Method for improving weatherability of outdoor woodware

A wood product and weather resistance technology, which is applied in the field of outdoor wood product surface treatment, can solve problems such as cracking, poor paint quality, discoloration, etc., and achieve the effect of simple process, low cost, and prevention of infiltration and oxidative gas infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

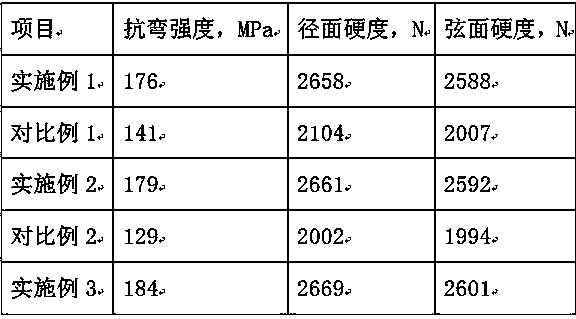

Examples

Embodiment 1

[0019] A method for improving the weather resistance of outdoor wood products, comprising the following steps:

[0020] (1) In parts by weight, 34 parts of benzoin trunk, 25 parts of Akebia officinalis, and 18 parts of Zhemu were cut into wood chips with a weight of 10g by a chipper, and then mixed evenly, and 0.6 times the weight of petroleum ether was added to the wood chips , after 90 hours of ultrasonic extraction treatment, after heating to remove petroleum ether, the primary product of mixed tree oil was obtained, and then 10% of the volume of concentrated sulfuric acid with a mass fraction of 92.5% was added to the mixed tree oil, and heat preservation and stirring treatment at 45°C for 2 hours Finally, let it stand for 12 hours, and remove the lower layer. The upper layer adopts a mass fraction of 20% sodium hydroxide solution to neutralize the pH to 6.5 to obtain the mixed tree oil product. After the concentrated sulfuric acid and sodium hydroxide solution are processe...

Embodiment 2

[0030] A method for improving the weather resistance of outdoor wood products, comprising the following steps:

[0031] (1) In parts by weight, 36 parts of benzoin trunk, 28 parts of Akebia officinalis, and 20 parts of Zhemu are cut into wood chips with a weight of 15g by a chipper, and then mixed evenly, and 0.7 times the weight of petroleum ether is added to the wood chips , after 95 hours of ultrasonic leaching treatment, after heating to remove petroleum ether, the primary product of mixed tree oil was obtained, and then 13% by volume of concentrated sulfuric acid with a mass fraction of 92.5% was added to the mixed tree oil, and heat preservation and stirring treatment at 48°C for 2.5 hours Finally, let it stand for 12 hours, then remove the lower layer, the upper layer is 20% sodium hydroxide solution and the pH is 7.0 to obtain the mixed tree oil product, after the concentrated sulfuric acid and sodium hydroxide solution are processed, the mixed tree oil can be improved....

Embodiment 3

[0041] A method for improving the weather resistance of outdoor wood products, comprising the following steps:

[0042] (1) In parts by weight, 40 parts of benzoin trunk, 30 parts of Akebia officinalis, and 22 parts of Zhemu are cut into wood chips with a weight of 20g by a chipper, and then mixed evenly, and 0.8 times the weight of petroleum ether is added to the wood chips , after 100 hours of ultrasonic extraction treatment, after heating to remove petroleum ether, the primary product of mixed tree oil was obtained, and then 15% by volume of concentrated sulfuric acid with a mass fraction of 92.5% was added to the mixed tree oil, and the treatment was carried out at 50°C for 3 hours with stirring Finally, let it stand for 12 hours, then remove the lower layer. The upper layer is neutralized with 20% sodium hydroxide solution and the pH is 6.5-7.5 to obtain the mixed tree oil product. After being treated with concentrated sulfuric acid and sodium hydroxide solution, it can im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com