Polymer dispersion liquid and application thereof

A polymer and dispersion technology, applied in electrochemical generators, electrical components, circuits, etc., can solve problems such as battery performance degradation, and achieve the effect of protecting metal lithium and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

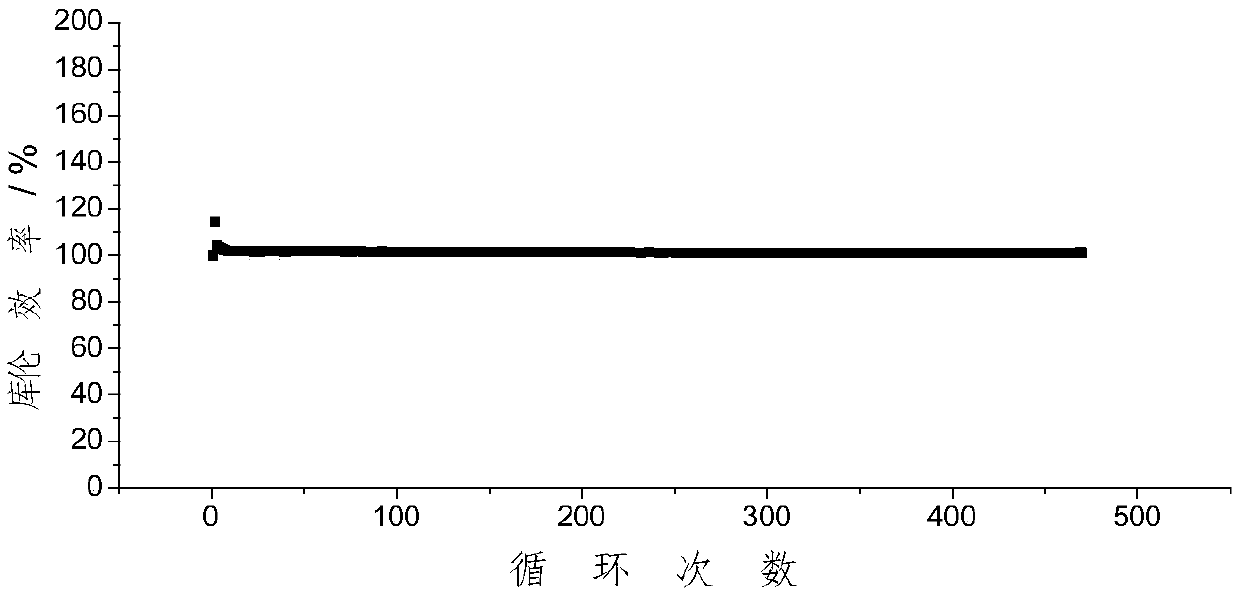

[0029] Add 1 g of lithium bistrifluoromethanesulfonimide to 7.5 g of ethylene glycol dimethyl ether, and stir vigorously to obtain a clear electrolyte. Add 2.5 g of dioxolane and perfluorosulfonic acid resin therein, and heat to 70° C. to polymerize dioxolane into polydioxolane. It is still a transparent liquid after polymerization. A lithium / copper model battery was assembled using the polymer dispersion obtained above as an electrolyte. The lithium / copper model battery assembly method is as follows: put the stainless steel spring gasket, lithium sheet, electrolyte, Celgard2325 diaphragm, electrolyte, and pure copper foil discs into the 2016 button battery in sequence, and the amount of electrolyte dropped to 40uL, assemble the cell in an argon-filled glove box. The model battery is stamped and packaged with a press. The battery was tested in constant current charge and discharge mode. First control the capacity discharge, deposit 1mAh / cm on the surface of copper foil 2 ...

Embodiment 2

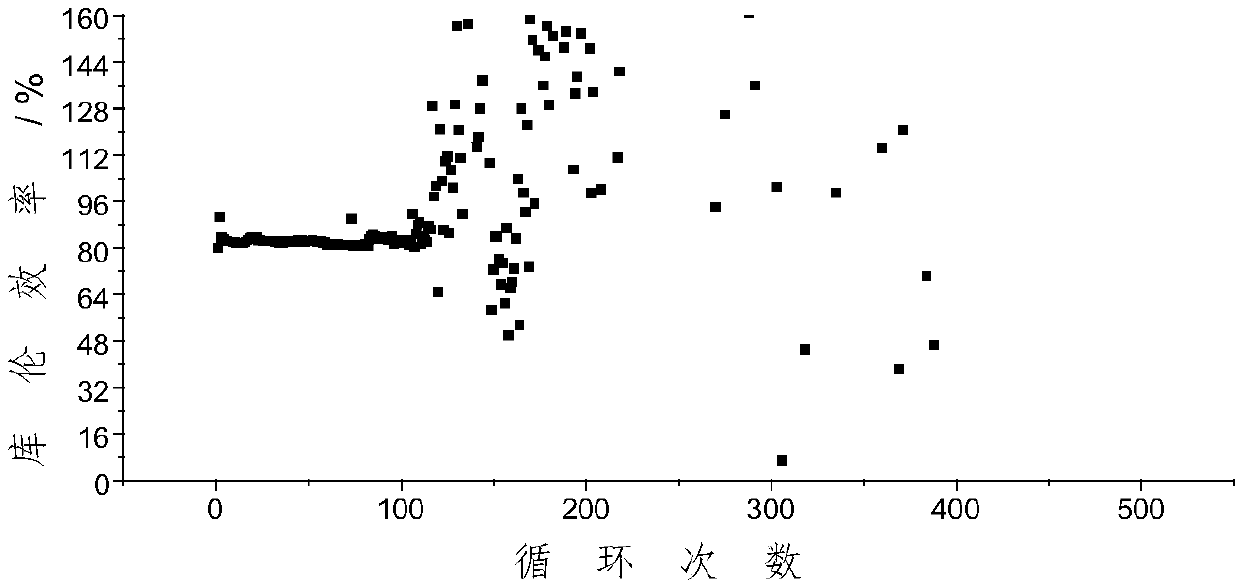

[0037] Add 1 g of lithium bisfluorosulfonimide to 7.5 g of polypropylene carbonate, and stir vigorously to obtain a clear electrolyte. 2.0 g of ethylene oxide was added therein, and the ethylene oxide was polymerized into polyethylene glycol by ultraviolet irradiation. It is still a transparent liquid after polymerization. Assembling the lithium / copper model battery with the polymer dispersion obtained above as the electrolyte, the dissolution and deposition cycle life of metal lithium can reach 300 times, and the average coulombic efficiency is 97.5%;

Embodiment 3

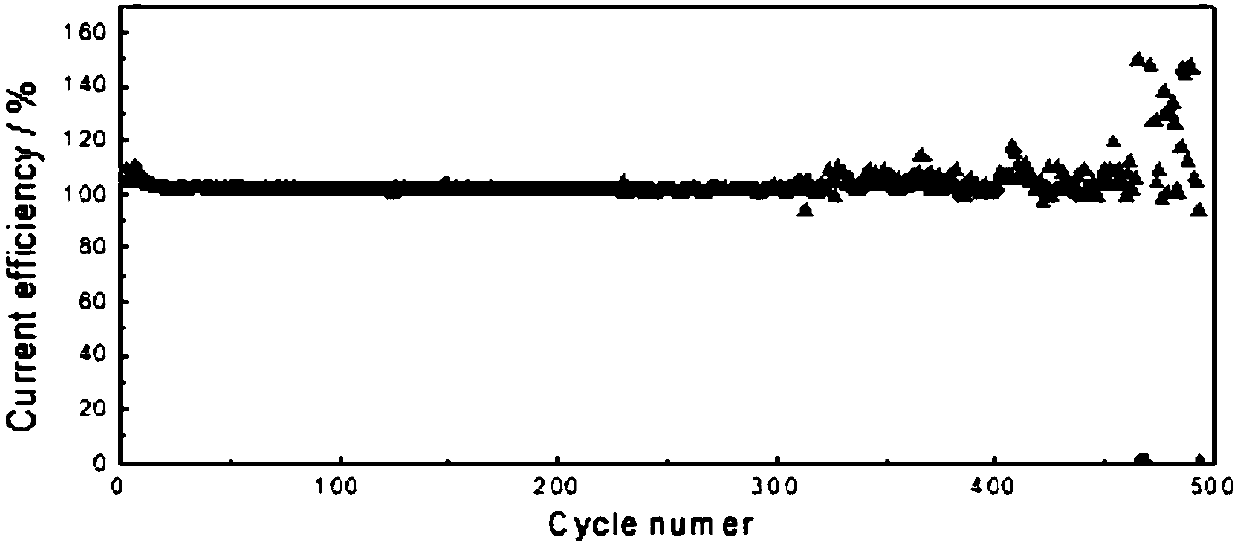

[0039] Add 1 g of lithium bisfluorosulfonimide to 7.5 g of polypropylene carbonate, and stir vigorously to obtain a clear electrolyte. 2.5 g of ethylene oxide and 1 mg of azobisisobutyronitrile were added thereto, and the ethylene oxide was polymerized into polyethylene glycol by ultraviolet irradiation. It is still a transparent liquid after polymerization. Compared with using the polymer dispersion obtained above as the electrolyte to assemble the lithium / copper model battery, the dissolution and deposition cycle life of metal lithium can reach 300 times, and the average coulombic efficiency is 97.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com