Self-enhancement type polyolefin foaming material as well as preparation method and application thereof

A polyolefin foaming and reinforced technology, applied in the field of foaming materials, can solve the problems of not meeting the national standards for tension and torsion, damage, etc., and achieve the effects of high safety and environmental protection performance, increased tear strength, and increased process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A self-reinforced polyolefin foam material, comprising the following preparation raw materials by weight: LLDPE (melt index is 2.1g / 10min) 0.6kg, LDPE (melt index is 2.3g / 10min) 2.4kg; Amide (AC) 305g, di-tert-butylperoxycumene (BIPB) 29g, stearic acid 25g, zinc oxide 27.5g, talcum powder 2kg. Among them, LDPE is specifically selected from Yangzi BASF 2426H, and LLDPE is specifically selected from Relene of Reliance Industries Limited, and the mass percentage in the polyolefin is 20%.

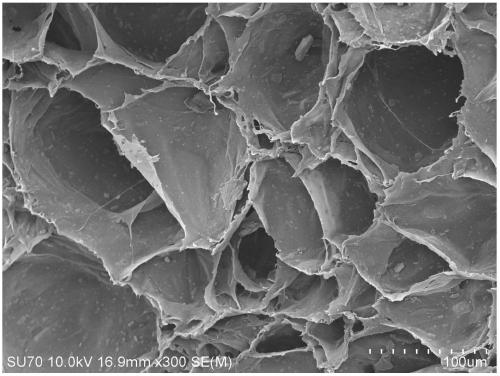

[0030] Its preparation method is as follows: Prepare the required raw materials as needed, put them in a closed rubber mixer for mixing and plasticizing treatment, wherein the temperature in the closed rubber mixer is 135°C and plasticize for 15 minutes and discharge; The material discharged from the machine is sent to the open mill for open refining and thinning for 15 minutes; after cooling, it is cut into slices and foamed in a press at 175°C to obtain the required self-reinforced pol...

Embodiment 2- Embodiment 5

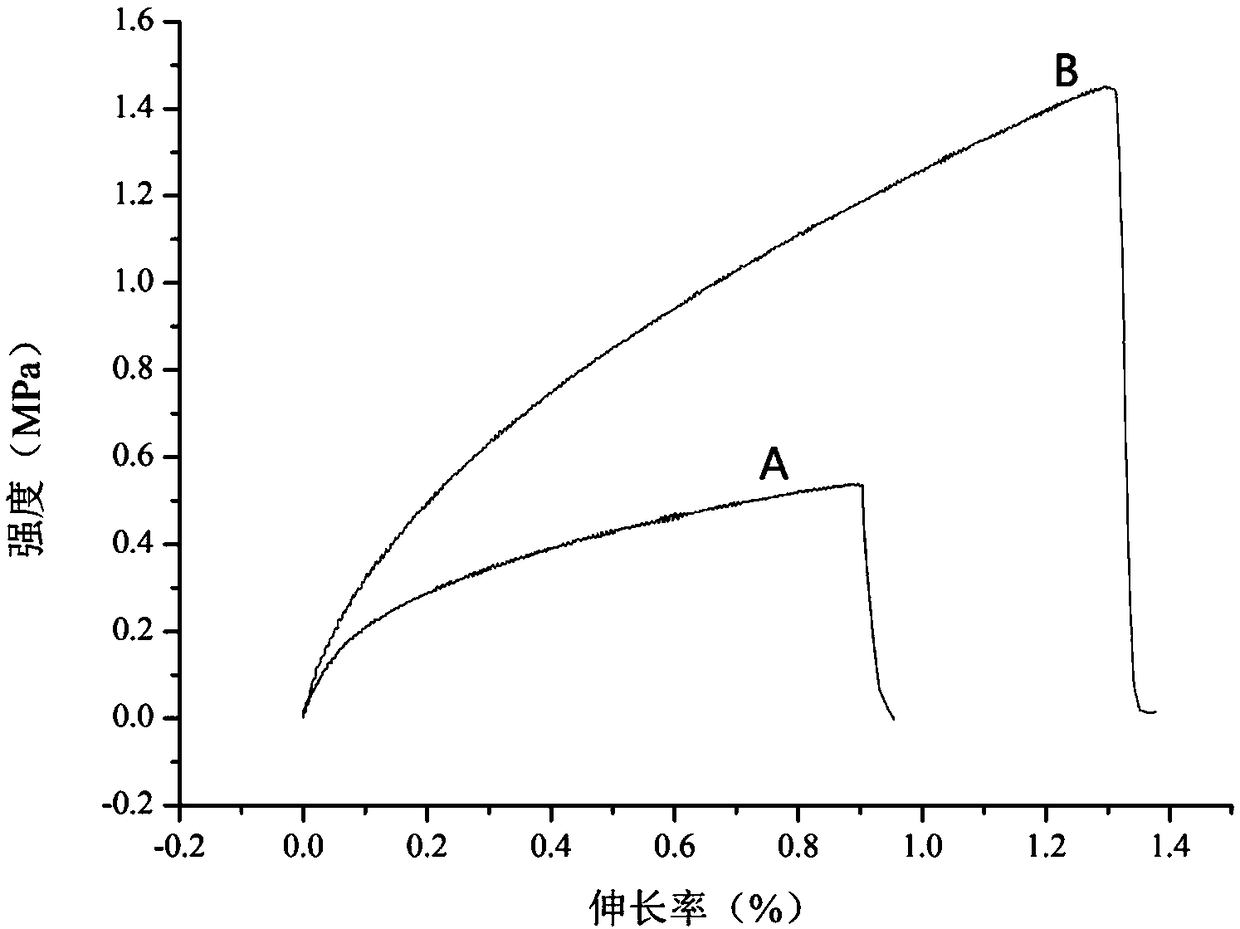

[0032] Except that the mass percent content of LLDPE in polyolefin is different, the types and amounts of other preparation raw materials are the same as in Example 1; and the preparation method is also the same as in Example 1, and the specific mass percent of LLDPE in the polymer in Examples 2-5 40%, 60%, 80%, 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com