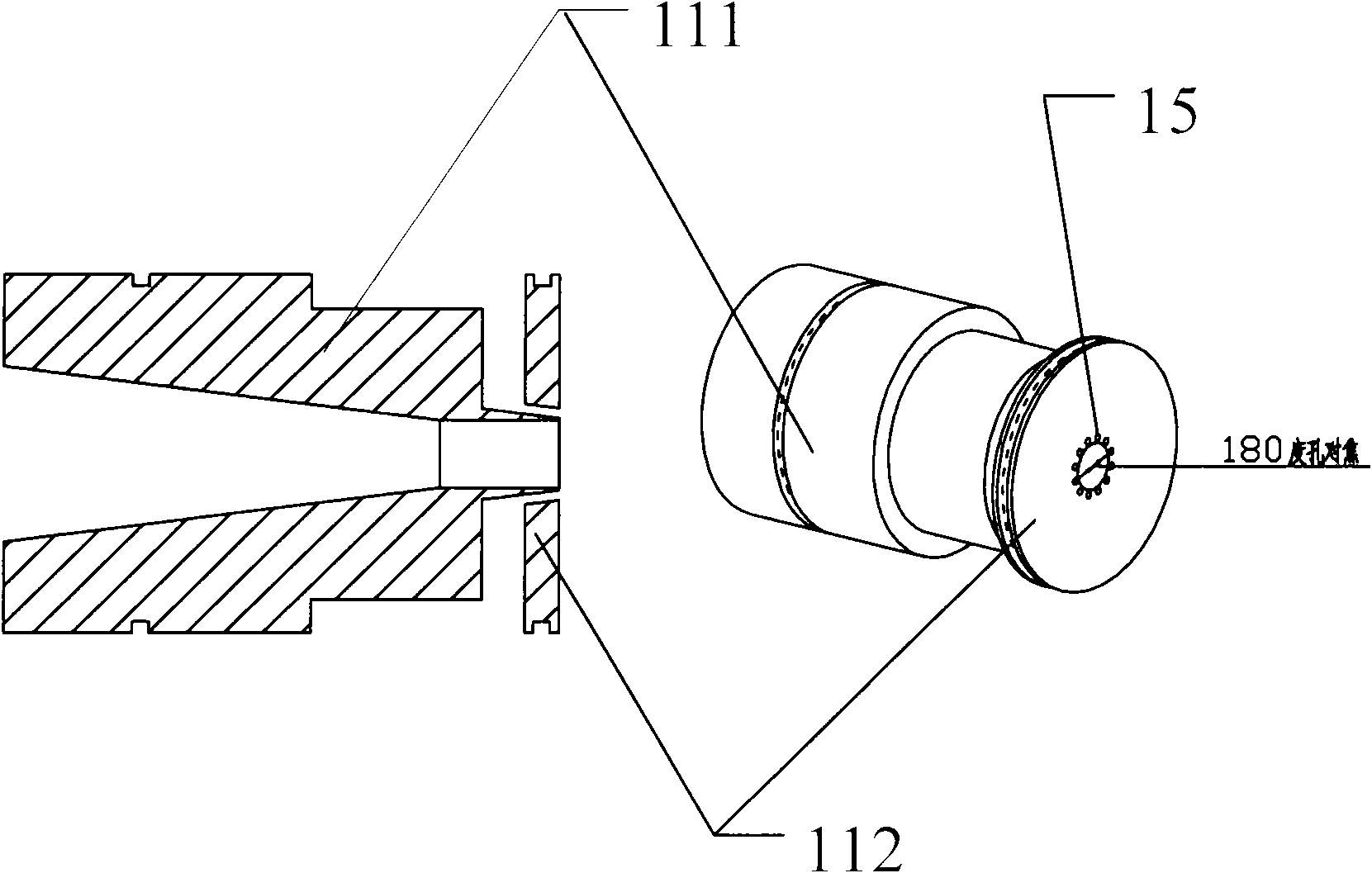

[0027] Adopt a preferred example below in conjunction with accompanying drawing to further illustrate this technical scheme:

[0028] The present invention is a water-gas miscible high-pressure cleaning equipment with water saving and energy saving, such as figure 1 As shown, it includes installation shell, cleaning gun, pressure sensing valve, auxiliary water pump 2, air pressure adjustment valve 6 (mainly including air pressure adjustment valve 61 and air pressure gauge 62), honeycomb Venturi high-pressure water-gas phase dissolution tank 1 and two buffer closures Valve 3, two main airway connecting pipes 5, branch airway connecting pipe 51, intermediate connecting pipe 52, all the above-mentioned devices are installed in the installation shell; among them, the installation shell, cleaning gun, and pressure sensing valve are conventional means in this field , can be understood and used by those of ordinary skill, so there is no label in the figure; the bronchus connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com