Compostable full-degradable disposable tableware and preparation method thereof

A one-time, fully degradable technology, applied in the field of biodegradable materials, can solve the problems of not fully degradable, permanent pollution, unavoidable, etc., to achieve the effect of reducing energy consumption, reducing production improvement costs, and high safety and environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

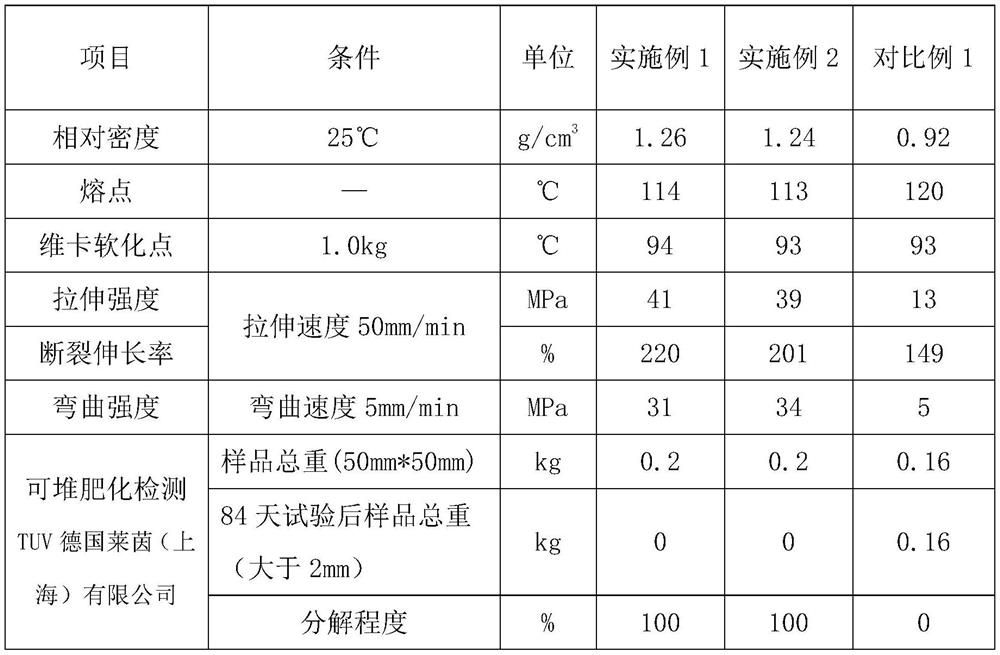

Examples

Embodiment 1

[0038]A compostable and fully degradable disposable tableware, including the following preparation raw materials calculated by weight: containing 65 parts of PBS, 35 parts of PBAT, 20 parts of bamboo powder, 20 parts of calcium carbonate, 0.5 parts of stearic acid, and 0.5 parts of chain extender , 4 parts of paraffin wax, 0.3 parts of antioxidant 1010.

[0039]PBS uses Xinjiang Lanshan Tunhe Polyester Co., Ltd. TH-803A, and its melt index is 15.0g / 10min. PBAT selects TH-801T from Xinjiang Lanshan Tunhe Polyester Co., Ltd., and its melt index is 4.5g / 10min. The chain extender is BASF JoncrylADR4468.

[0040]The preparation method is as follows:

[0041]1) Put the bamboo powder and calcium carbonate in a high-speed mixer and mix for 10 minutes at 800 rpm for drying and dehumidification, then add stearic acid and antioxidant 1010 and continue to mix and heat for 5 minutes at 800 rpm in the high-speed mixer to obtain a mixed powder .

[0042]2) Put PBAT, PBS, chain extender, and paraffin into a hi...

Embodiment 2

[0048]A compostable and fully degradable disposable tableware, including the following preparation raw materials calculated by weight: containing 50 parts of PBS, 35 parts of PBAT, 15 parts of PLA, 10 parts of straw powder, 15 parts of talcum powder, 5 parts of titanate, and 0.01 part of dicumyl oxide (DCP), 0.5 part of maleic anhydride (MHA), TPW6041 part, and 0.6 part of antioxidant MB.

[0049]PBS uses Xinjiang Lanshan Tunhe Polyester Co., Ltd. TH-803A, and its melt index is 15.0g / 10min. PBAT selects TH-801T from Xinjiang Lanshan Tunhe Polyester Co., Ltd., and its melt index is 4.5g / 10min. NatureWorks2003D is selected for PLA, and the melt index MI value (210°C, 2160g) range is 6.0g / 10min.

[0050]The preparation method is as follows:

[0051]1) Put the straw powder and talc powder in a high-speed mixer at 800 rpm and mix for 10 minutes for drying and dehumidification, then add titanate, TPW604, and antioxidant MB to continue mixing and heating at 800 rpm for 5 minutes to obtain mixed pow...

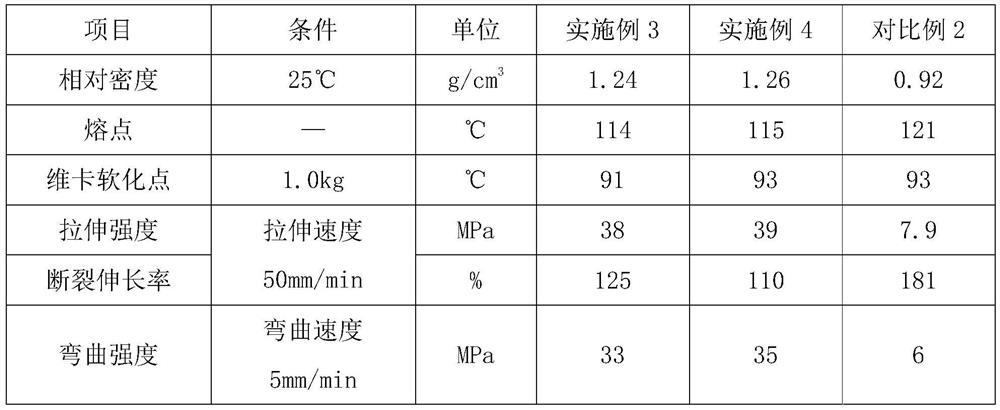

Embodiment 3

[0065]A compostable and fully degradable disposable tableware, including the following preparation raw materials calculated by weight: containing 100 parts of PBS, 20 parts of bamboo powder, 15 parts of calcium carbonate, 2 parts of silane coupling agent KH550, 3 parts of chain extender, poly 2 parts of ethylene wax and 0.4 parts of antioxidant 1010.

[0066]PBS uses Xinjiang Lanshan Tunhe Polyester Co., Ltd. TH-803A, and its melt index is 15.0g / 10min. The chain extender is Quansheng Chemical X-U992.

[0067]The preparation method is as follows:

[0068]1) Put the bamboo powder and calcium carbonate in a high-speed mixer at 800 rpm and mix for 10 minutes to dry and dehumidify, then add the silane coupling agent KH550 and antioxidant 1010 and continue to mix and heat at the high-speed mixer at 800 rpm for 5 minutes to obtain a mixture Powder.

[0069]2) Put PBS, chain extender, and polyethylene wax into a high-speed mixer at a rotation speed of 600 rpm and a temperature of 70° C. and mix for 8 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com