Alcohol type gravure surface printing ink and preparation method thereof

A gravure and ink technology, applied in the direction of ink, household utensils, pigment paste, etc., can solve the problems of poor gloss, small application range, dry surface and plugged plate, etc., achieve stable and excellent coloring power and friction coefficient, and reduce toxic solvents The effect of using, safety and environmental performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 Gravure surface ink binder of the present invention and gravure surface ink made therefrom

[0047] The first step: preparing gravure surface ink binder. The gravure surface ink binder of the present invention is made up of the following components by weight:

[0048] Polyvinyl butyral resin: 25 parts

[0049] Delrin: 4 parts

[0050] Anhydrous alcohol: 57 parts

[0051] Ethyl acetate: 14 parts

[0052] Preparation process: Weigh the components of the above prescription by weight, add the ingredients in sequence, stir at a medium speed for 20-30 minutes, and completely dissolve to obtain the gravure surface ink binder of the present invention.

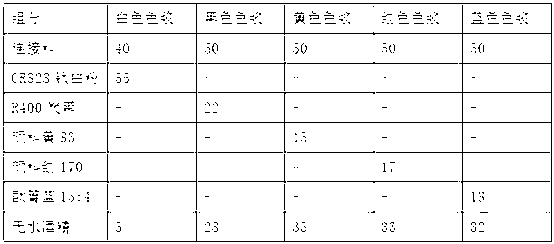

[0053] The second step: prepare the color paste composition. A color paste composition was further prepared by using the above gravure surface ink binder, and the composition of the color paste composition is shown in Table 1.

[0054] Table 1 The weight composition of color paste composition o...

Embodiment 2

[0061] Embodiment 2 Gravure surface ink binder of the present invention and gravure surface ink made therefrom

[0062] The first step: preparing gravure surface ink binder. The gravure surface ink binder of the present invention is made up of the following components by weight:

[0063] Polyvinyl butyral resin: 20 parts

[0064] Delrin: 2 parts

[0065] Anhydrous alcohol: 47 parts

[0066] Ethyl acetate: 10 parts

[0067] Preparation process: Weigh the components of the above prescription by weight, add the ingredients in sequence, stir at a medium speed for 20-30 minutes, and completely dissolve to obtain the gravure surface ink binder of the present invention.

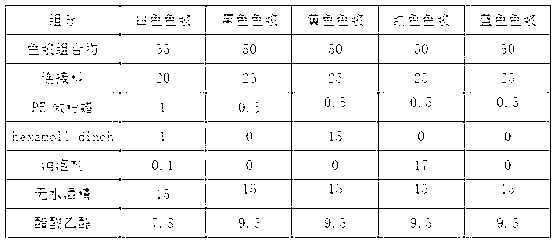

[0068] The second step: prepare the color paste composition. A color paste composition was further prepared by using the above gravure surface ink binder, and the composition of the color paste composition is shown in Table 3.

[0069] Table 3 The weight composition of color paste composition of th...

Embodiment 3

[0076] Embodiment 3 gravure surface ink binder of the present invention and the gravure surface ink made by it

[0077] The first step: preparing gravure surface ink binder. The gravure surface ink binder of the present invention is made up of the following components by weight:

[0078] Polyvinyl butyral resin: 30 parts

[0079] Delrin: 6 parts

[0080] Anhydrous alcohol: 60 parts

[0081] Ethyl acetate: 18 parts

[0082] Preparation process: Weigh the components of the above prescription by weight, add the ingredients in sequence, stir at a medium speed for 20-30 minutes, and completely dissolve to obtain the gravure surface ink binder of the present invention.

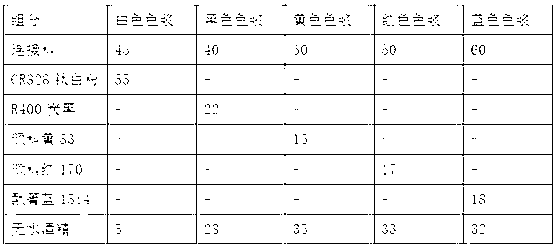

[0083] The second step: prepare the color paste composition. A color paste composition was further prepared by using the above gravure surface ink binder, and the composition of the color paste composition is shown in Table 5.

[0084] Table 5 The weight composition of color paste composition of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com