Formula of trivalent chromium colored zinc passivator with strong antirust performance

A technology with anti-rust performance and trivalent chromium, which is applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve difficult problems, achieve strong anti-rust performance, strong anti-corrosion performance, safety and environmental protection high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

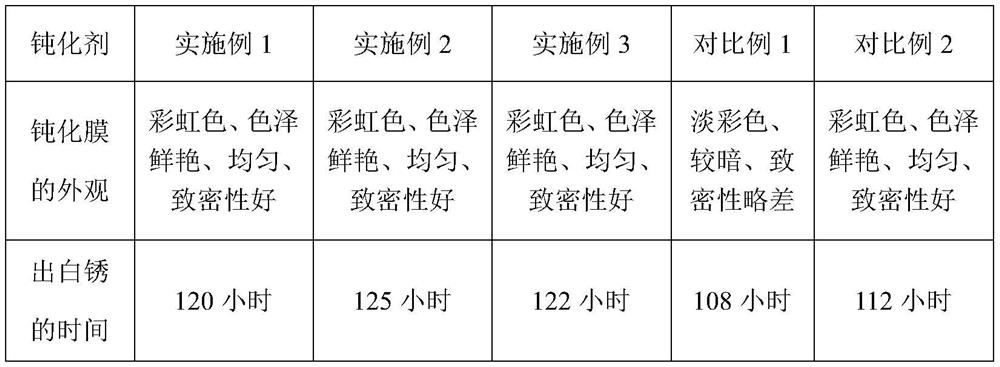

Examples

Embodiment 1

[0045] A formula of trivalent chromium color zinc passivation agent with strong anti-rust performance, weighing raw materials according to parts by weight:

[0046] Chromium chloride: 5 parts;

[0047] Citric acid: 5 parts;

[0048] Sodium nitrate: 5 parts;

[0049] Sodium chloride: 1 part;

[0050] Cerium sulfate: 0.5 part;

[0051] Blocking agent: 1 serving;

[0052] Deionized water: 20 parts;

[0053] The preparation method includes the following steps:

[0054] (1) dissolving chromium chloride in deionized water to obtain an aqueous solution containing trivalent chromium ions;

[0055] (2) add sodium nitrate, sodium chloride, cerium sulfate, blocking agent to the aqueous solution containing trivalent chromium ions, after stirring and dissolving, add citric acid again, fully stirring and dissolving, and finally adding a phosphoric acid solution with a concentration of 85% ( That is, 100 g of phosphoric acid solution contains 85 g of phosphoric acid) to adjust the pH ...

Embodiment 2

[0057] A formula of trivalent chromium color zinc passivation agent with strong anti-rust performance, weighing raw materials according to parts by weight:

[0058] Chromium sulfate: 30 parts;

[0059] 2,3-Dihydroxysuccinic acid: 20 parts;

[0060] Sodium nitrate: 20 parts;

[0061] Sodium chloride: 10 parts;

[0062] Cerium sulfate: 2 parts;

[0063] Sealing agent: 5 parts;

[0064] Deionized water: 65 parts;

[0065] The preparation method includes the following steps:

[0066] (1) dissolving chromium chloride in deionized water to obtain an aqueous solution containing trivalent chromium ions;

[0067] (2) Add sodium nitrate, sodium chloride, cerium sulfate, and a blocking agent to the aqueous solution containing trivalent chromium ions, and after stirring and dissolving, add 2,3-dihydroxysuccinic acid, and fully stir and dissolve. The final concentration is 85% phosphoric acid solution (ie 85 g phosphoric acid in 100 g phosphoric acid solution) adjusts the pH value o...

Embodiment 3

[0069] A formula of trivalent chromium color zinc passivation agent with strong anti-rust performance, weighing raw materials according to parts by weight:

[0070] Chromium chloride: 20 parts;

[0071] Gluconic acid: 15 servings;

[0072] Sodium nitrate: 10 parts;

[0073] Sodium chloride: 5 parts;

[0074] Cerium sulfate: 1.5 parts;

[0075] Sealing agent: 3 parts;

[0076] Deionized water: 50 parts;

[0077] The preparation method includes the following steps:

[0078] (1) dissolving chromium chloride in deionized water to obtain an aqueous solution containing trivalent chromium ions;

[0079] (2) add sodium nitrate, sodium chloride, cerium sulfate, blocking agent to the aqueous solution containing trivalent chromium ions, after stirring and dissolving, then add gluconic acid, fully stirring and dissolving, and finally adding a phosphoric acid solution with a concentration of 85% ( That is, 100 g of phosphoric acid solution contains 85 g of phosphoric acid) to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com