Silane modified polyurethane adhesive for bottom layer material of plastic runway and preparation method and application of silane modified polyurethane adhesive

A polyurethane adhesive and silane modification technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as human health hazards, achieve easy construction, ensure resin purity, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment relates to a bottom layer material of a plastic runway, which is prepared according to the following steps:

[0045] S1. Preparation of silane-modified polyurethane adhesive: Heat 80g of polyether polyol D240 and 20g of polyether polyol F330N in a 500ml three-necked flask to 110°C, then vacuumize to -0.01MPa for dehydration for 3h, then cool down to 60°C, Add 0.02g of zinc isooctanoate, stir for 30 minutes, then add 21g of 3-isocyanatopropyl triethoxysilane dropwise to the polyether polyol within 30 minutes, react for 1h, then raise the temperature to 95°C, and continue the reaction for 2.5h , to obtain silane-modified polyurethane resin;

[0046] When the temperature of the silane-modified polyurethane is lowered to 65°C, add 0.3g of n-octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate and 0.1g of phosphoric acid, and stir for 0.5h to obtain silane Modified polyurethane adhesive.

[0047] S2. Prepare the bottom material of the plastic runway: W...

Embodiment 2

[0049] This embodiment relates to a bottom layer material of a plastic runway, which is prepared according to the following steps:

[0050] S1. Preparation of silane-modified polyurethane adhesive: Heat 80g of polyether polyol D230 and 20g of polyether polyol F330N in a 500ml three-neck flask to 110°C, vacuumize to -0.01MPa for dehydration for 2h, then cool to 70°C, add 0.04g of dibutyltin dilaurate, stirred for 30 minutes, then added 24g of 3-isocyanatopropyl triethoxysilane dropwise to the polyether polyol within 30 minutes, reacted for 2 hours, raised the temperature to 95°C, and continued the reaction for 1.5 h, obtaining silane-modified polyurethane resin;

[0051] When the silane-modified polyurethane cools down to 60°C, add 0.2g of n-octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate and 0.1g of di-isooctyl phosphate, and stir for 1h , to obtain a silane-modified polyurethane adhesive.

[0052] S2, prepare the bottom material of the plastic runway: Weigh the bl...

Embodiment 3

[0054] This embodiment relates to a bottom layer material of a plastic runway, which is prepared according to the following steps:

[0055] S1. Preparation of silane-modified polyurethane adhesive: Heat 80g of polyether polyol D210 and 20g of polyether polyol F330N in a 500ml three-neck flask to 110°C, vacuumize to -0.01MPa for 2 hours, then cool down to 70°C, add 0.04g of bismuth isooctanoate, stirred for 30 minutes, then added dropwise 27g of 3-isocyanatopropyltrimethoxysilane into polyether polyol within 30 minutes, reacted for 2 hours, raised the temperature to 95°C, and continued to react for 1.5 hours to obtain Silane modified polyurethane resin;

[0056] When the silane-modified polyurethane cools down to 60°C, add 0.3g of β(3,5-di-tert-butyl-4-hydroxyphenyl) octyl propionate and 0.2g of di-isooctyl phosphate, and stir for 1 hour to obtain silane-modified polyurethane adhesive.

[0057] S2. Prepare the bottom material of the plastic runway: Weigh black rubber particle...

PUM

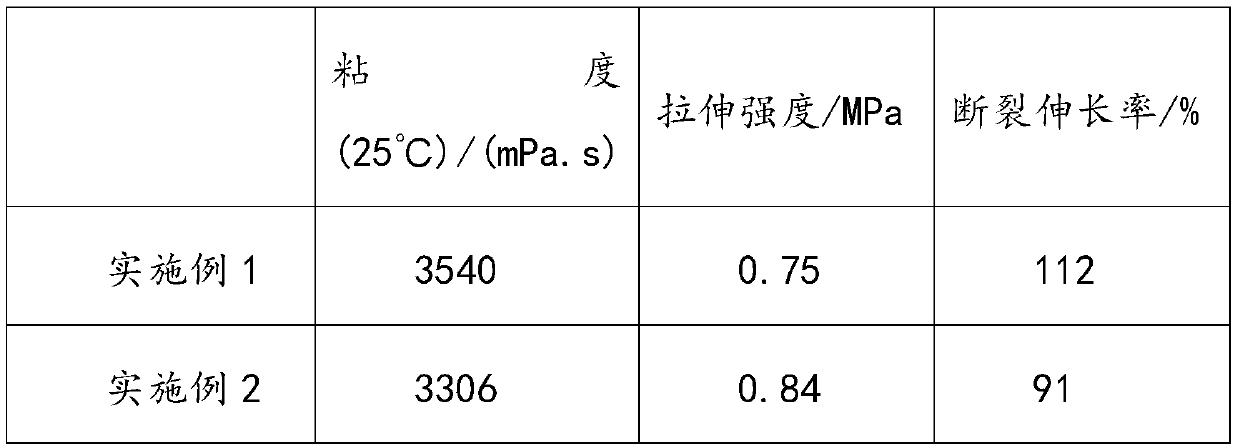

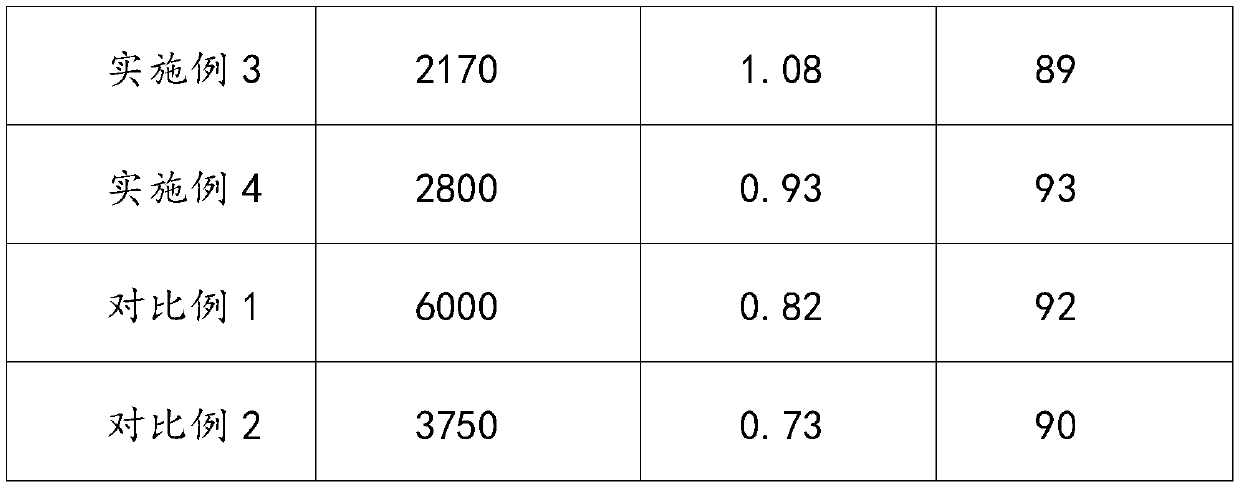

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com