Renovation reinforcement, reinforced and/or crack arrest technique for pipe

A pipeline and reinforcement technology, applied in the direction of pipeline protection, protection of pipelines by thermal insulation, pipes/pipe joints/pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Example 1: Laying insulation material as the insulation performance of the composite material layer of the bottom layer

[0113] After the pipeline is reinforced with insulating material as the bottom layer, the insulation performance of the reinforced pipeline is tested. The pipe used is a steel pipe of φ60mm, and repaired according to the following steps:

[0114] 1) Clean the parts of the pipe body that need to be reinforced to remove the anti-corrosion layer, rust and other dirt on the outer surface of the pipe, and make the surface treatment quality reach the St3 level specified in GB / T8923-1988.

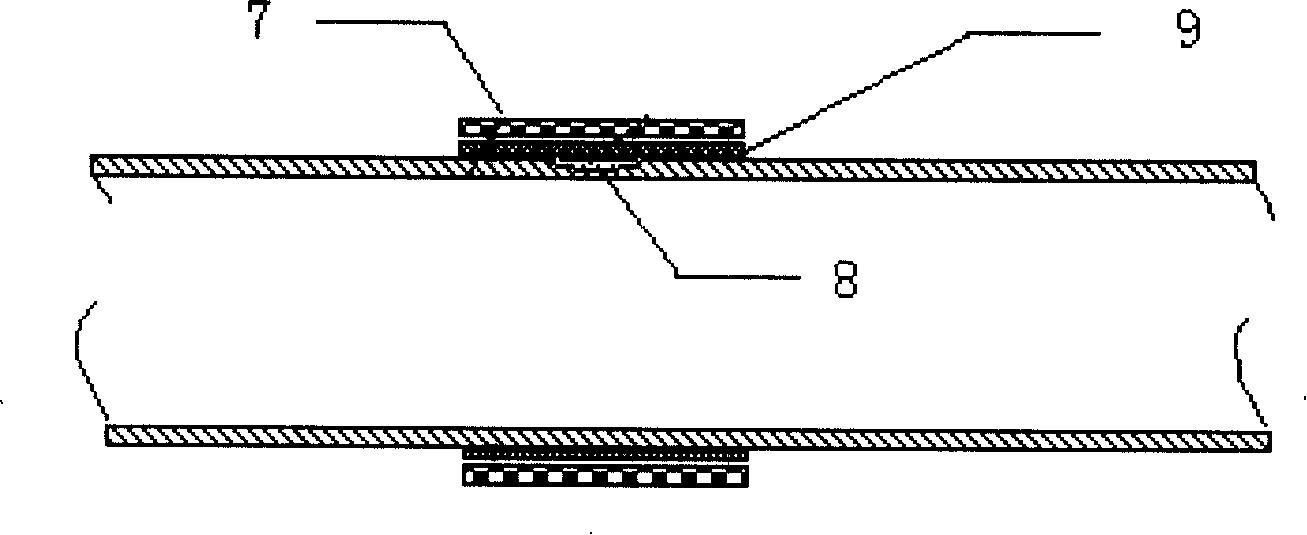

[0115] 2) The defect is filled with filling material epoxy mortar.

[0116] 3) After the surface of the filling material is dry, apply 2130 phenolic resin glue on the surface of the pipe, then lay unidirectional basalt fiber with a width of 300mm along the circumferential direction of the pipe, and roll it so that the curable polymer can be evenly impregnated with the u...

Embodiment 2

[0120] Embodiment 2: The technical solution of the present invention is evaluated by the hydraulic blasting test method

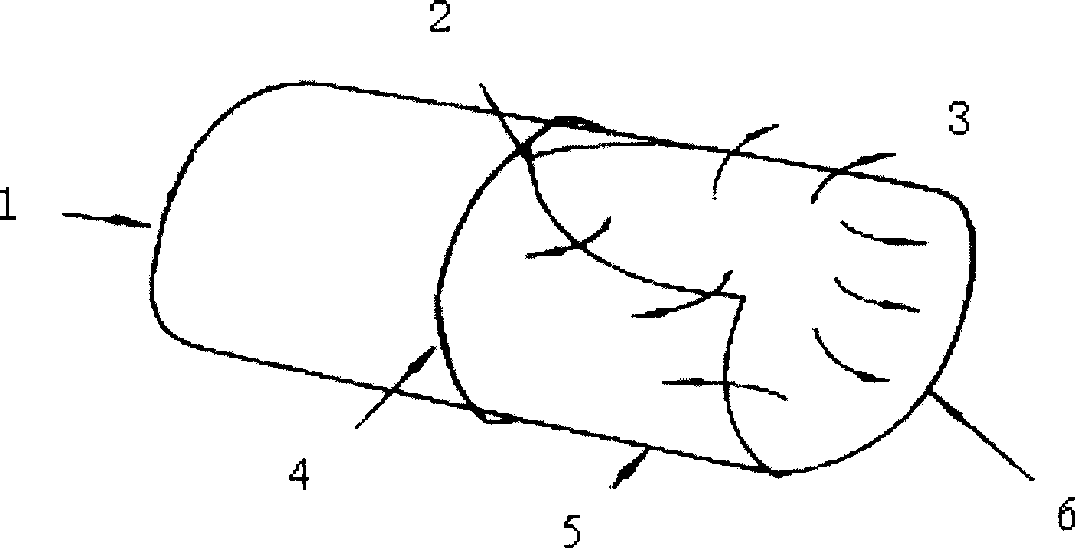

[0121] In order to test the implementation effect of the technical solution of the present invention, taking φ273 steel pipe as an example, simulating the size of defects that may exist in oil and gas pipelines, and evaluating the technology by using the hydraulic blasting test method. Test tubes, see image 3 , the schematic diagram of the defects on the experimental pipeline is shown in Figure 4 . The test process is as follows:

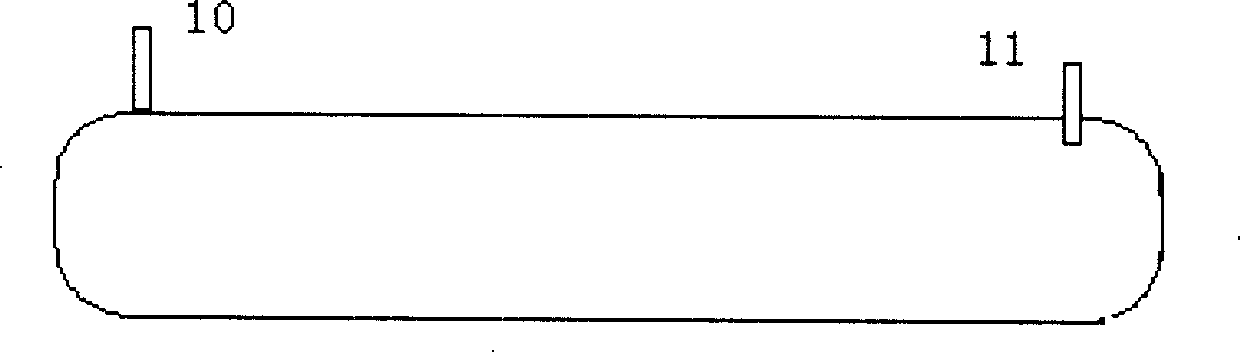

[0122] 1) Cut off 3m of commonly used pipes for oil and gas pipelines (the pipe is Q235 spiral welded pipe with a diameter of 273mm and a wall thickness of 7mm), and seal both ends with heads with vent holes and water inlet holes (see image 3 ).

[0123] 2) Make a defect whose size is 40mm×13.5mm×3.5mm.

[0124] 3) Clean the parts of the pipe body that need to be reinforced to remove the anti-corrosion layer, rust and oth...

Embodiment 3

[0129] Embodiment 3: The technical solution of the present invention is evaluated by the hydraulic blasting test method

[0130] Similar to Example 1, the spiral weld defect is reinforced with composite materials, and then the reinforcement effect is verified by hydrostatic blasting experiments.

[0131] The experimental process is as follows:

[0132] 1) Cut off 3.5m of commonly used pipes for oil and gas pipelines (the pipe is Q235 spiral welded pipe with a diameter of 325mm and a wall thickness of 7mm), and seal both ends with heads with vent holes and water inlet holes.

[0133] 2) Make a defect with a size of (length×width×depth=60mm×10mm×5.16mm) at the spiral weld of the pipeline.

[0134] 3) Degrease and derust the parts of the pipe body that need to be reinforced.

[0135] 4) Fill the defect with epoxy filling resin.

[0136] 5) After the surface of the filling material is dry, lay a 500mm wide aramid (1414) fiber prepreg (prepreg made of aramid fiber and epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com