Interior wall latex paint containing oxidized corn starch and preparation method thereof

A technology for oxidizing corn starch and interior wall latex paint, applied to the field of interior wall latex paint, can solve the problems of suboptimal effect, influence of scrub resistance, low content of organic volatiles, etc. The effect of improving safety and environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

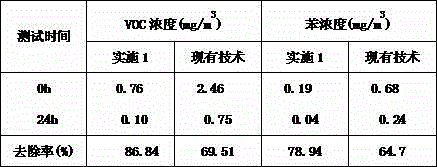

Examples

Embodiment 1

[0015] Weigh raw materials (kg) according to the following weight: oxidized corn starch 4-8, trimethylamine 0.6-0.9, bamboo carbon powder 1-2, photocatalyst 0.2-0.4, vinegar-acrylic emulsion 12-18, hydroxyethyl cellulose thickener 0.2~0.6, wetting and dispersing agent 0.1~0.3, defoamer 0.1~0.3, film-forming aid 0.6~0.9, titanium dioxide 6~10, heavy calcium 15~20, calcined kaolin 4~9, talc powder 4~10 , preservative 0.15~0.35, antifungal agent 0.15~0.35; and measure 160~170L of water.

[0016] Preparation:

[0017] Add water to the stirring tank first, slowly add oxidized cornstarch under stirring, stir and infiltrate, then add trimethylamine, hydroxyethyl cellulose thickener, wetting and dispersing agent, defoamer, film-forming aid in sequence; then Add titanium dioxide, heavy calcium, bamboo carbon powder, photocatalyst, calcined kaolin, talcum powder; turn to low speed, add vinegar-acrylic emulsion, preservative, anti-fungal agent and stir evenly; heat to 85°C, stir and rea...

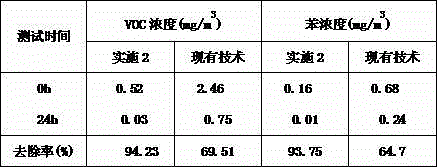

Embodiment 2

[0022] Weigh raw materials (kg) according to the following weight: oxidized corn starch 6, trimethylamine 0.8, bamboo carbon powder 1.5, photocatalyst 0.3, vinegar-acrylic emulsion 15, hydroxyethyl cellulose thickener 0.4, wetting and dispersing agent 0.15, defoaming 0.2 of agent, 0.7 of film-forming aid, 8 of titanium dioxide, 17 of heavy calcium, 5 of calcined kaolin, 7 of talcum powder, 0.2 of preservative, and 0.2 of antifungal agent; and measure 170L of water.

[0023] Preparation:

[0024] Add water to the stirring tank first, slowly add oxidized cornstarch under stirring, stir and infiltrate, then add trimethylamine, hydroxyethyl cellulose thickener, wetting and dispersing agent, defoamer, film-forming aid in sequence; then Add titanium dioxide, heavy calcium, bamboo carbon powder, photocatalyst, calcined kaolin, talcum powder; turn to low speed, add vinegar-acrylic emulsion, preservative, anti-fungal agent and stir evenly; heat to 85°C, stir and react at constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com