Waterborne acrylic wear-resistant road marking paint and preparation method thereof

A water-based acrylic, road marking technology, applied in coatings and other directions, can solve the problems of poor wear resistance, reduced strength and toughness of the paint film, uneven curing, etc., to improve mechanical properties, improve safety and environmental protection performance, improve gloss retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

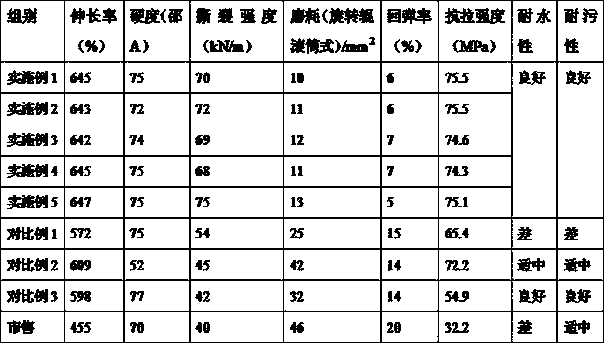

Examples

Embodiment 1

[0031]Composition of raw materials (parts by weight): 100 parts of modified acrylic resin, 1 part of diacetone acrylamide, 1 part of dihydrazine adipate, 5 parts of neopentyl glycol, 7 parts of maleic anhydride, and 10 parts of coalescent , 10 parts of filler, 2003 parts of polyethylene glycol and 1 part of GPE type defoamer. The film-forming aid is composed of the following raw materials in weight percentage: 20% of adipate, 35% of propylene glycol block polyether, 12% of triethoxyoctylsilane and 33% of polyethylene glycol 4000. The filler is 800 mesh calcium powder.

[0032] The modified acrylic resin is prepared from the following raw materials in parts by weight: 20 parts of methyl methacrylate, 10 parts of n-butyl acrylate, 15 parts of acrylic acid, 15 parts of hydroxyethyl acrylate, 20 parts of isocyanate, 5 parts of silicon dioxide, 1 part of silane coupling agent KH5501, 7 parts of dodecafluoroheptyl methacrylate, 3 parts of triethoxysilane, 50 parts of glycidyl tert-...

Embodiment 2

[0038] Raw material composition (parts by weight): 200 parts of modified acrylic resin, 3 parts of diacetone acrylamide, 3 parts of dihydrazine adipate, 15 parts of neopentyl glycol, 17 parts of maleic anhydride, 20 parts of film-forming aid , 15 parts of filler, 7 parts of styrene-maleic anhydride and 5 parts of silicone defoamer. The film-forming aid is composed of the following raw materials in weight percentage: 20% of adipate, 35% of propylene glycol block polyether, 12% of triethoxyoctylsilane and 33% of polyethylene glycol 4000. The filler is 800 mesh calcium powder.

[0039] The modified acrylic resin is prepared from the following raw materials by weight: 50 parts of methyl methacrylate, 30 parts of n-butyl acrylate, 25 parts of acrylic acid, 35 parts of hydroxyethyl acrylate, 40 parts of isocyanate, 10 parts of silicon dioxide, 3 parts of silane coupling agent KH550, 12 parts of dodecafluoroheptyl methacrylate, 7 parts of triethoxysilane, 100 parts of glycidyl terti...

Embodiment 3

[0045] Raw material composition (parts by weight): 140 parts of modified acrylic resin, 2 parts of diacetone acrylamide, 1 part of dihydrazine adipate, 7 parts of neopentyl glycol, 10 parts of maleic anhydride, 12 parts of film-forming aid , 12 parts of filler, 4 parts of polycarboxylate ammonium salt and 2 parts of silicone defoamer. The film-forming aid is composed of the following raw materials in weight percentage: 20% of adipate, 35% of propylene glycol block polyether, 12% of triethoxyoctylsilane and 33% of polyethylene glycol 4000. The filler is 800 mesh calcium powder.

[0046] The modified acrylic resin is prepared from the following raw materials in parts by weight: 30 parts of methyl methacrylate, 15 parts of n-butyl acrylate, 17 parts of acrylic acid, 20 parts of hydroxyethyl acrylate, 25 parts of isocyanate, 7 parts of silicon dioxide, 1 part of silane coupling agent KH5501, 8 parts of dodecafluoroheptyl methacrylate, 4 parts of triethoxysilane, 60 parts of glyci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com