Patents

Literature

55results about How to "Continuous filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

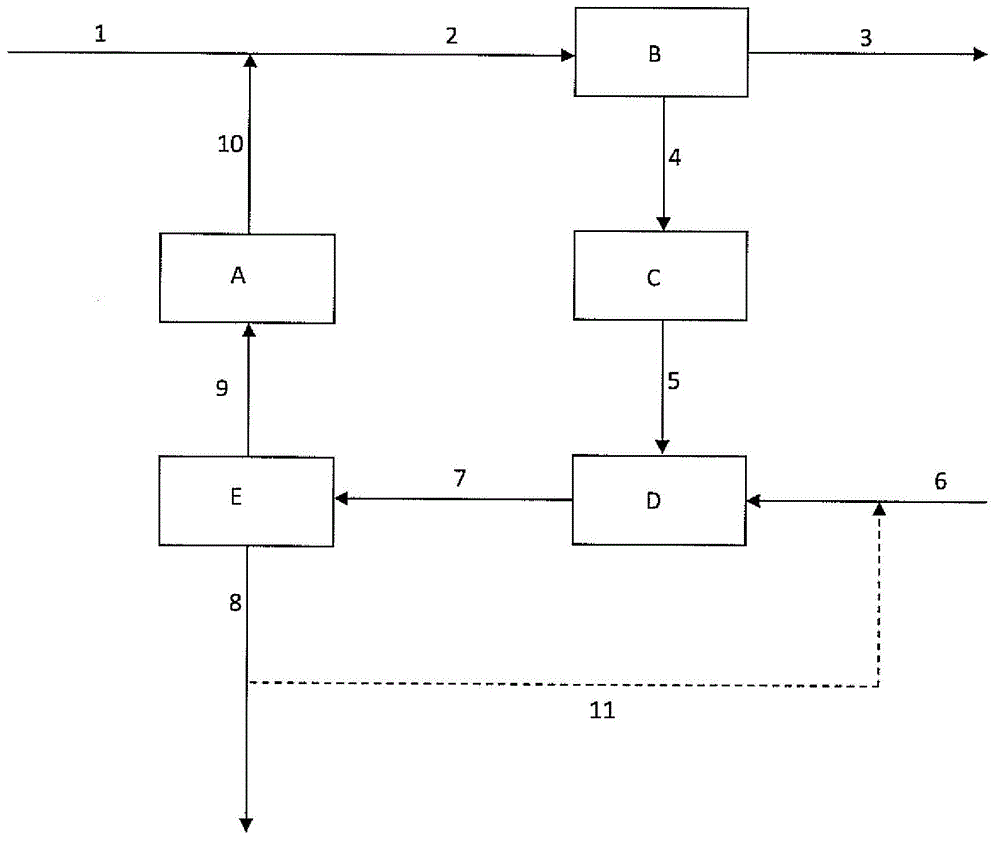

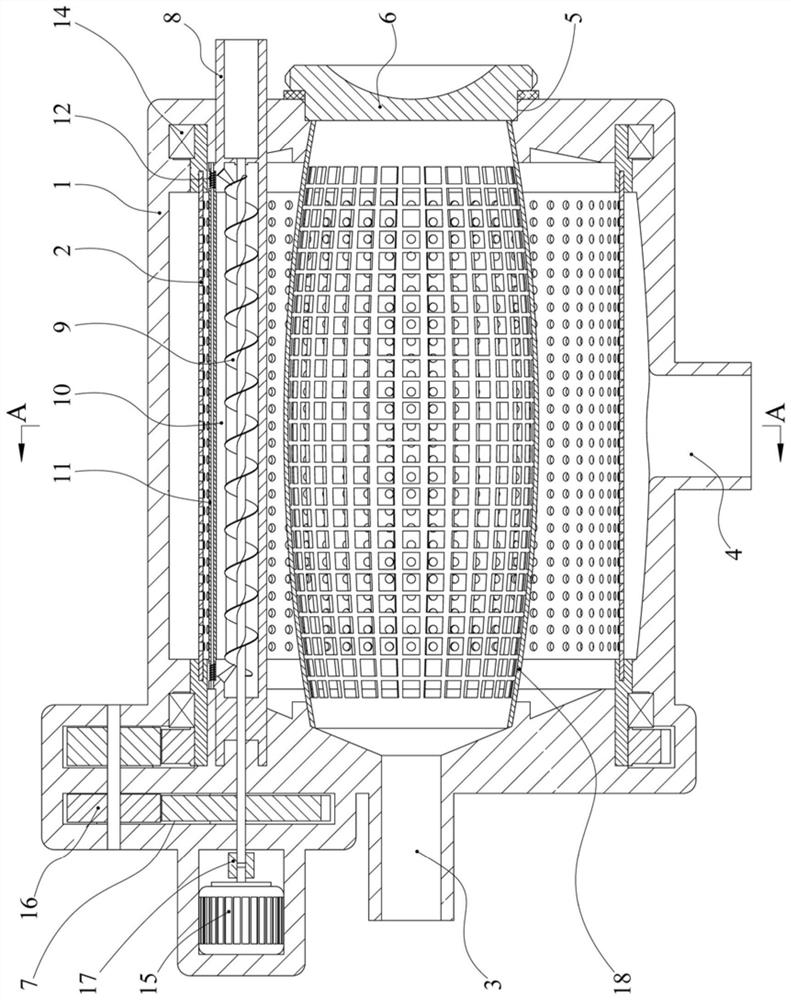

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

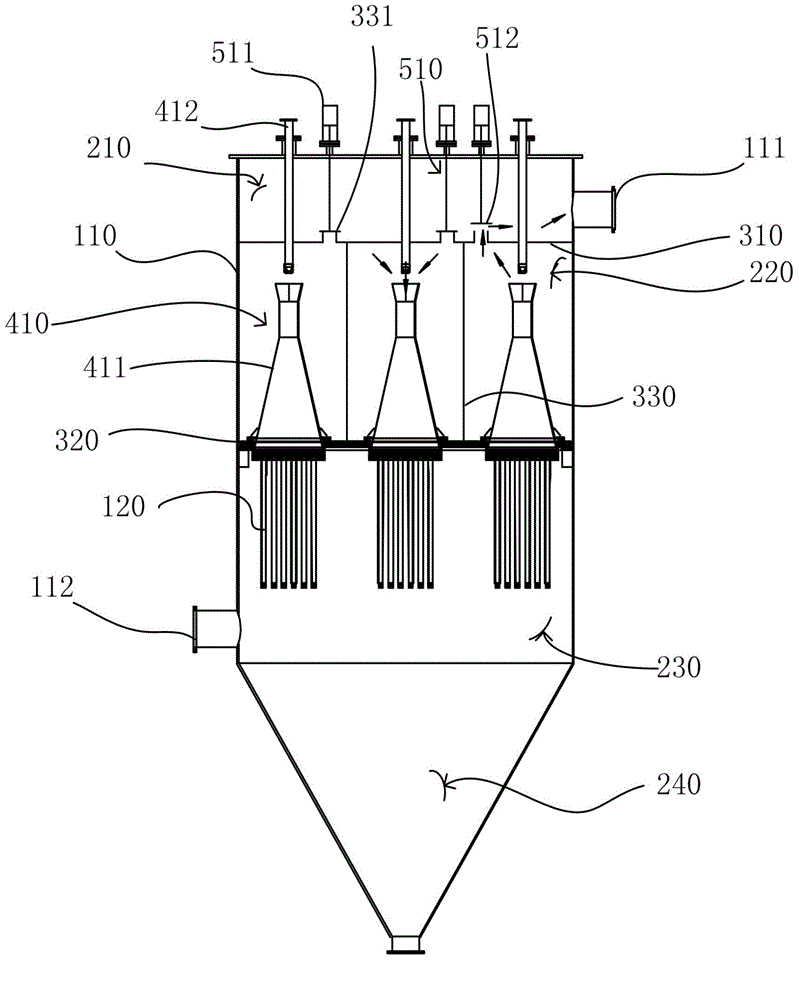

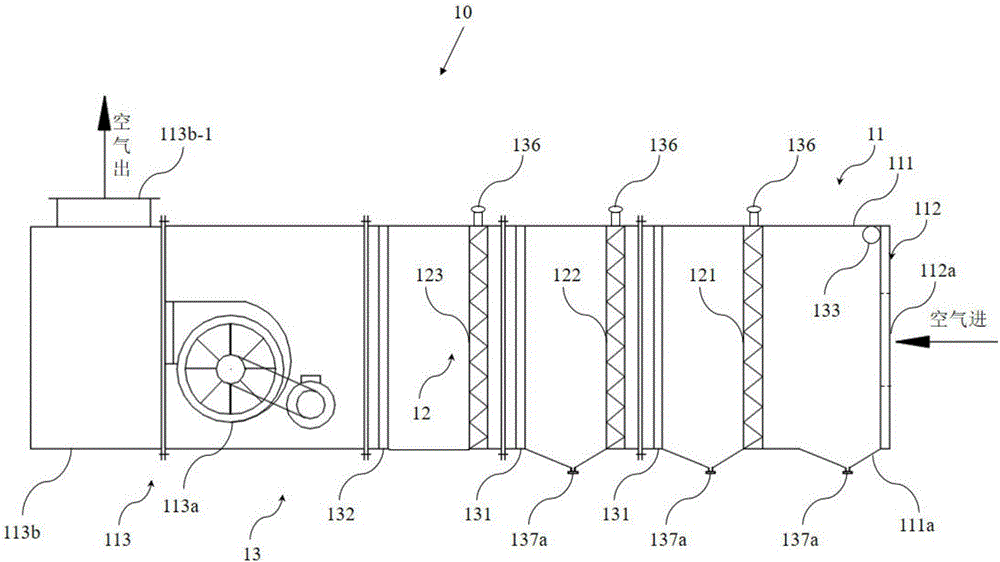

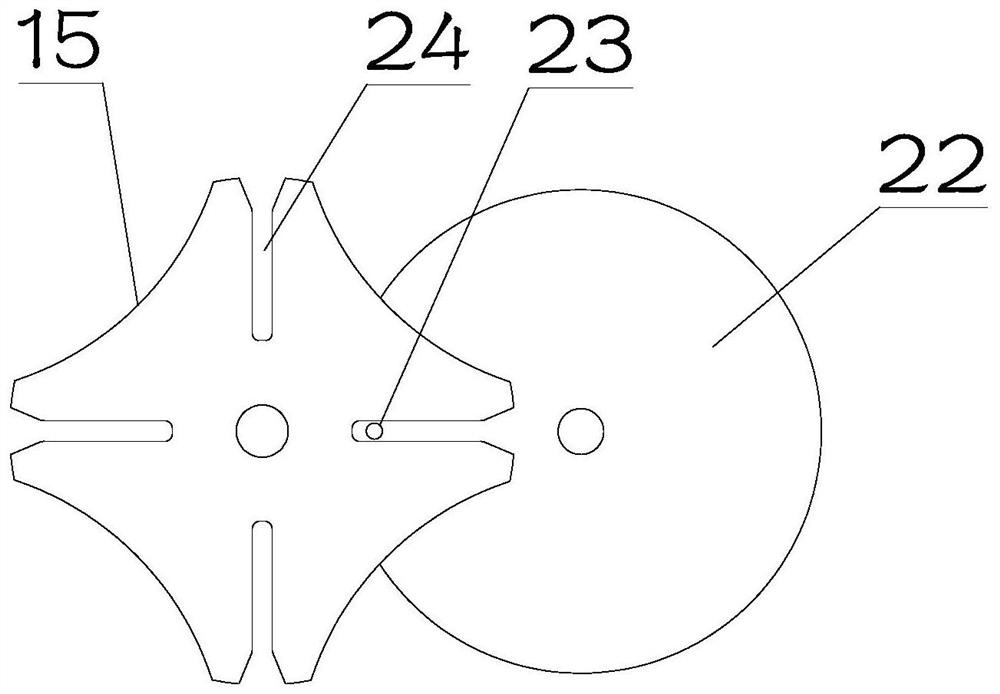

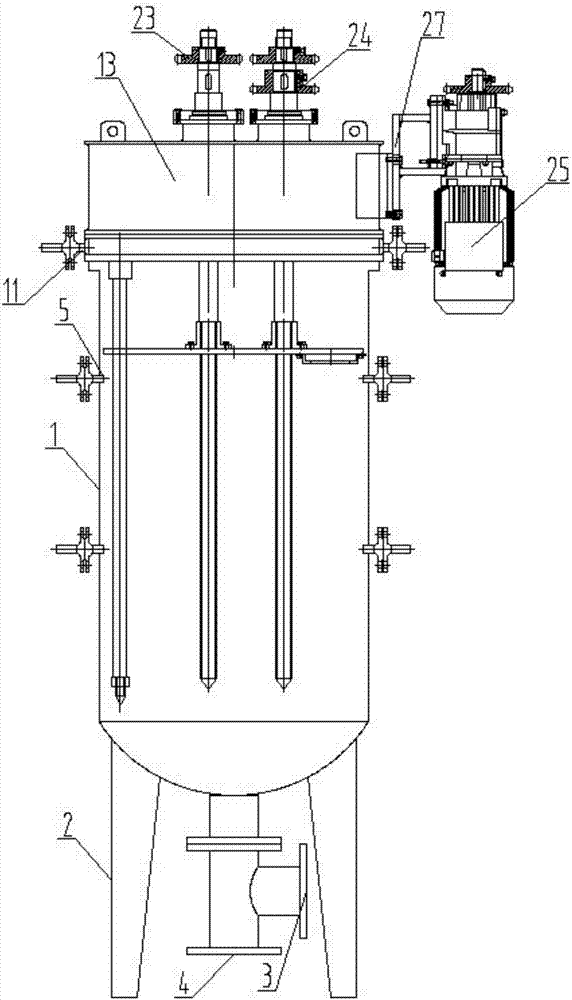

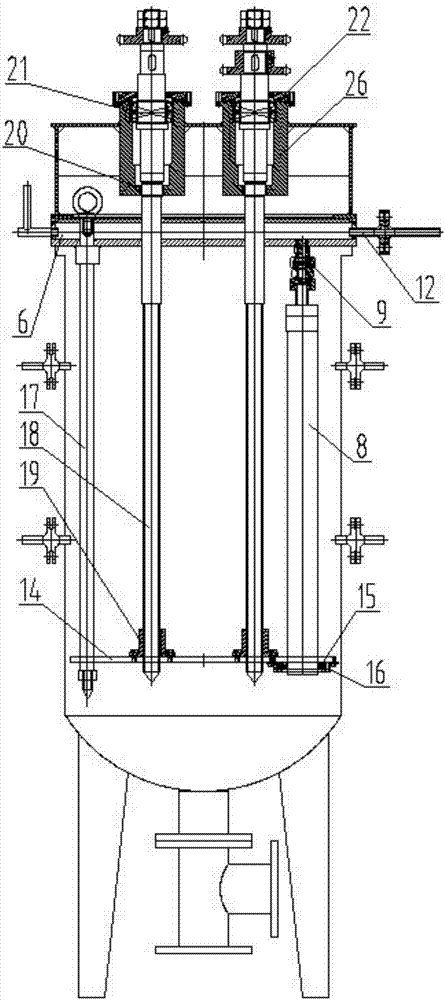

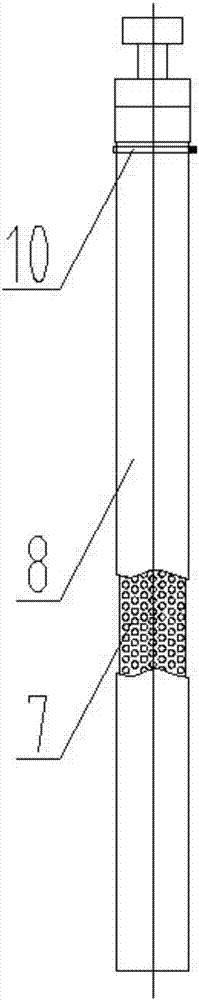

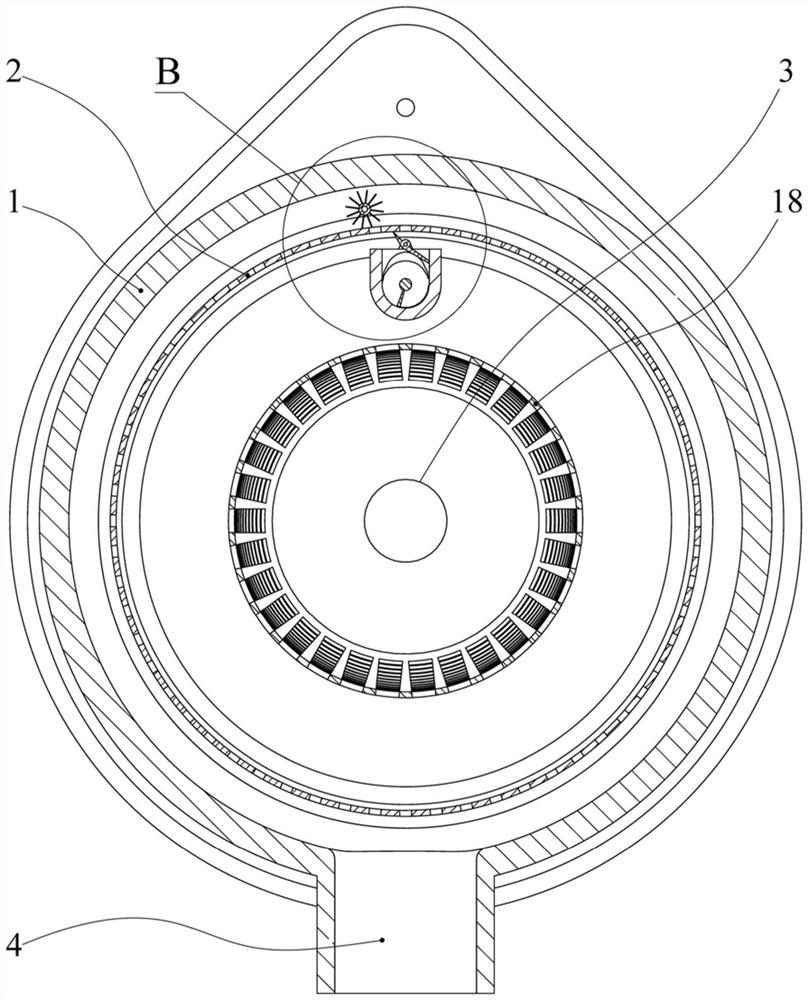

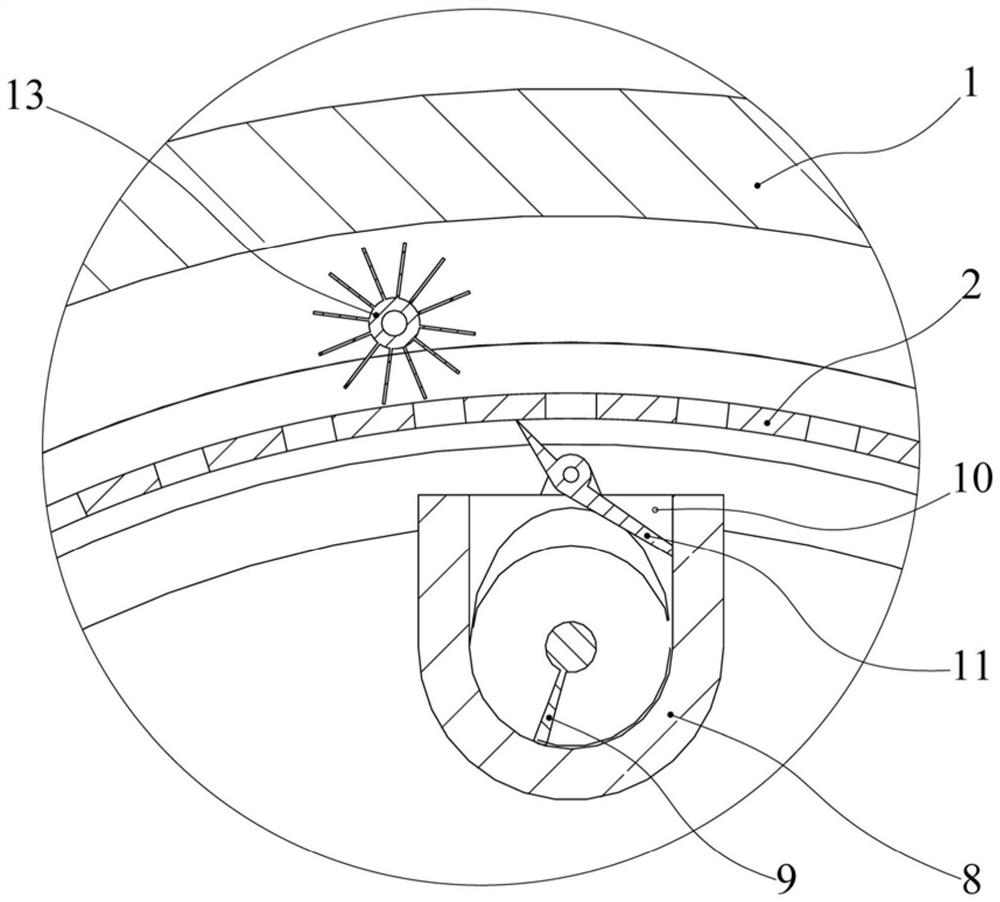

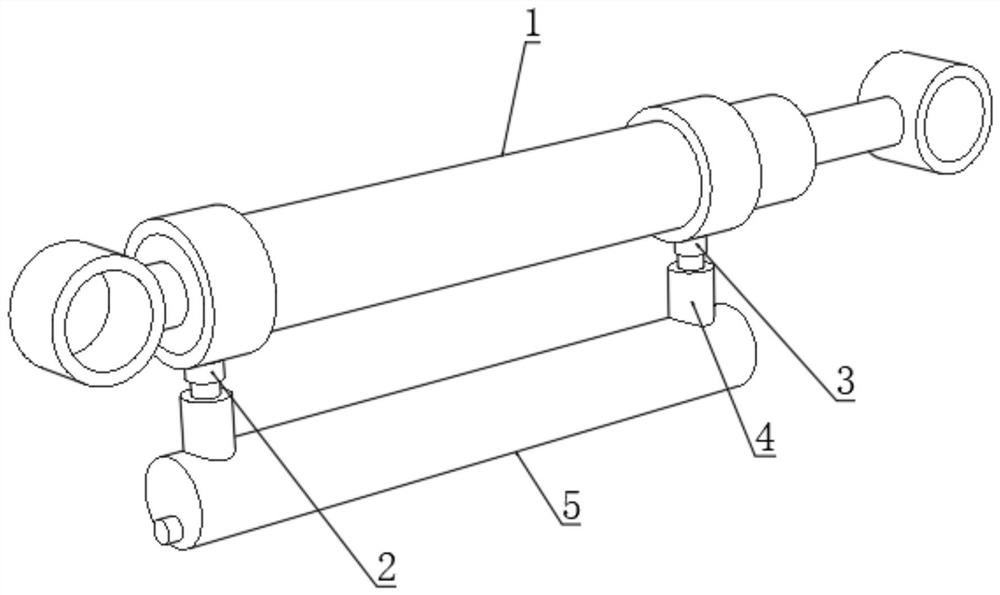

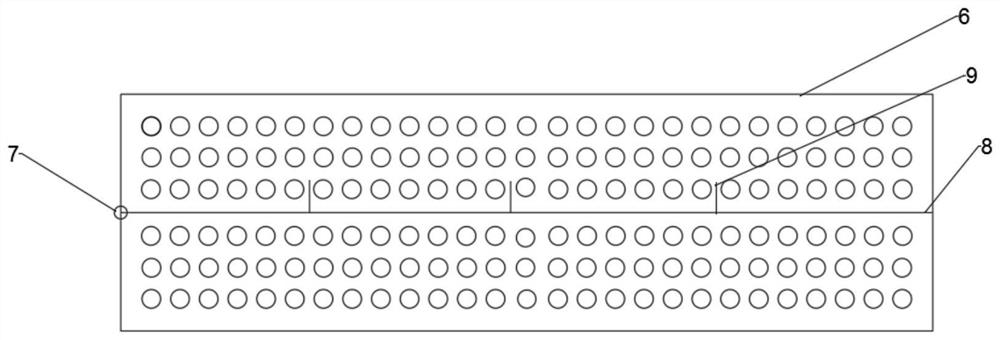

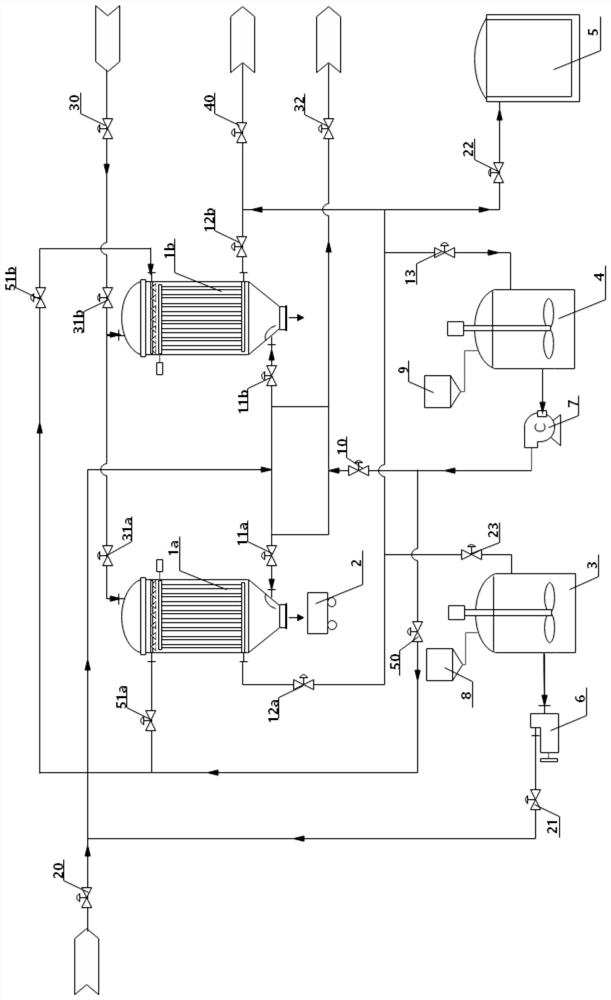

Gas filtering device

InactiveCN104785024AOvercome blowback resistanceContinuous filtrationDispersed particle filtrationProcess engineeringValve opening

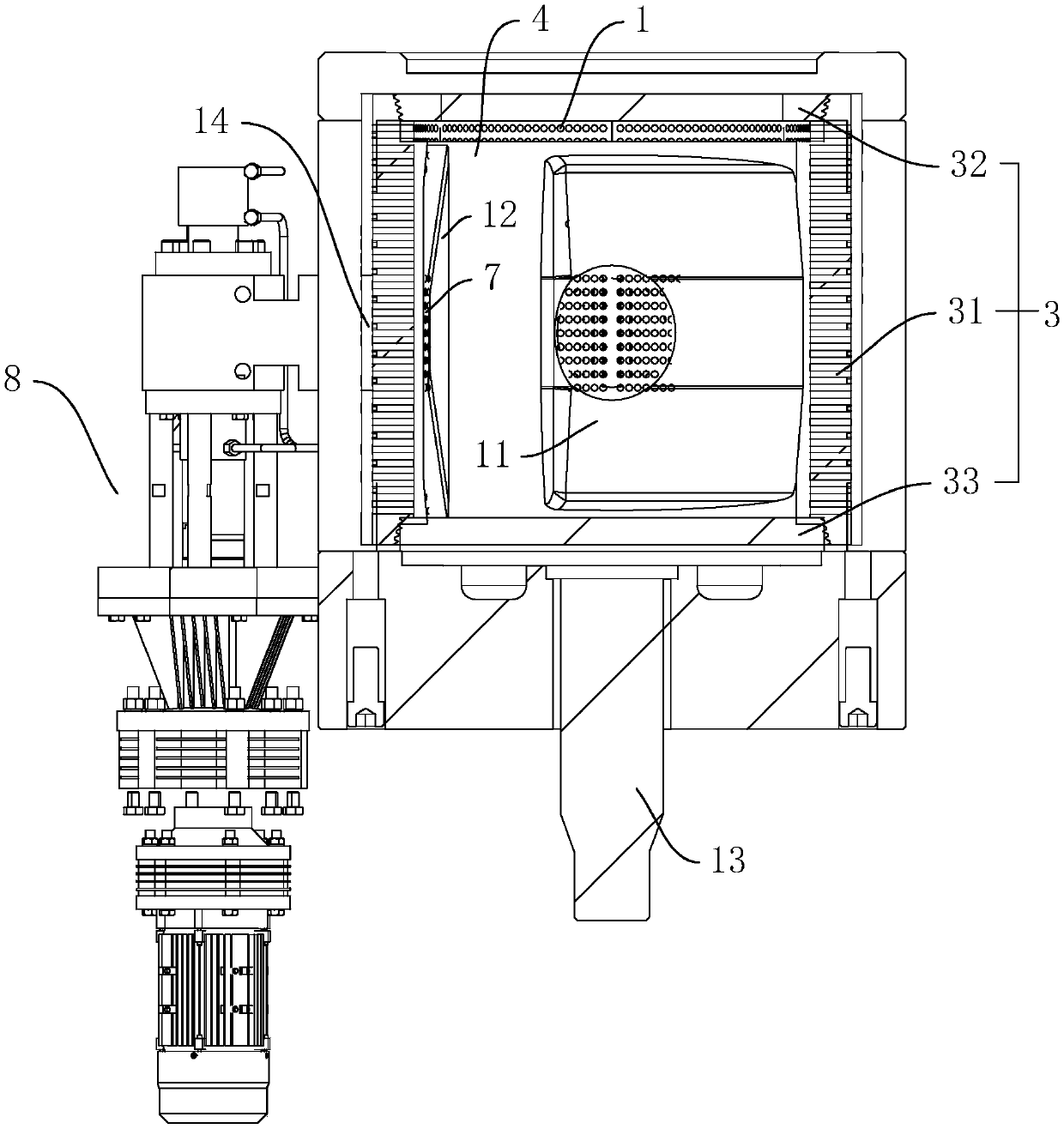

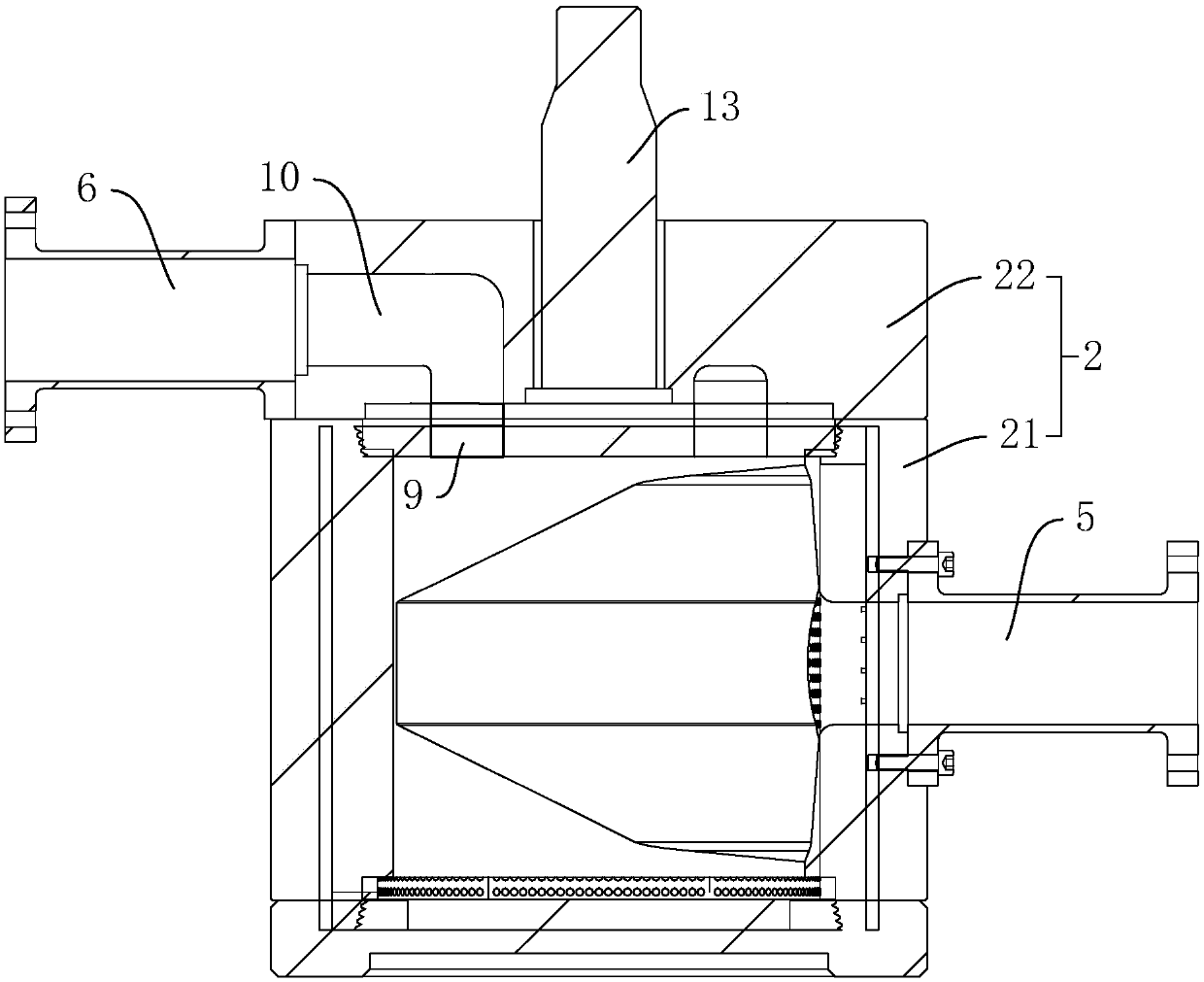

The invention discloses a gas filtering device. The gas filtering device comprises a filtering device shell and a pore plate, wherein the pore plate is arranged inside the filtering device shell and partitions the filtering device shell into a lower raw gas cavity and an upper pure gas cavity; at least two filter element groups are arranged below the pore plate; a back-blowing device connected with a back-blowing gas source is arranged above each filter element group; the pure gas cavity is partitioned into at least two independent chambers which are isolated from each other; at least one back-blowing device is arranged in each independent chamber; each independent chamber is provided with a valve opening used for discharging pure gas; a control mechanism used for controlling each valve opening to be opened and closed is arranged on the valve opening. The back-blowing resistance is overcome through the structure, and meanwhile, the gas filtering device keeps working continuously.

Owner:CHENGDU INTERMENT TECH

Treatment and recycling technology of white water in production of paper-making reconstituted tobacco

InactiveCN103172196AEmission reductionReduce pressure on environmental protectionMultistage water/sewage treatmentTreatment effectFiltration

The invention discloses a treatment and recycling technology of white water in the production of a paper-making reconstituted tobacco. The technology comprises the following steps of: flocculating the white water at a wet part in a production process of the reconstituted tobacco substrate by adding in a flocculating agent, carrying out precipitation pretreatment, filtering clear white water pumped from a clear white water tank by using a multi-disc filter with a self-purification function, causing the ultra-clear white water after the filtration to be collected in an ultra-clear white water tank for storage to prepare for recycling, and returning the automatically discharged solid content in the filtration process to a tapered sedimentation tank. The technology is very applicable to the continuous treatment of the white water in the production process of the reconstituted tobacco substrate, free from back flush, low in treatment cost, good in treatment effect, and 70-80% in solid content removal rate, the ultra-clear white water after the treatment can completely replace clear water to be reused for screen washing, low-pressure spraying and screen edge sealing, the removed solid content dreg can be added into a slurry according to a proportion, waste water drain is reduced, environment protection pressure is relived, raw materials are saved, and economic benefit is obvious.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

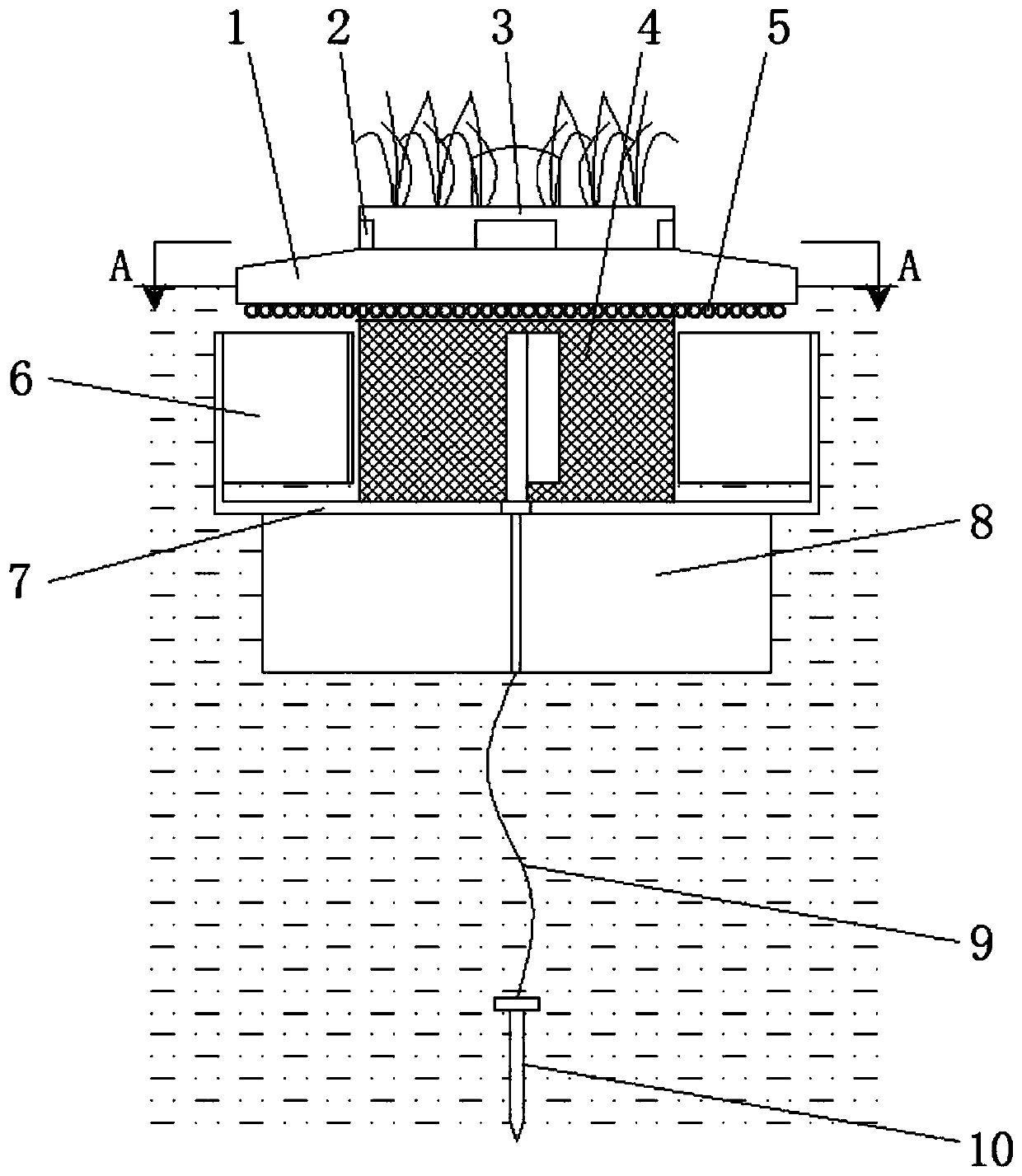

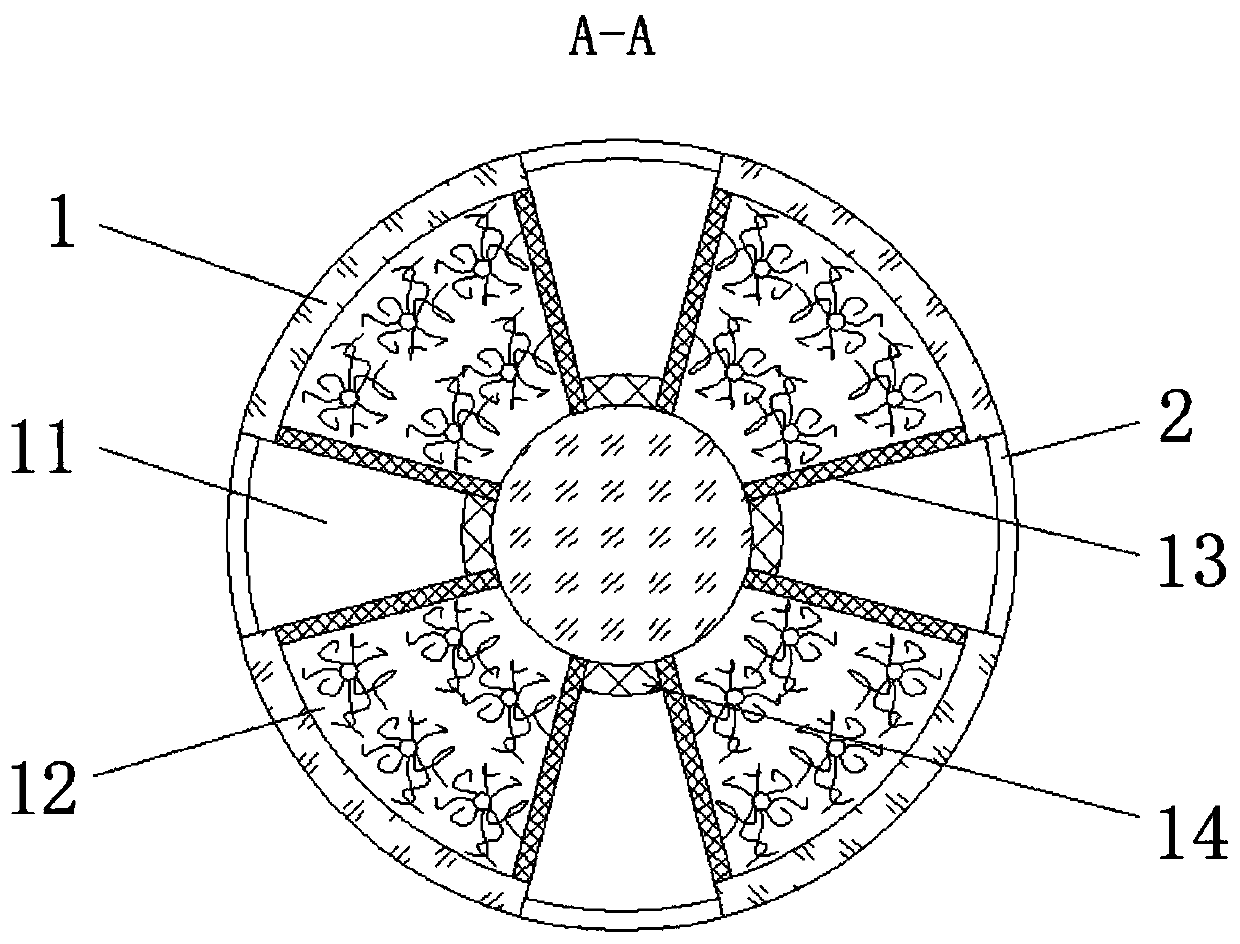

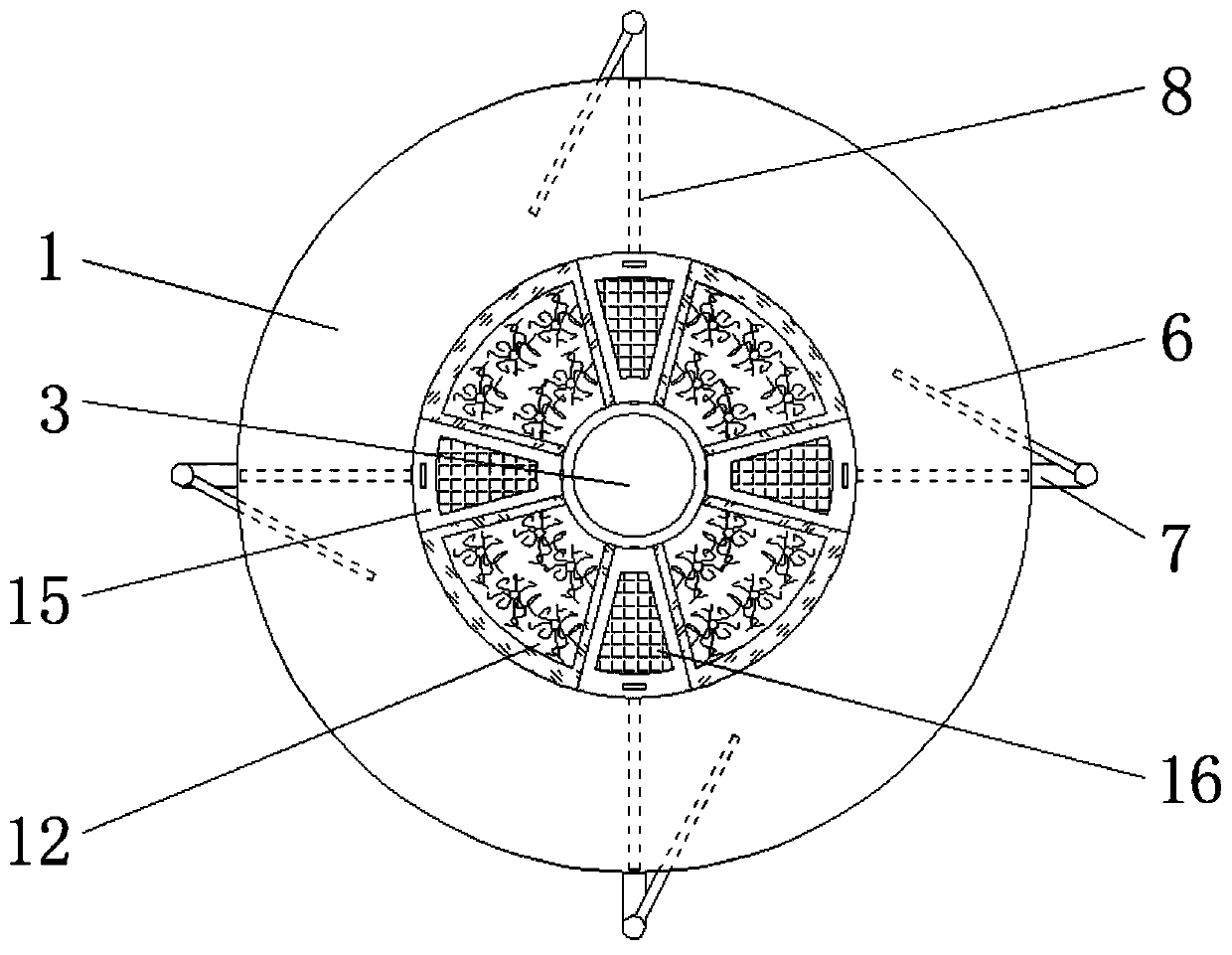

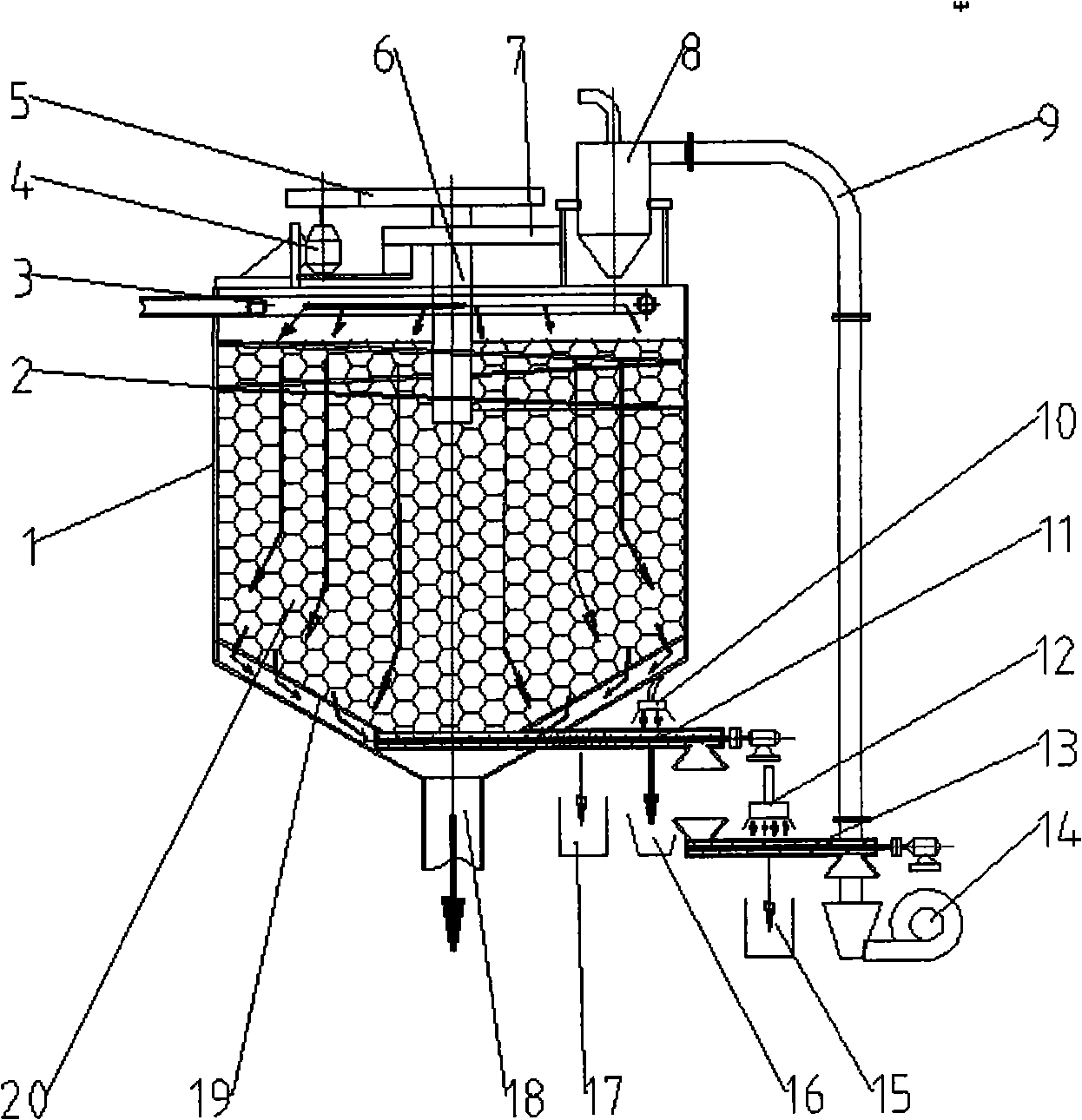

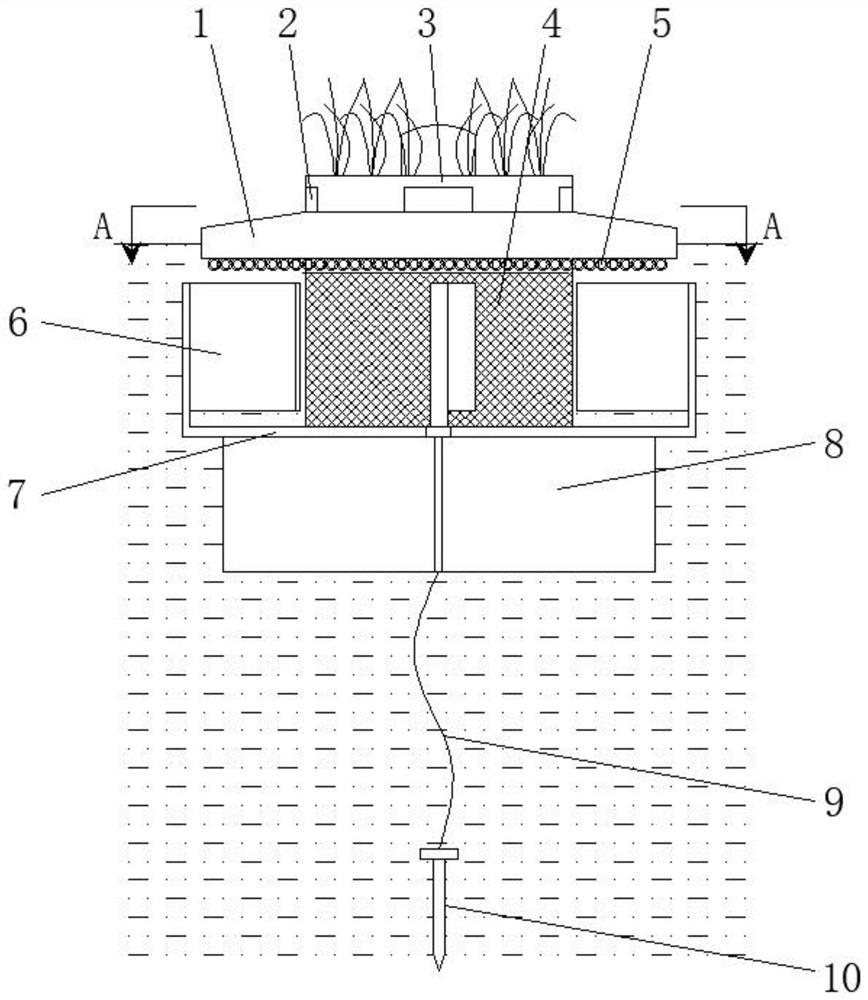

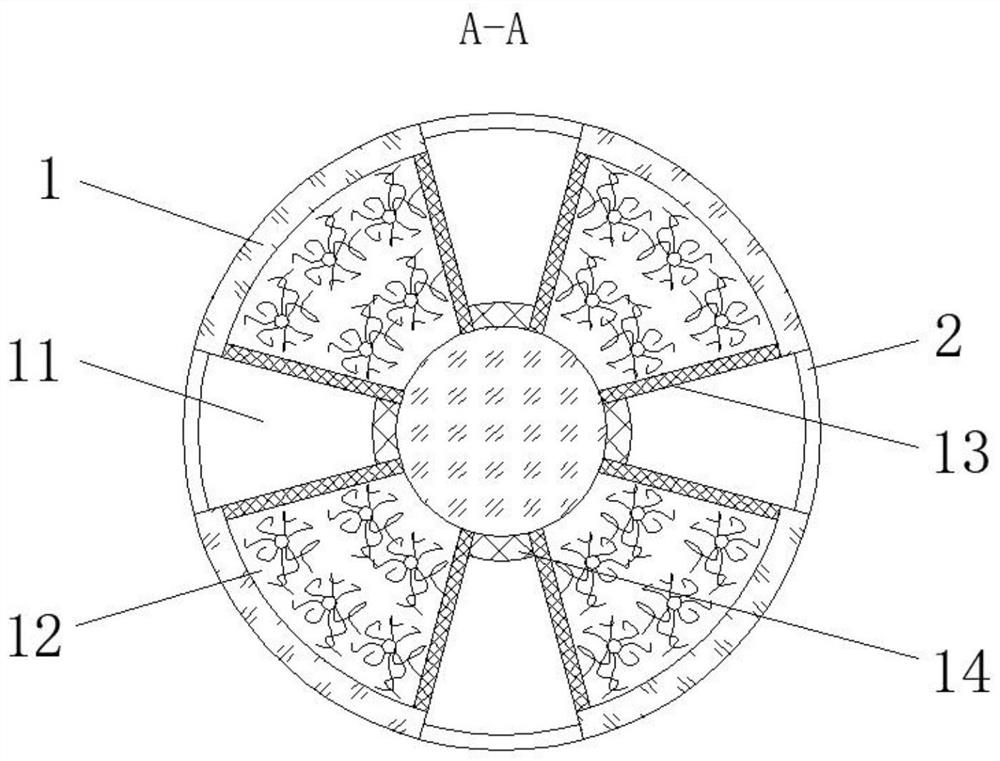

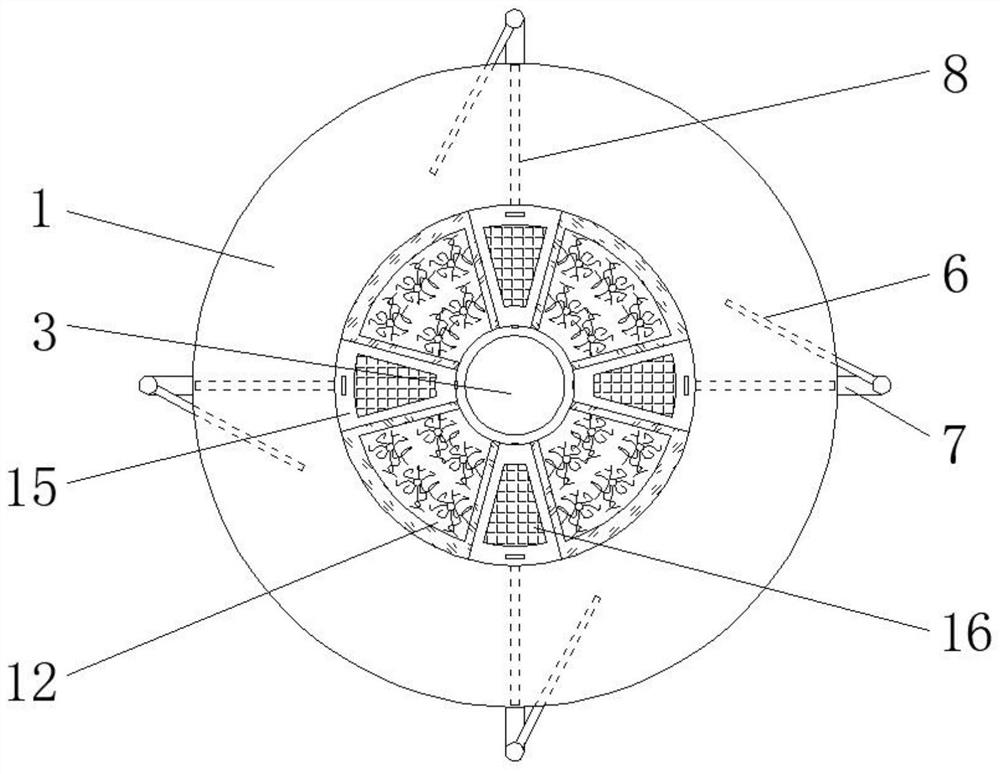

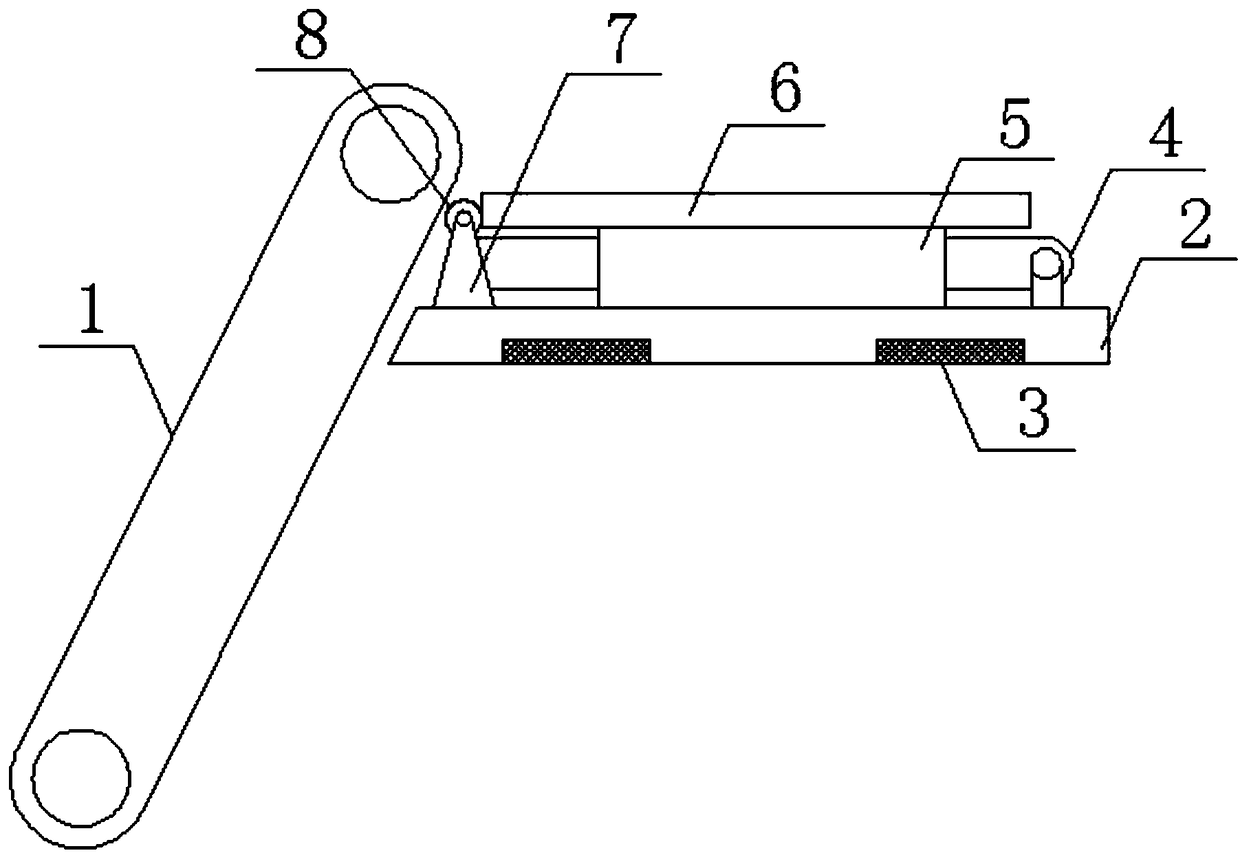

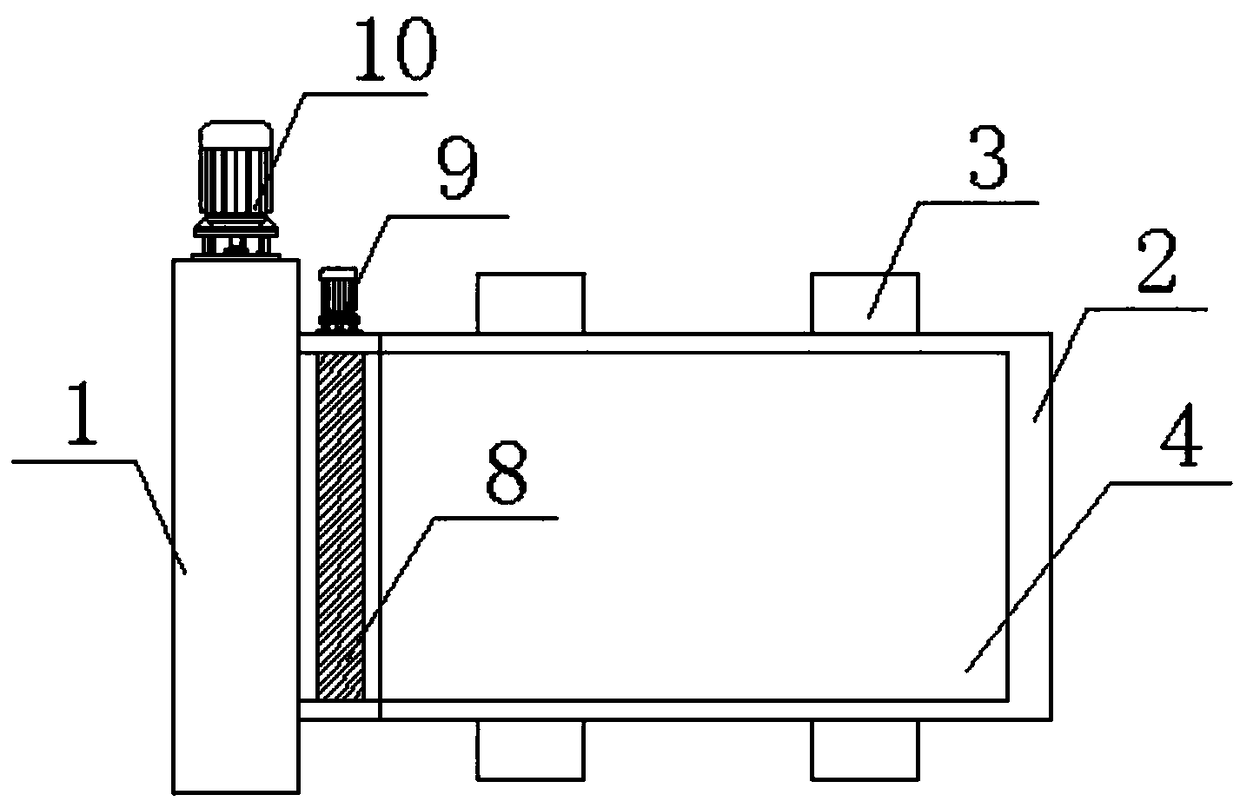

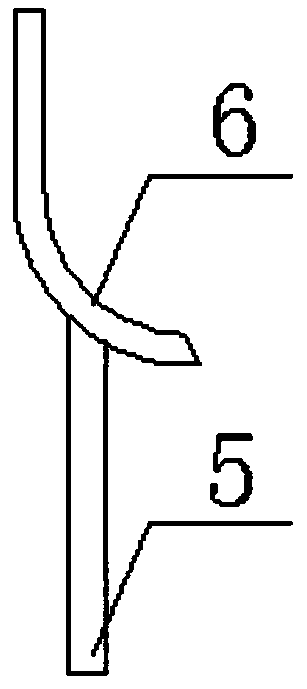

Ecological floating island for remediation and treatment of black and odorous water

ActiveCN110282745APurify the surrounding environmentImprove flotationSpecific water treatment objectivesWater/sewage treatment apparatusSewageDrive motor

The invention discloses an ecological floating island for remediation and treatment of black and odorous water. The ecological floating island comprises a floating base, a net-shaped cylinder base, a floating ball, a balance frame, a steel wire rope and a fixing rivet, the net-shaped cylinder base is welded with the bottom of a purification base, and the floating base is fixed to the junction of the purification base and the net-shaped cylinder base and located on the outer side wall of the purification base; a driving motor is installed in a top protrusion of the purification base, and one end of a rotary shaft extends to the bottom of the net-shaped cylinder base and is provided with a rotary rack; the balance frame is installed at the bottom of the rotary rack, the steel wire rope is connected with the center of the bottom of the balance frame, and the fixing rivet is fixed to one end of the steel wire rope. According to the ecological floating island for remediation and treatment of the black and odorous water, by installing the floating base, the purification base and the floating ball and forming ecological planting grooves, the black and odorous water can be effectively adjusted through the rhizomes of aquatic plants, floating objects on the surface of the water can be effectively collected through the floating island, and the area of the purified water is increased. The problems are solved that a traditional sewage purification device is single in function, small in purification area, long in treatment time, low in purification speed, high in maintenance cost and the like.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

Preparation method of polytetra fluorethylene hydrophilic micro filtering membrane

InactiveCN1785490ANo initial filtration periodHigh filtration precisionSemi-permeable membranesPolyvinyl alcoholTeflon membrane

A hydrophilic microfiltering teflon membrane is prepared from teflon resin (95-100 mass%) and PVA (0-5) through mixing, bidirectional stretching to become membrane, fixing its shape at 270-500 deg.C and activiating. It has high hydrophilicity and water permeability.

Owner:LISHUI UNIV

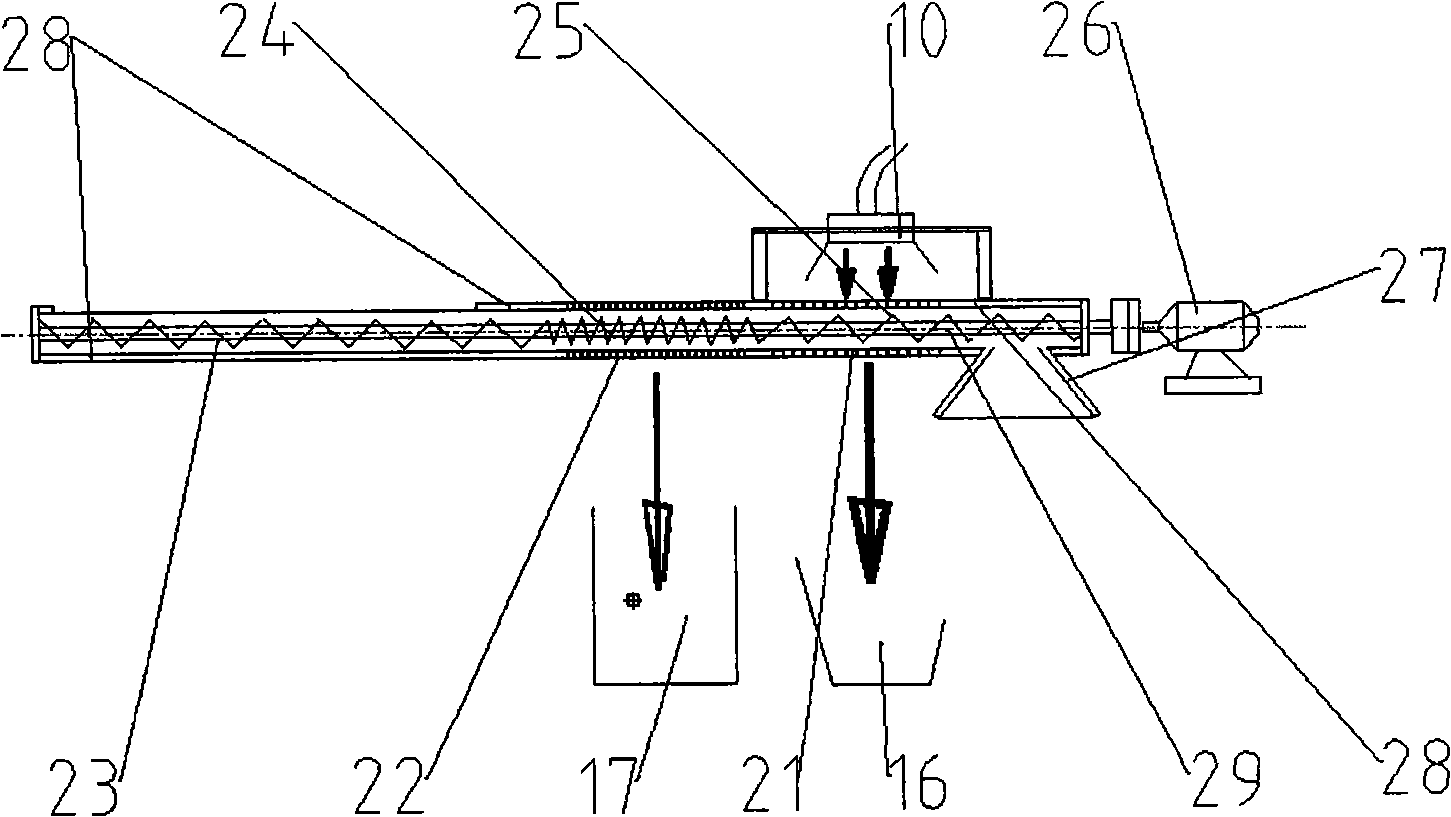

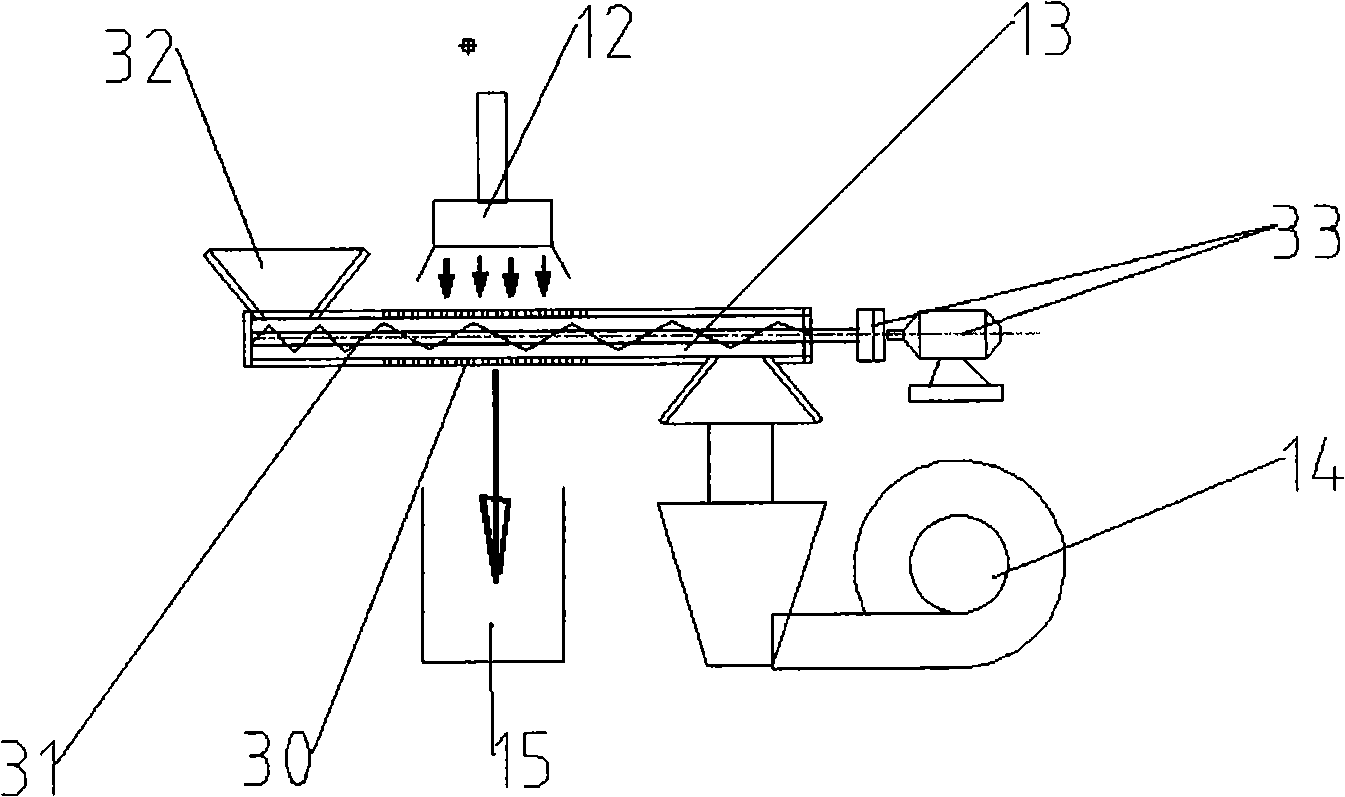

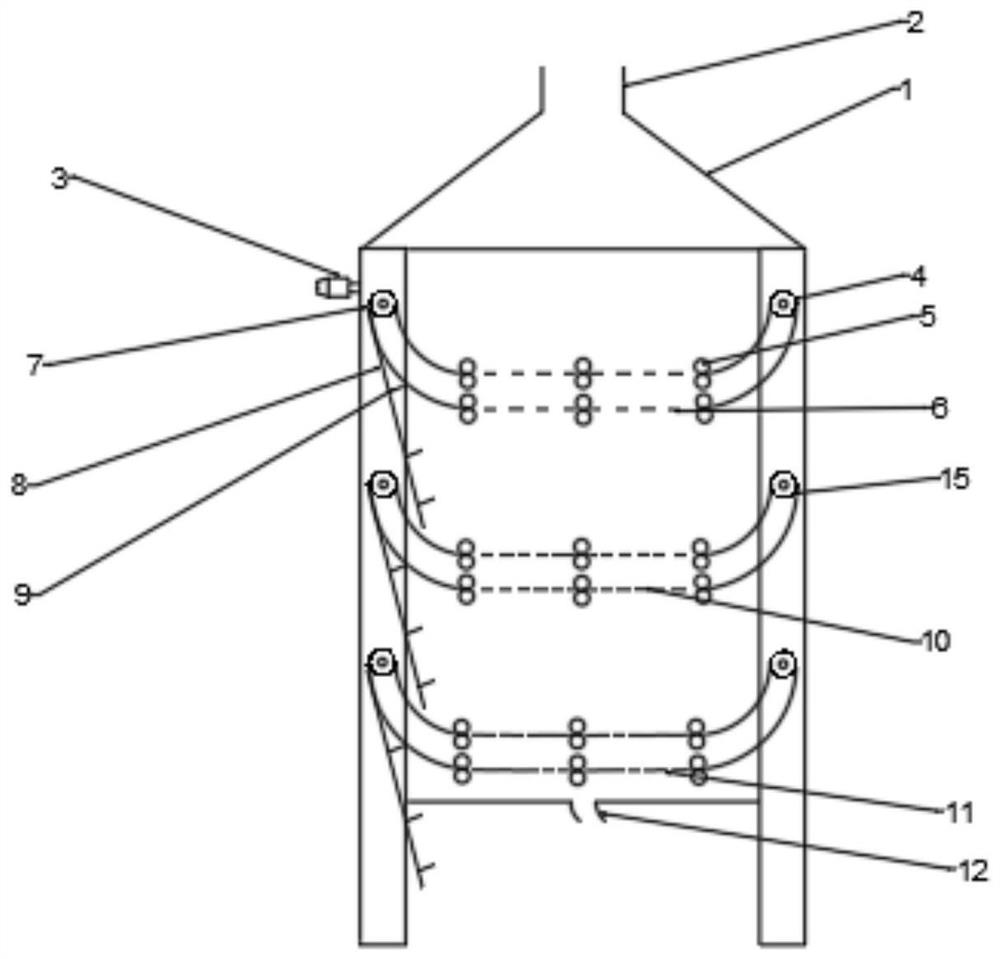

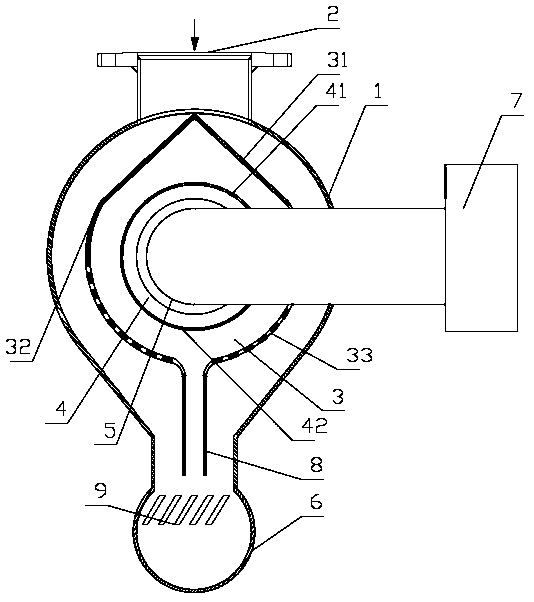

Continuous fibrous globule filter and its filtering method

InactiveCN101306268AContinuous filtrationWell concentratedLoose filtering material filtersGravity filtersAutomatic controlAirflow

A continuous fiber ball filtering machine and a filtering method belong to the technology filed of sewage filtration. The continuous fiber ball filtering machine comprises a continuous fiber ball filtering machine main body, a fiber ball cleaning system and a fiber ball sending-back system. A feed inlet of the fiber ball cleaning system is welded at the lower part of the continuous fiber ball filtering machine main body, the feed inlet of the fiber ball sending-back system needs to be aligned with a discharge outlet of the fiber ball cleaning system, and a discharger of the fiber ball sending-back system is arranged at the upper end surface of the continuous fiber ball filtering machine main body. The continuous fiber ball filtering machine has the advantages that the filter has the independent filtering ball cleaning system and the sending-back system, thereby realizing the continuous filtration; a step of dirty filtering ball squeezing is added, most of the sewage in the filtering ball can be squeezed in the step; a step of air flow cleaning is added, the sludge blown by the air flow is easier to concentrate in the situation that the sewage in the filtering ball is squeezed out, the air flow is used for carrying out the flush after the squeezing and the air flow cleaning, thereby reducing the water consumption for back flush; and the automatic control is easy to realize.

Owner:北京市农业机械研究所有限公司

Flushing-free multistage high efficiency filter

InactiveCN102824774AEasy to passEfficient removalStationary filtering element filtersWater savingWater flow

The invention provides a flushing-free multistage high efficiency filter, which comprises a casing with a liquid inlet, a liquid outlet and a water outlet, an inner filter membrane column and an outer filter membrane column are provided in the casing, an inner filter water outlet channel and an outer filter water outlet channel are respectively provided at the inner side of the inner filter membrane column and the outer side of the outer filter membrane column, an inner water output pipe with a through hole which is characterized in that two ends of the inner water output pipe extend outside the casing is provided in the inner filter water outlet channel, the inner filter water outlet channel and the water outlet on the casing are communicated, a rotating brush roller with an inner brush and an outer brush is provided between the inner filter membrane column and the outer filter membrane, a first end head with a through hole is provided at one end of the rotating brush roller, a second end head with the through hole is provided at the other end, the first end head and the second end head are connected to the inner outlet pipe through a bearing and a bearing pedestal, wherein the first end head or the second end head are connected to a power wheel through the bearing pedestal. According to the invention, the materials blocked on the filter membrane column can be continuously removed, the water flow is increased, the backwashing on the filter membrane column is not required, thereby the filtering efficiency and the filtration yield can be increased by one time, and the flushing-free multistage high efficiency filter has the advantages of simple structure, reliable operation, water saving and consumption reduction, no environmental pollution and the like.

Owner:李曦

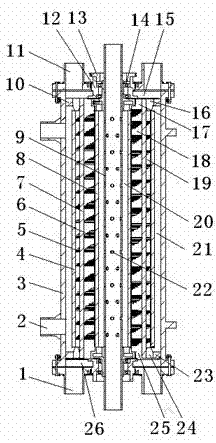

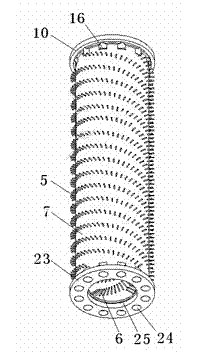

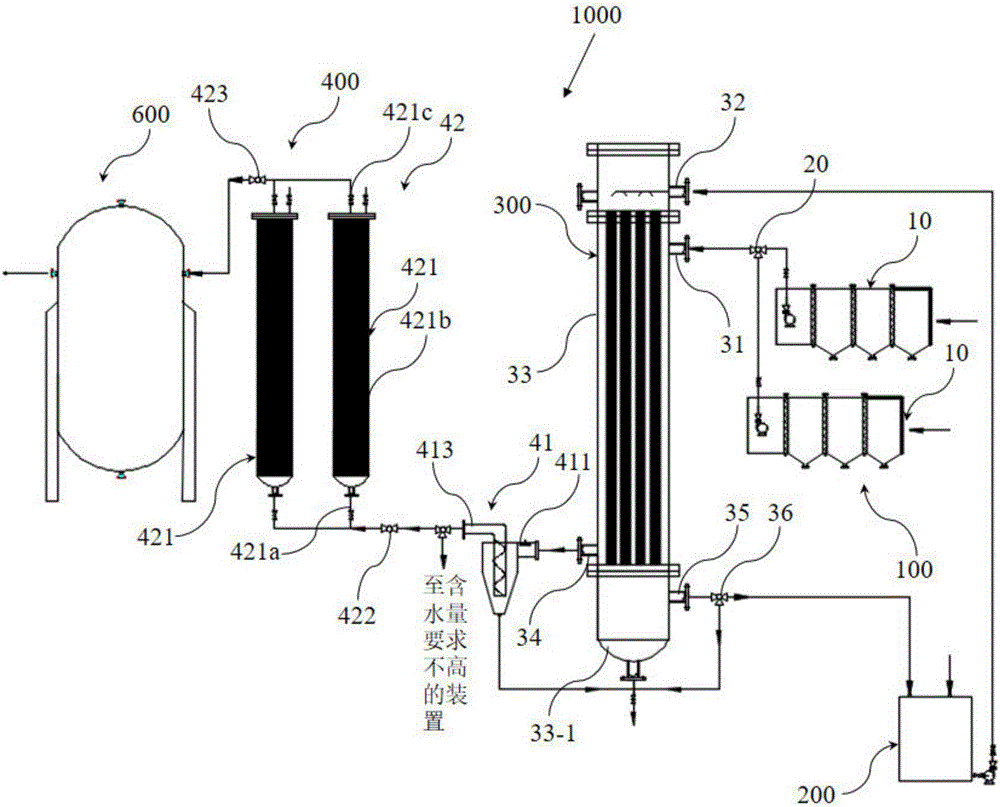

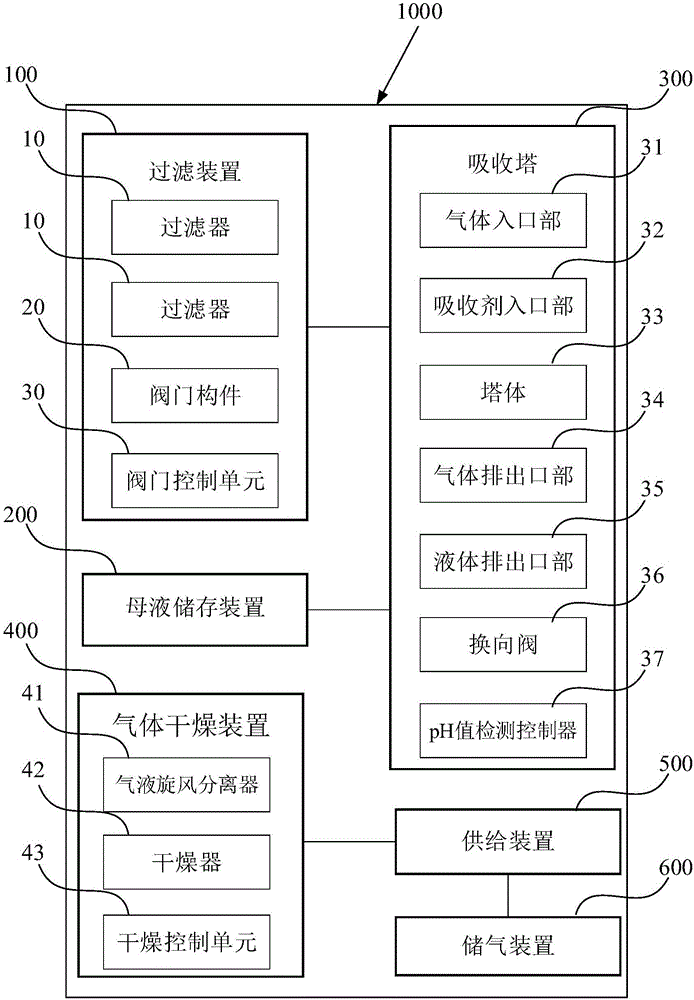

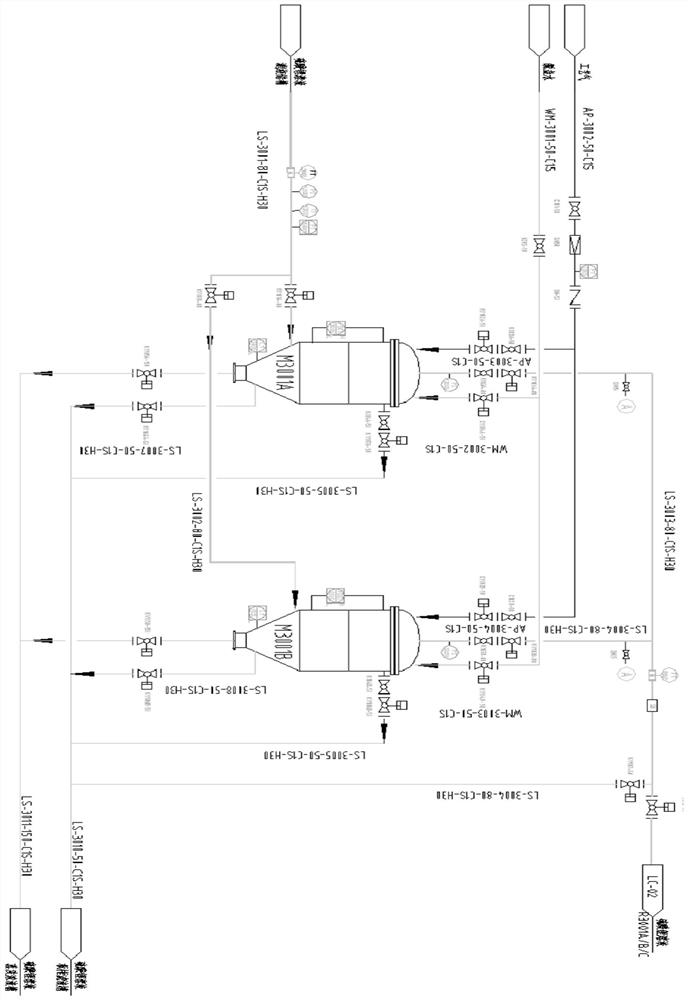

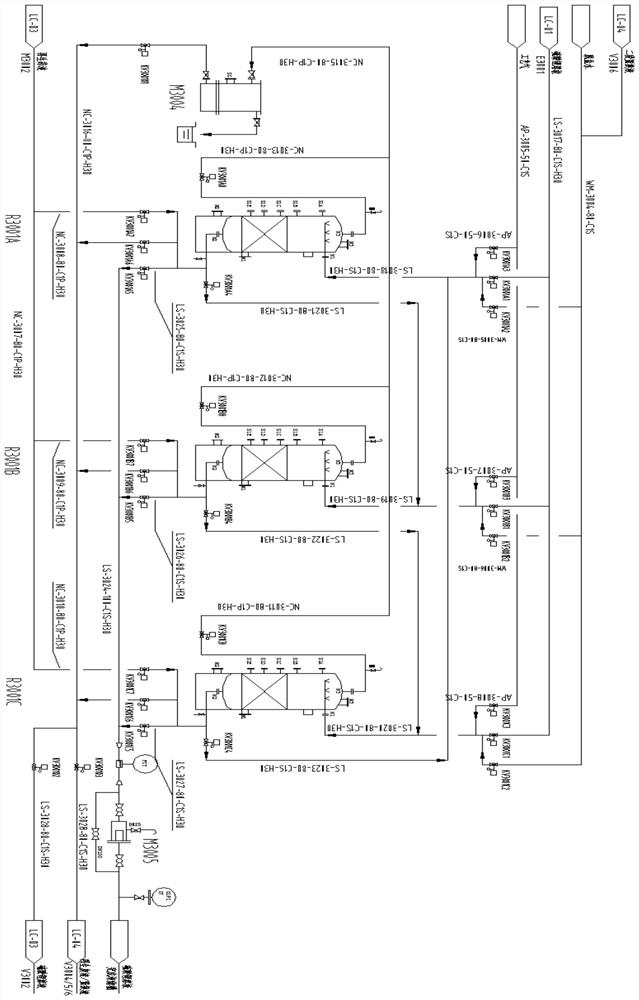

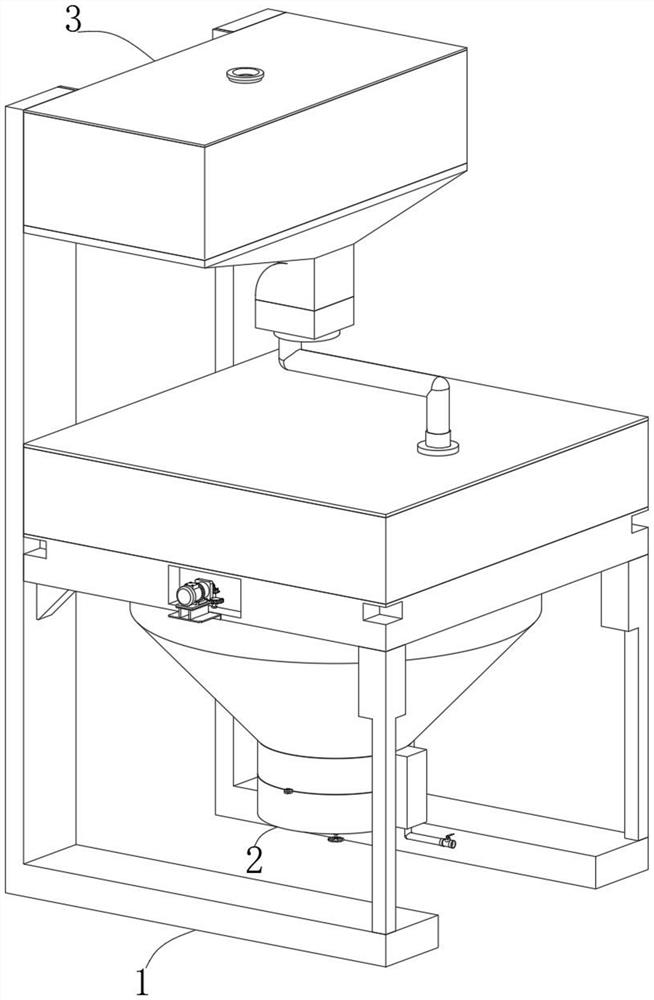

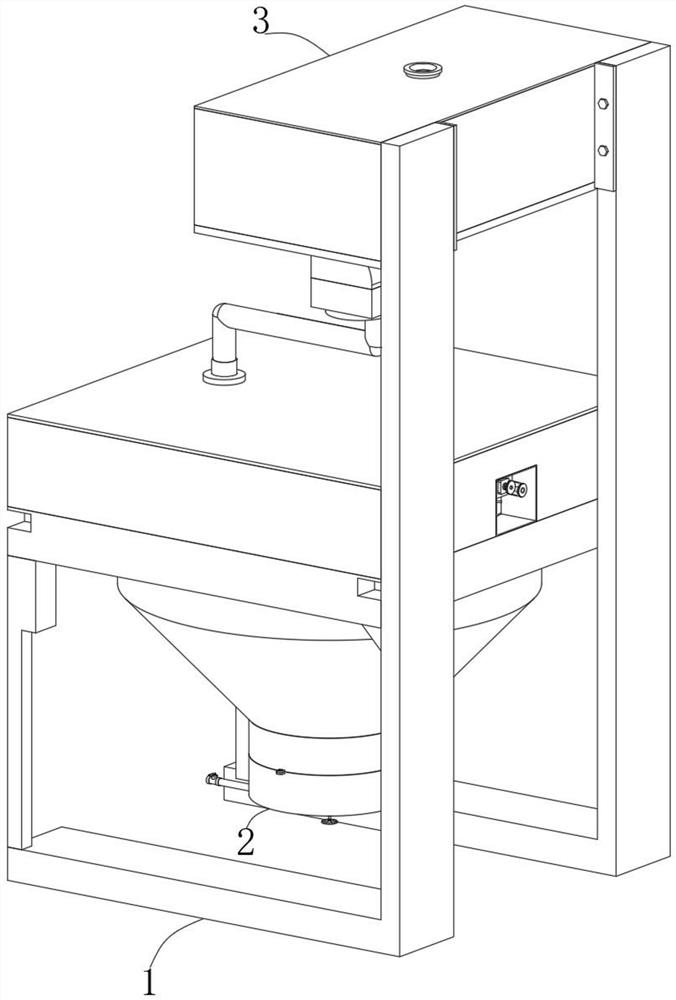

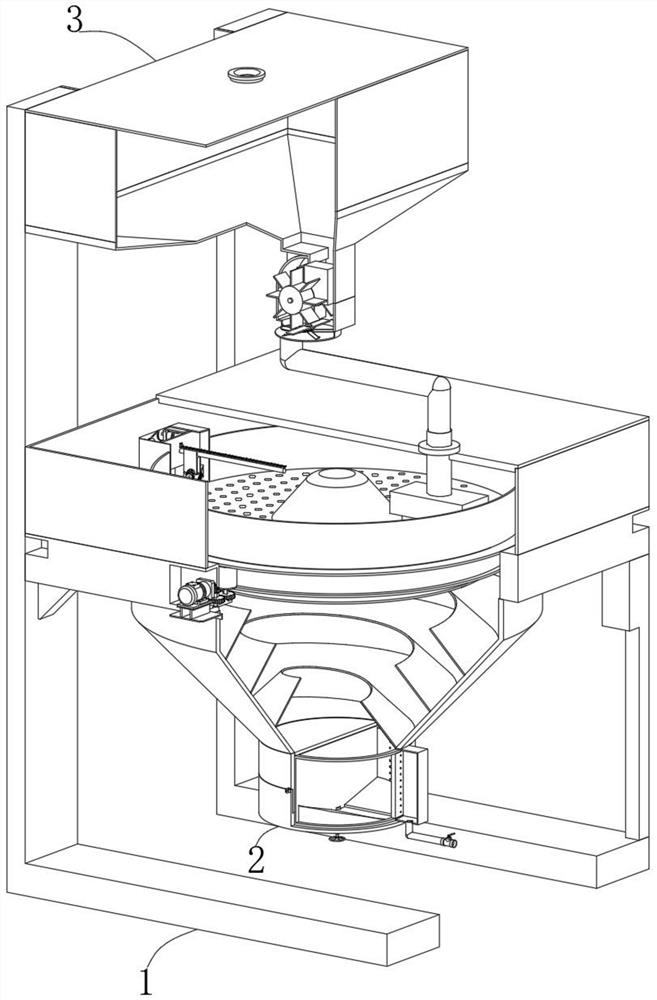

Automatic system for preparing lithium hydroxide

ActiveCN106348318AReduce manufacturing costFully absorbedLithium oxides/hydroxidesParticulatesLithium hydroxide

The invention provides an automatic system for preparing lithium hydroxide with low preparation cost. The automatic system for preparing lithium hydroxide, provided by the invention, comprises a preparation subsystem and is characterized by further comprising a protective air supply subsystem, a filtering device, a mother liquor storage device, an absorption tower, an air drying device and a feeding device, wherein the protective air supply subsystem is used for removing carbon dioxide from air so as to supply air free from carbon dioxide as protection air to the preparation technology of lithium hydroxide; the filtering device is used for filtering grains from air and comprises at least two filters, a valve component and a valve control unit; the remained lithium hydroxide mother liquor after crystal is separated from a concentrating crystallizing device is stored in the mother liquor storage device; the absorption tower introduces the lithium hydroxide mother liquor as an absorption agent for absorbing carbon dioxide in the filtered air so as to obtain the air free from carbon dioxide; the air drying device is used for drying the air free from carbon dioxide and obtaining the protective air; the feeding device is communicated with the air drying device and is used for feeding the protective air to the preparation subsystem.

Owner:JINGMEN GEM NEW MATERIAL

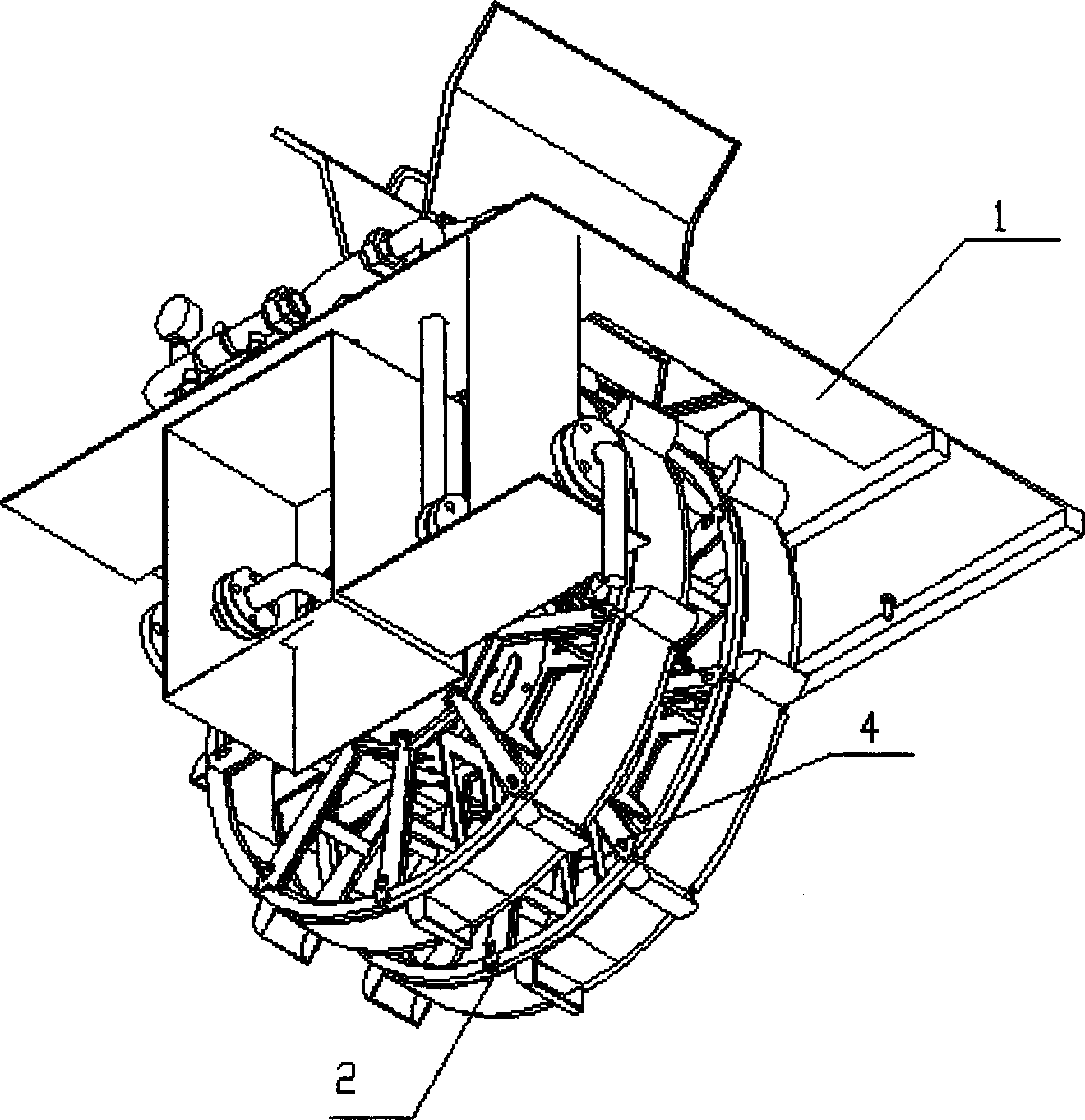

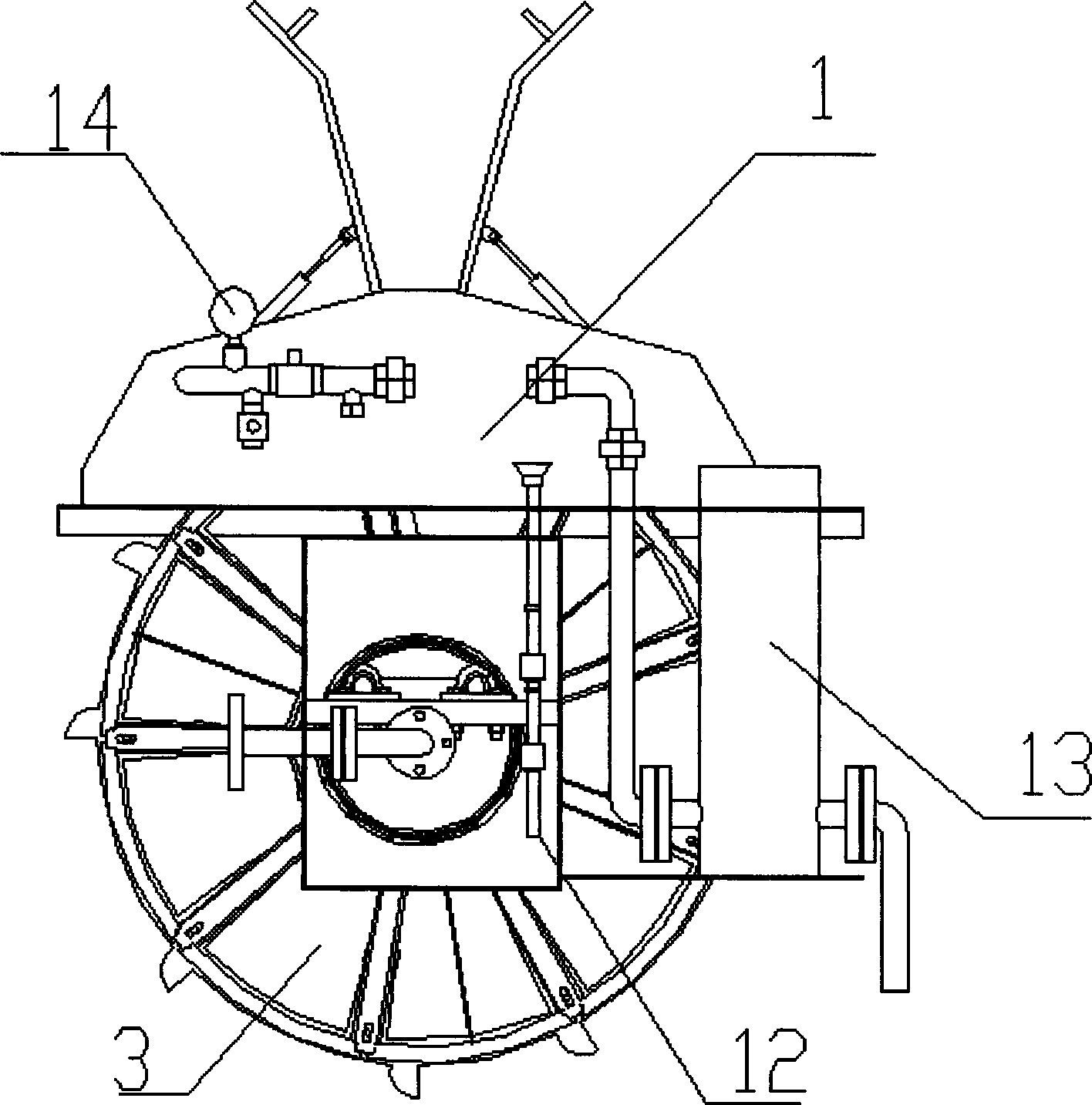

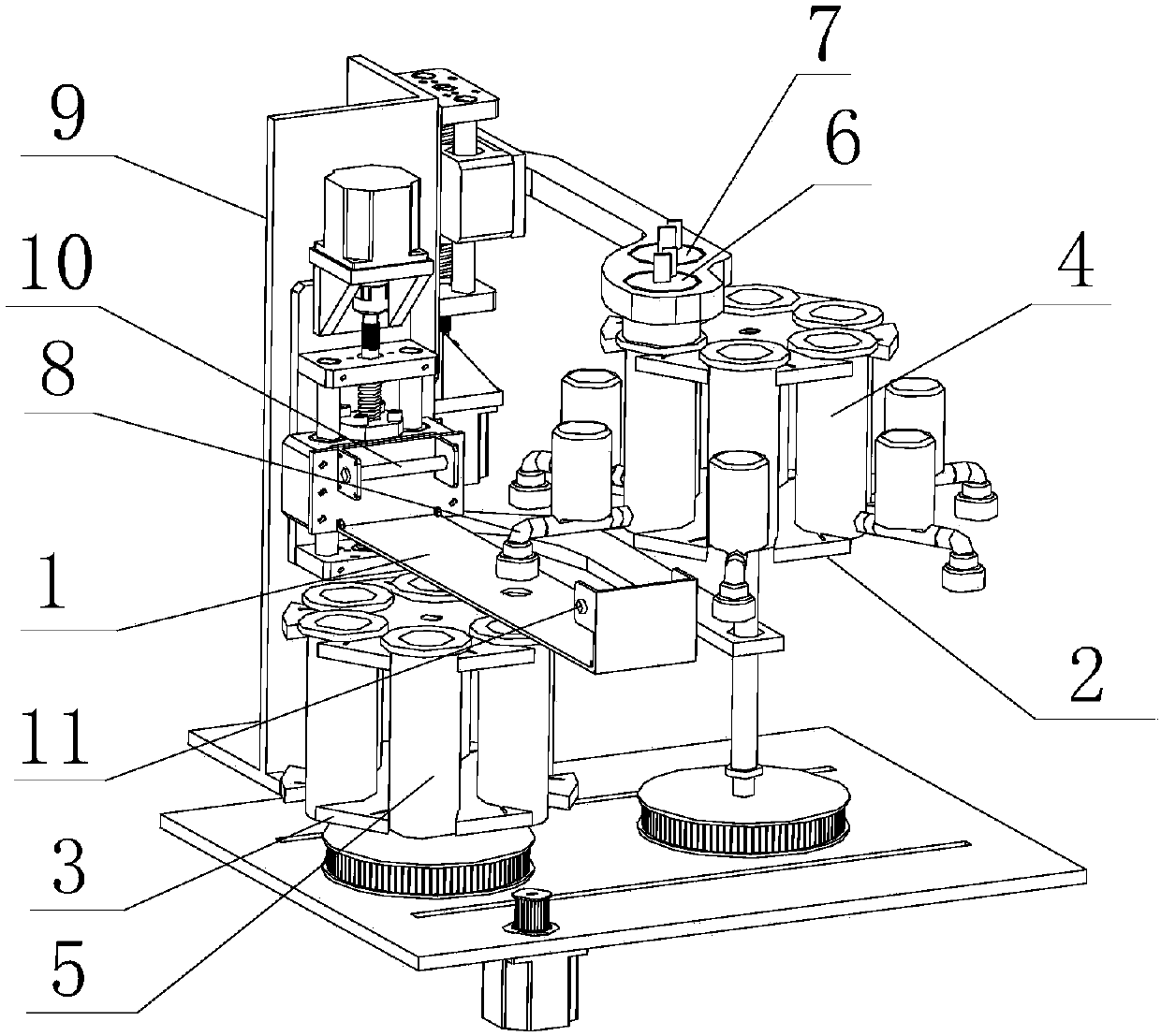

Turntable filter

InactiveCN103230697AUnattendedReduce filter loadMoving filtering element filtersAutomatic controlSprayer

The invention discloses a turntable filter which comprises a main framework, a core filtering system filtering net, a driving system, a backwash system and an automatic control system, wherein the main framework consists of a shell, a central water inlet pipe, a roller, a toothed gear, a rotating bearing, a central drum and a sealing piece; the driving system comprises a driving motor, a driving gear and a roller supporting wheel; and the backwash system comprises a reverse cleaning pump, a backwash sprayer, a flushing water pipe, a nozzle system, a sewage collecting groove and a blow-off line. Compared with the traditional process, the turntable filter has the advantages that the civil engineering such as a blowing room, a lifting pump room, a chlorination room, a clean-water reservoir and a settling pond are saved, the occupied area is small, and the occupied area of 10000-tonnage water is 15 square meters only and is only 1 / 7 to 1 / 6 of the area occupied by the traditional process, so that the maintenance and repair of the equipment are simple and convenient, the operating automation degree is quite high, special care is not required, and the labor intensity of workers and the maintenance cost are greatly reduced.

Owner:深圳市龙成科技有限公司

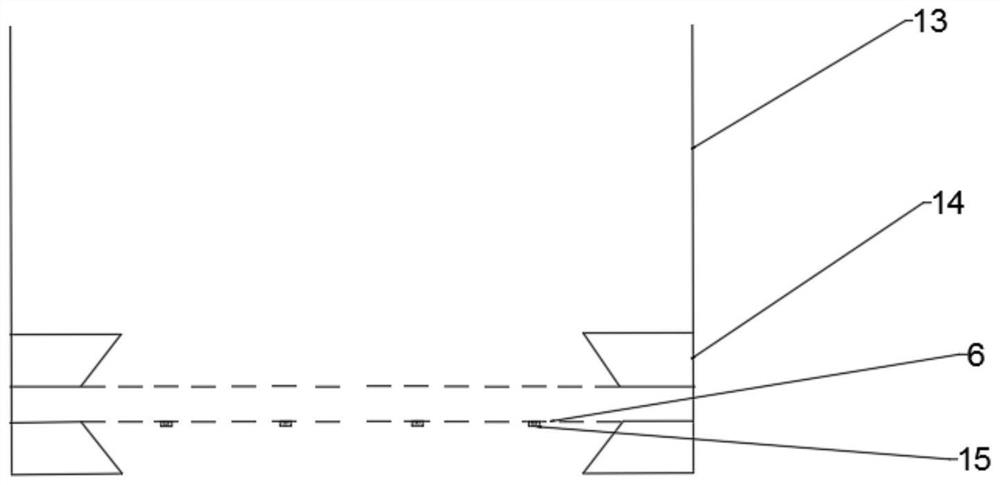

Removal of ammonia in urea finishing

Owner:STAMICARBON BV

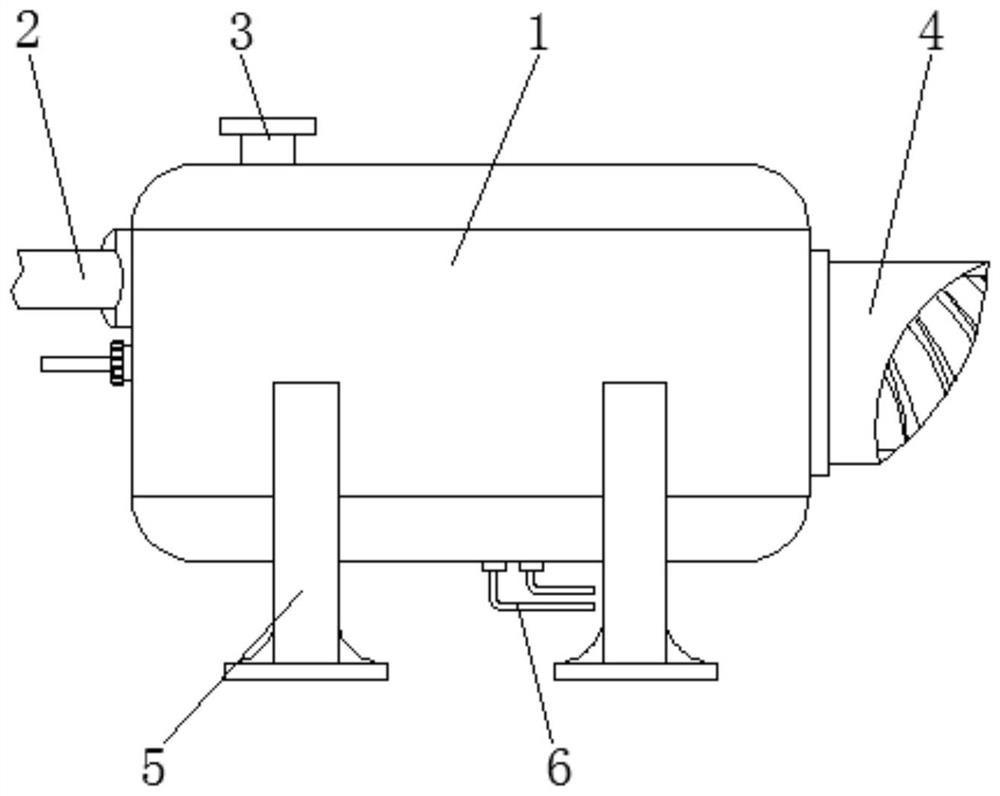

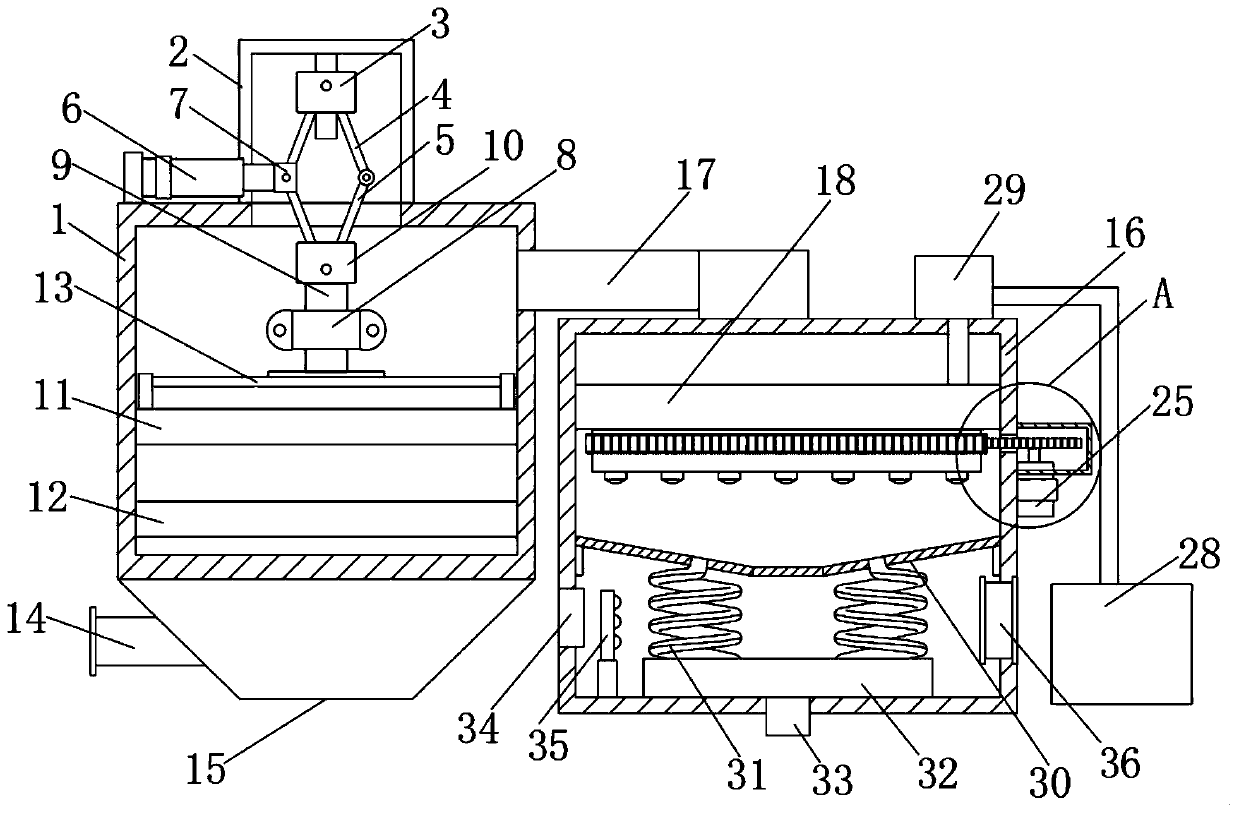

Recycled plastic melt filter

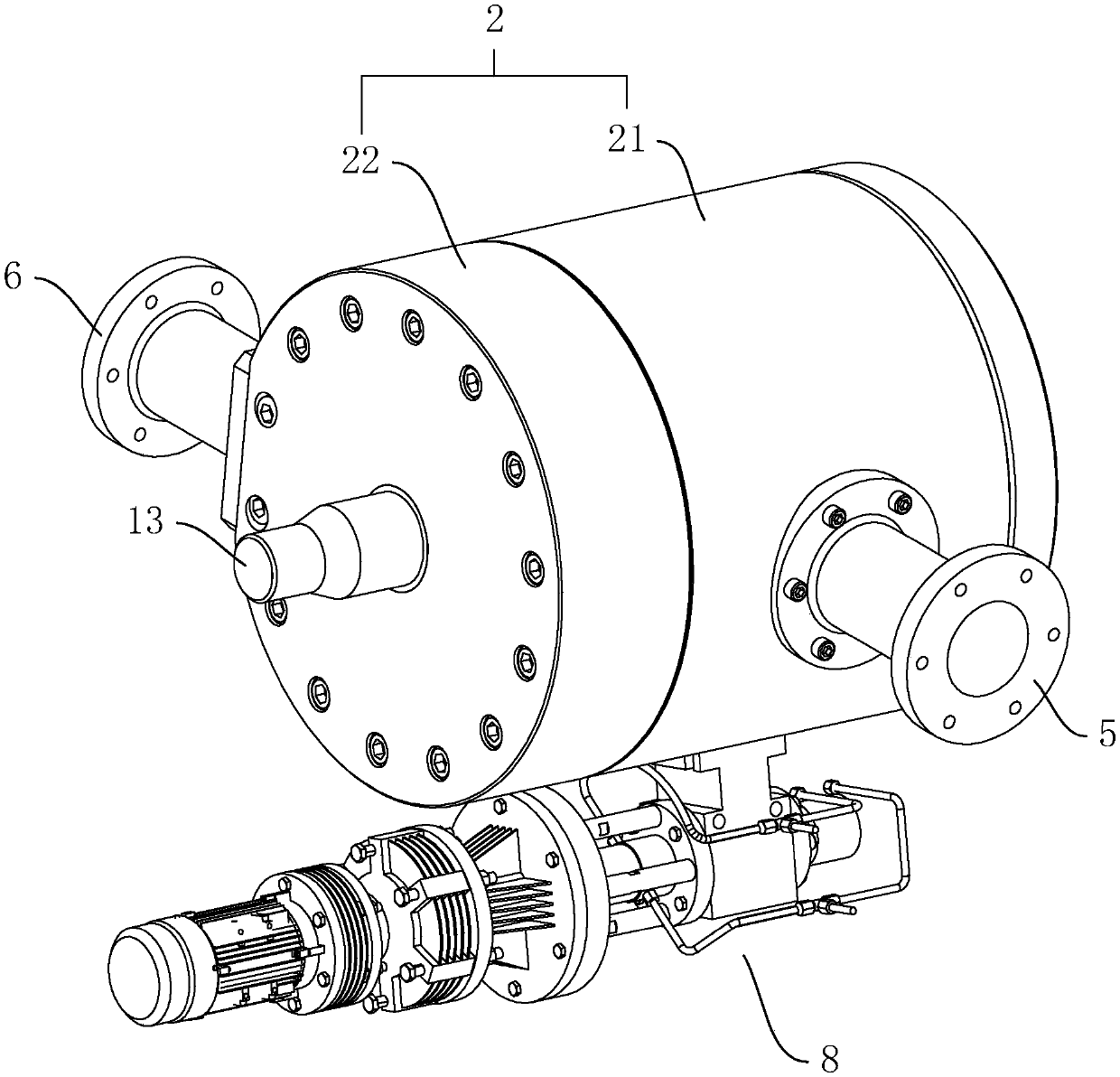

The invention discloses a recycled plastic melt filter, and relates to the technical field of filters. According to the technical scheme, the recycled plastic melt filter comprises a cylinder body provided with an inner cavity, a filter element is arranged inside the cylinder body, a plurality of filter holes are uniformly distributed in the filter element, a filter cavity is formed inside the filter element, and a feeding pipe and a discharge pipe are arranged on the side wall of the cylinder body; and an impurity removal port communicating with the inner cavity of the cylinder body is further formed in the cylinder body, and an impurity removing part is arranged at the impurity removal port; and the filter holes are uniformly distributed in the side wall of the filter element, so that alarge contact area is formed between melt plastic and the filter element, more melt plastic can be filtered in unit time, and it is illustrated that the recycled plastic melt filter has relatively high machining efficiency. The recycled plastic melt filter is mainly used for plastic extrusion production lines, and can directly carry out production or processing by using plastic reclaimed materialsor plastic wastes; and production or processing is not needed after plastic granulation is performed, so that pollution to the environment and unnecessary energy consumption are reduced.

Owner:ZHEJIANG LEENY TECH

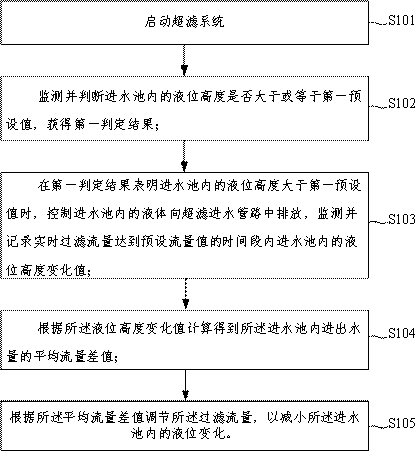

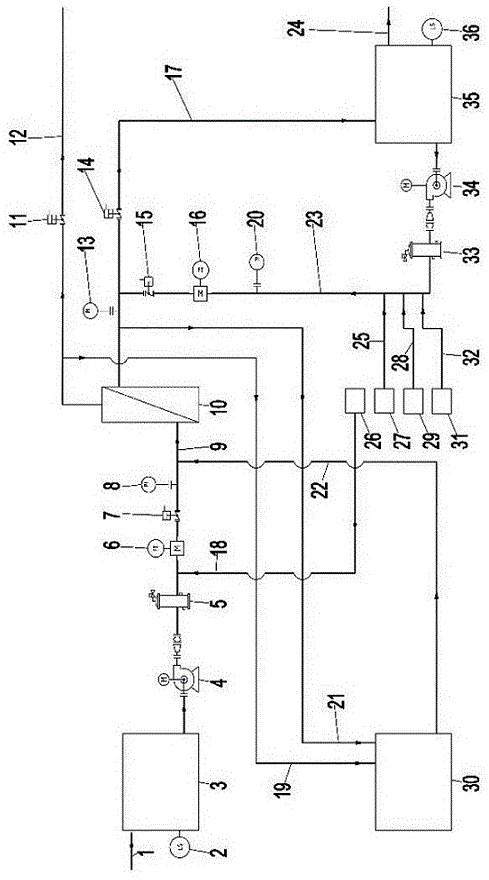

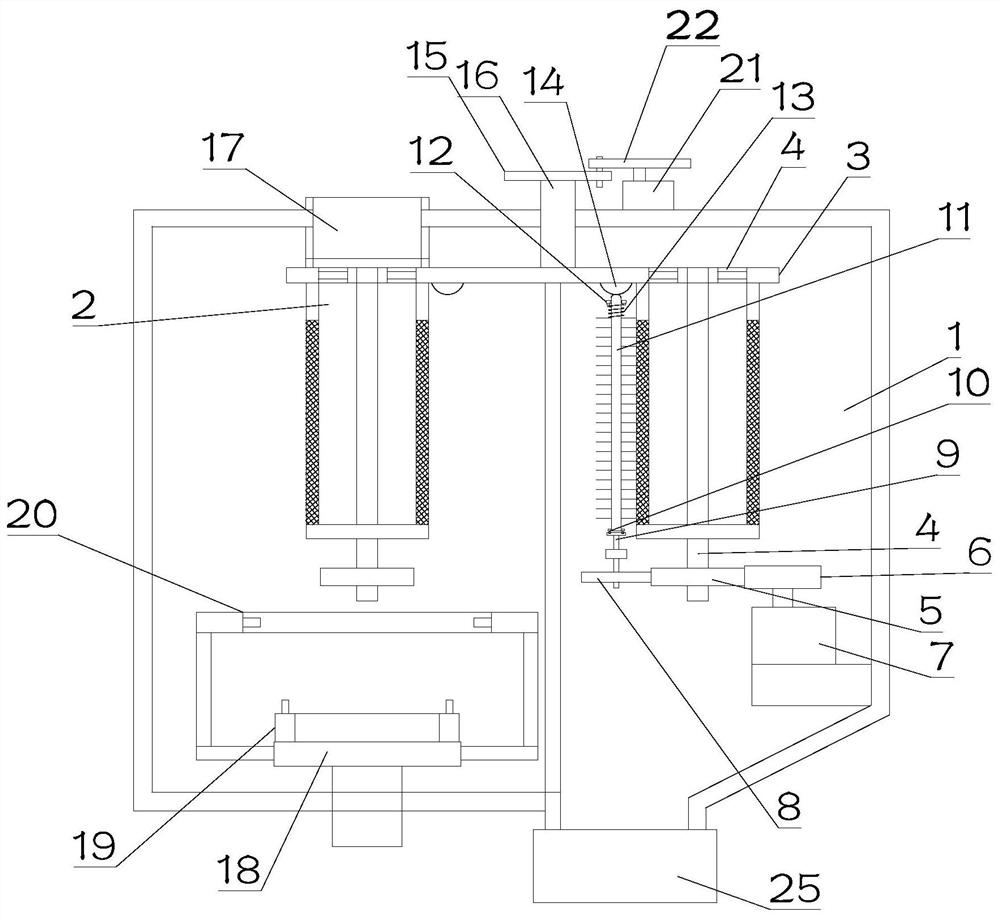

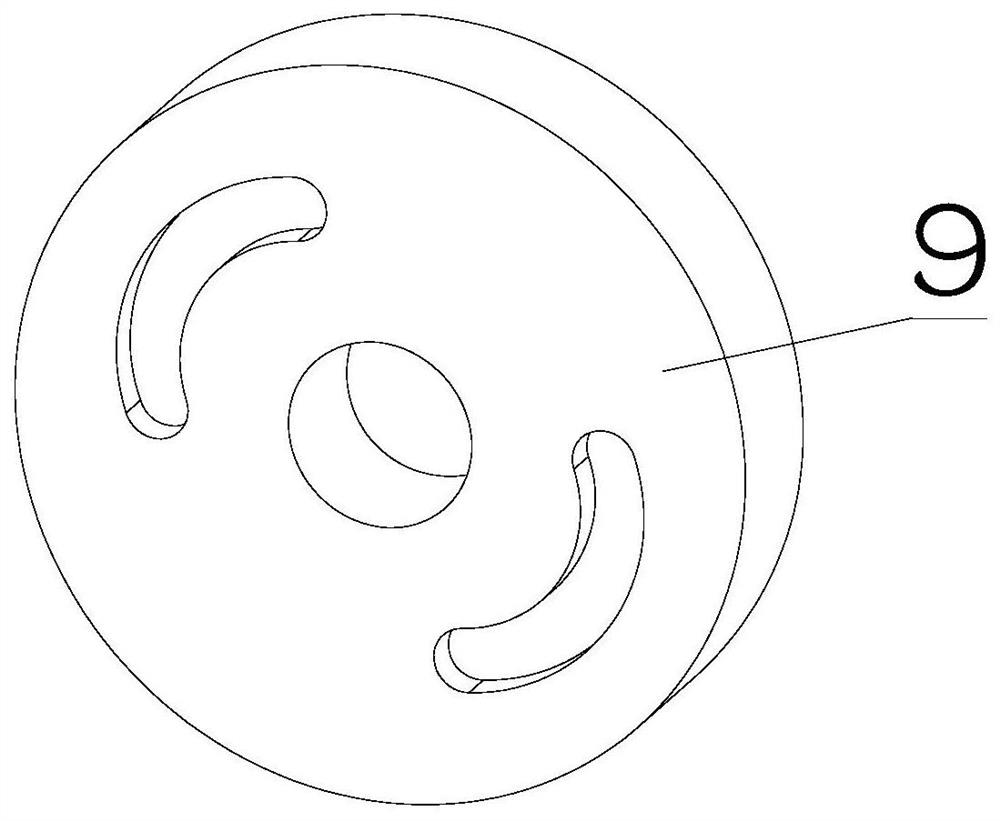

Energy-saving ultrafiltration system control method and ultrafiltration system

ActiveCN113041843ALiquid level stabilityLittle change in liquid levelWater treatment parameter controlSpecific water treatment objectivesUltrafiltrationStream flow

The invention relates to the technical field of sewage treatment, and in particular, relates to an energy-saving ultrafiltration system control method and an ultrafiltration system. The control method comprises the steps: starting the ultrafiltration system; monitoring and judging the liquid level height in a water inlet pool, when the liquid level height in the water inlet pool is larger than a first preset value, discharging liquid in the water inlet pool into an ultrafiltration water inlet pipeline, and monitoring and recording the liquid level height change value in the water inlet pool; calculating to obtain an average flow difference value; and adjusting the filtering flow, and reducing the liquid level change in the water inlet pool. According to the method provided by the invention, the time required for the filtering flow to reach the preset value and the change value of the liquid level height in the water inlet pool are monitored, so that the average flow difference value in the water inlet pool is obtained, and the difference value between the water inlet flow and the water outlet flow of the water inlet pool is reduced by adjusting the filtering flow, so that the liquid level change of the water inlet pool is reduced; the liquid level of the water inlet pool is relatively stable, continuous filtration of a filter membrane group is ensured, water consumption during shutdown flushing is reduced, water production cost is reduced, and energy conservation and consumption reduction of the system are realized.

Owner:GREENTECH ENVIRONMENTAL CO LTD

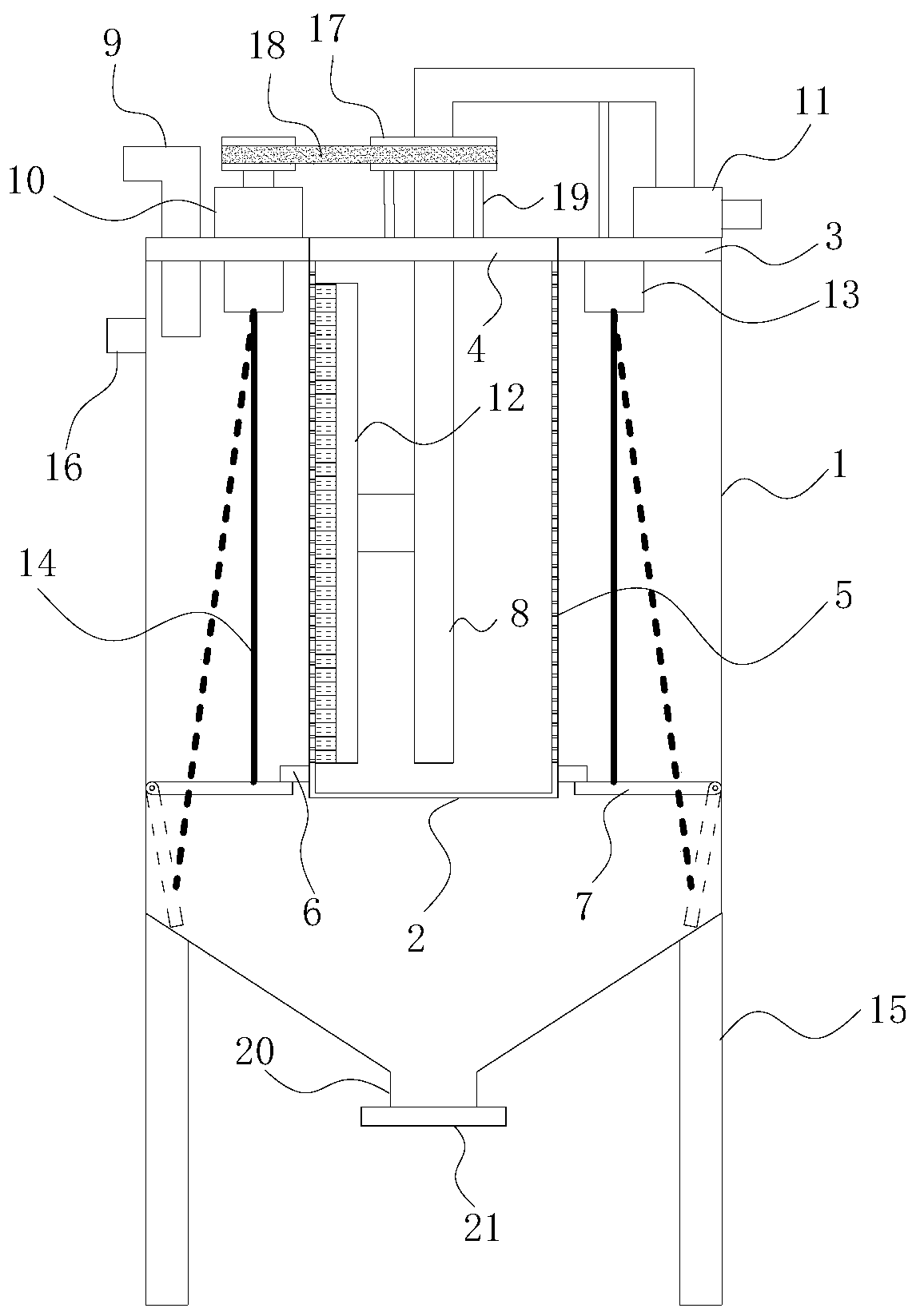

Dust removal device for building construction

InactiveCN112439278AIncrease exposureAvoid vertical collisionDispersed particle filtrationTransportation and packagingArchitectural engineeringDust control

The invention is suitable for the technical field of building construction equipment, and provides a dust removal device for building construction. The device includes a device main body, and the interior of the device main body is divided into a dust removal cavity and a cleaning cavity by a partition plate; a rotating disc is arranged in the device main body in an intermittent rotating mode, a plurality of filter screen cylinders are arranged at the bottom of the rotating disc in an array mode, the outer sides of supporting rotating shafts are fixedly sleeved with the lower ends of the multiple filter screen cylinders, and the upper ends of through holes are rotationally installed on the rotating disc, wherein the rotating disc is provided with multiple through holes in an array mode, and the multiples through holes are formed in outlets at the upper parts of the plurality of filter screen cylinders in a one-to-one correspondence manner; an exhaust cylinder is further arranged in thedust removal cavity, and the lower portion of the exhaust cylinder is arranged on one through hole in the dust removal cavity; an air inlet piece is fixedly mounted in the dust removal cavity, and isarranged below one filter screen cylinder of which the upper end communicates with the exhaust cylinder; and a plurality of first spray heads with upward openings are arranged on the air inlet piecein a circumferential array mode.

Owner:张治发

Self-cleaning tank type filtering separator

ActiveCN107080994ACompact structureSpeed up filteringStationary filtering element filtersWaste managementSelf adaptation

The invention discloses a self-cleaning tank type filtering separator which comprises a tank, a filtering assembly and a self-cleaning assembly. The filtering assembly comprises a filter pipe, a filter bag and the like. A filter hole is formed in the filter pipe, the upper end of the filter pipe is communicated with the interior of a water tank through a spherical pipe joint, and the filter pipe is sleeved with the filter bag which is fixed in a clamped mode. A water box and the tank are fixed. The self-cleaning assembly comprises a tank cover, a scraper blade, a scraping ring, a lead screw and the like; the tank cover is provided with a bearing pedestal and fixedly connected with the water box; the scraping ring is clamped into the scraper blade and provided with a movable clearance; the scraping ring penetrates through the filter bag and the filter pipe; a lead screw nut and the scraper blade are fixed; one end of the lead screw and the lead screw nut form a screw pair, and the other end of the lead screw is provided with a movable sealing ring, a bearing and a chain wheel and the like and assembled with the tank cover; under the drive the forward and backward rotation of the motor, the chain wheel and the chain, the lead screw automatically rotates synchronously, the scraper blade is driven by the lead screw nut to horizontally move up and down, self-adaptation adjustment of the scraping ring on the scraper blade is achieved, and the filter bag is scraped and cleaned. The self-cleaning tank type filtering separator has the advantages that the structure is novel and reasonable, the sealing performance is good, the filtering capability is high, various self-cleaning modes are adopted, and long-term automatic operation can be achieved easily.

Owner:HUBEI JUNJI WATER TREATMENT

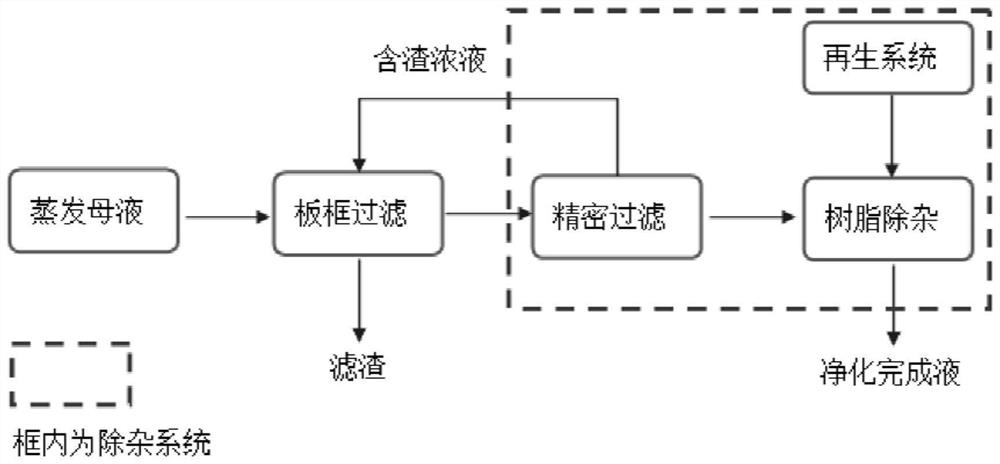

Impurity removal process for lithium sulfate purified liquid

InactiveCN113072081AGuarantee product qualityImprove product qualityLithium carbonates/bicarbonatesLithium sulfates/sulfitesCALCIUM CARBONATE/MAGNESIUM CARBONATELithium sulphate

The invention discloses an impurity removal process for a lithium sulfate purified liquid, belongs to the technical field of lithium sulfate preparation, and aims to provide an impurity removal process for a lithium sulfate purified liquid to solve the problem that the existing lithium sulfate purified liquid contains small-particle impurities and Ca<2+> impurities of insoluble substances such as calcium carbonate and magnesium carbonate and slightly soluble substances such as calcium sulfate and the quality of subsequent lithium carbonate products is poor. The method comprises the following steps of: (1) filtering by adopting a precision filter, and filtering and intercepting insoluble substances such as calcium carbonate and magnesium carbonate and slightly soluble substances such as calcium sulfate in the lithium sulfate purified liquid; and (2) selectively adsorbing soluble Ca<2+> impurities in the lithium sulfate solution through an ion exchange resin column to finish deep purification of the lithium sulfate purified solution. The method is suitable for impurity removal of the lithium sulfate purification completion liquid.

Owner:四川恩特普环保科技有限公司

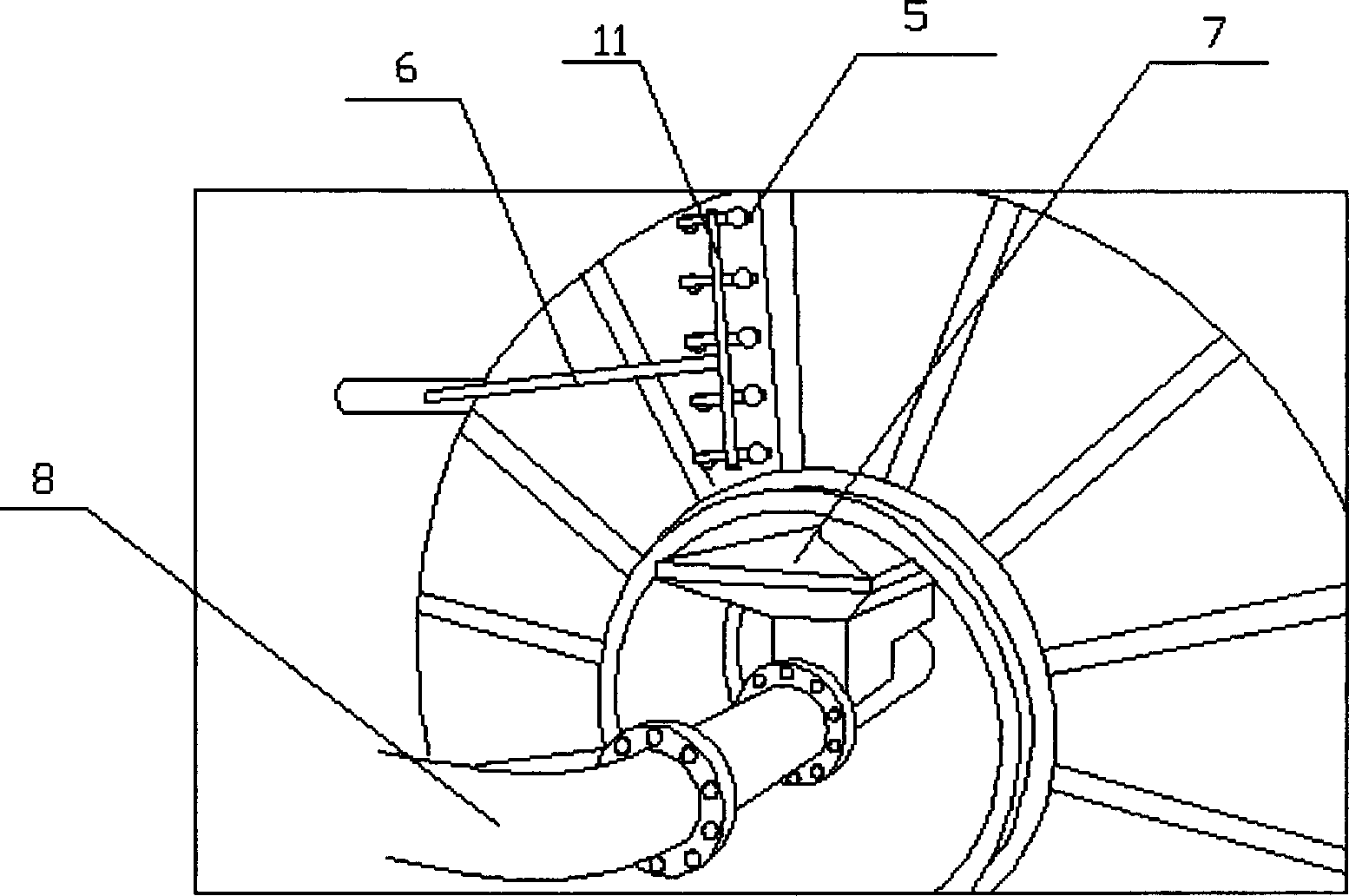

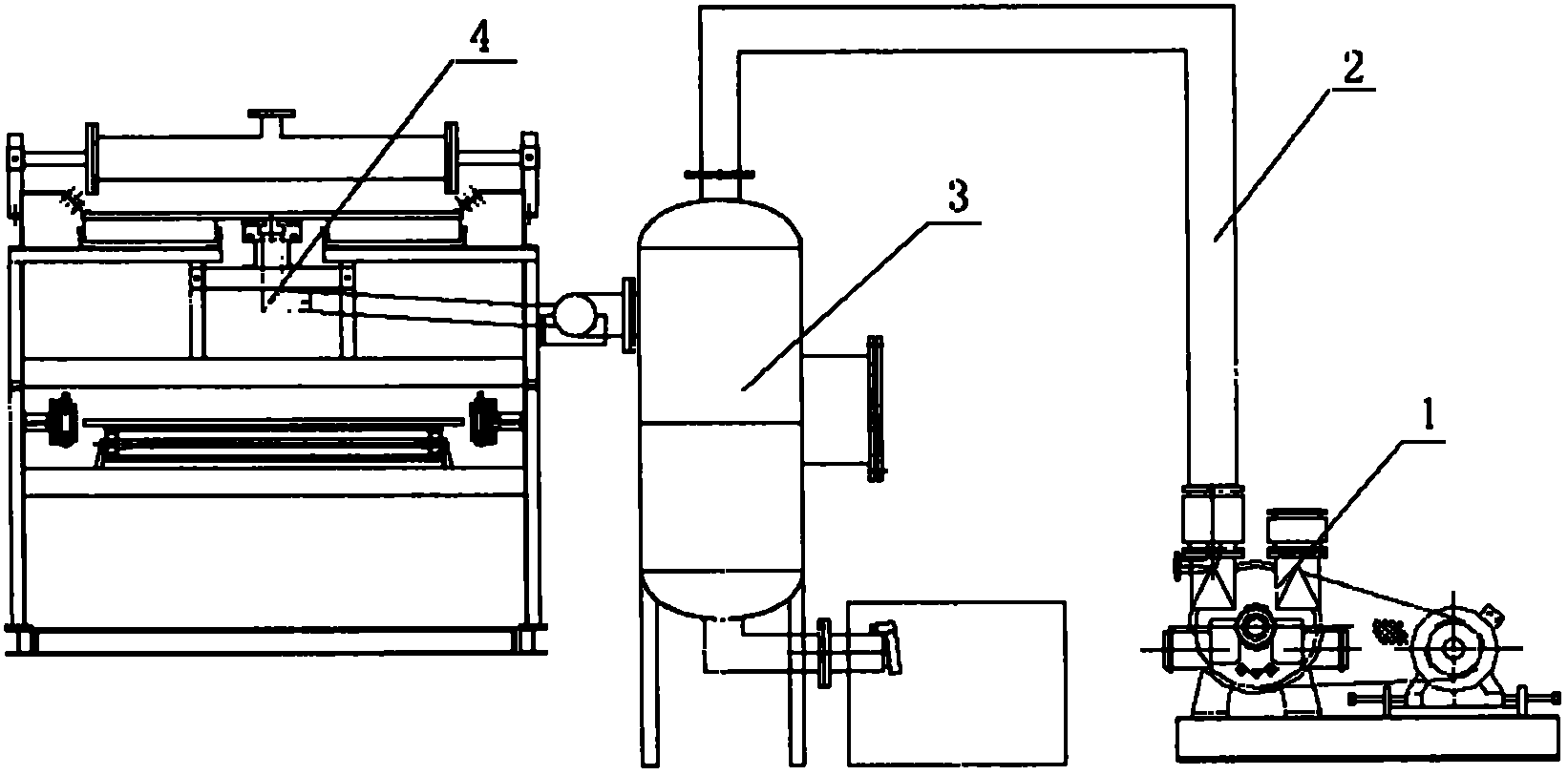

Solid-liquid separating technology

InactiveCN103752069ASimple device structureImprove the efficiency of solid-liquid separationFiltration separationPhosphoric acidEngineering

The invention discloses a solid-liquid separating technology. The solid-liquid separating apparatus comprises a vacuum pump (1), a liquid collecting pot (3) and a filter (4). The vacuum pump, the liquid collecting pot and the filter are connected by a vacuum tube (2) in series. The filtering equipment solid-liquid separating apparatus provided by the invention can generate extra negative pressure internally with the effect of vacuum pump, and impurity-containing solution can be absorbed into the liquid collecting pot for filtering materials; material moisture can be dried as possible, which ensures soluble impurities between particles to be completely washed, and impurity element content in ferric phosphate to be reduced to the lowest, thereby the material can meet the RoHs requirement of impurity element content in the lithium battery industry; the apparatus has the advantages of simple structure, continuous filtering and high solid-liquid separation efficiency.

Owner:魏宇

Traditional Chinese medicine filtering device

InactiveCN111617547AContinuous filtrationAvoid cloggingSeparation devicesFiltration circuitsEngineeringMechanical engineering

The invention relates to a traditional Chinese medicine filtering device. The technical scheme for solving the problems is as follows: the device comprises a shell with a cavity, a horizontally-arranged filter cartridge is arranged in the cavity, the filter cartridge is rotationally connected with the shell through the axis of the filter cartridge, a liquid inlet hole communicated with the inner side of the filter cartridge, a liquid outlet hole communicated with the cavity, a slag discharging hole communicated with the inner side of the filter cartridge and a plug matched with and corresponding to the slag discharging hole are formed in the shell, and the plug detachably plugs the slag discharging hole; and a driving device in transmission connection with the filter cartridge is arrangedon the shell. Rolling filtration can be achieved, filter holes in the bottom area of the filter cartridge are kept unobstructed, and therefore the filter efficiency is improved, and long-time continuous filtration of the filter cartridge is guaranteed.

Owner:THE FIRST AFFILIATED HOSPITAL OF XINXIANG MEDICAL UNIV

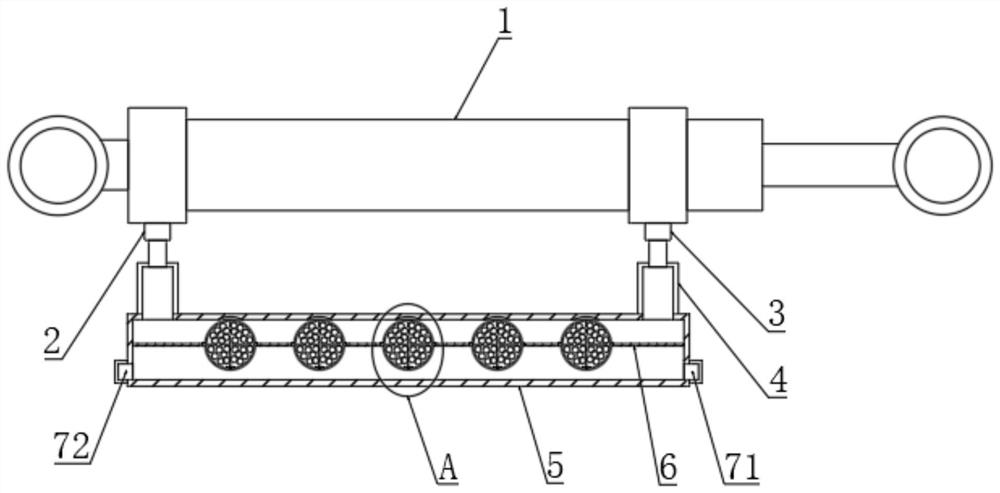

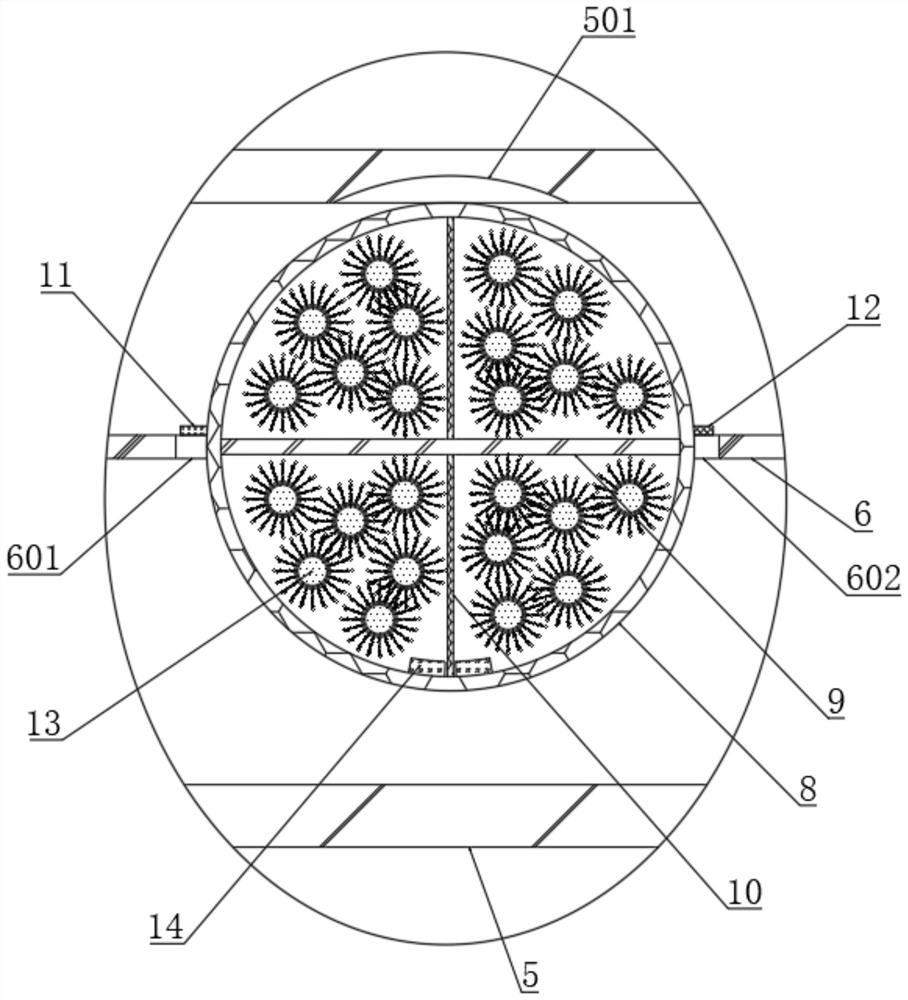

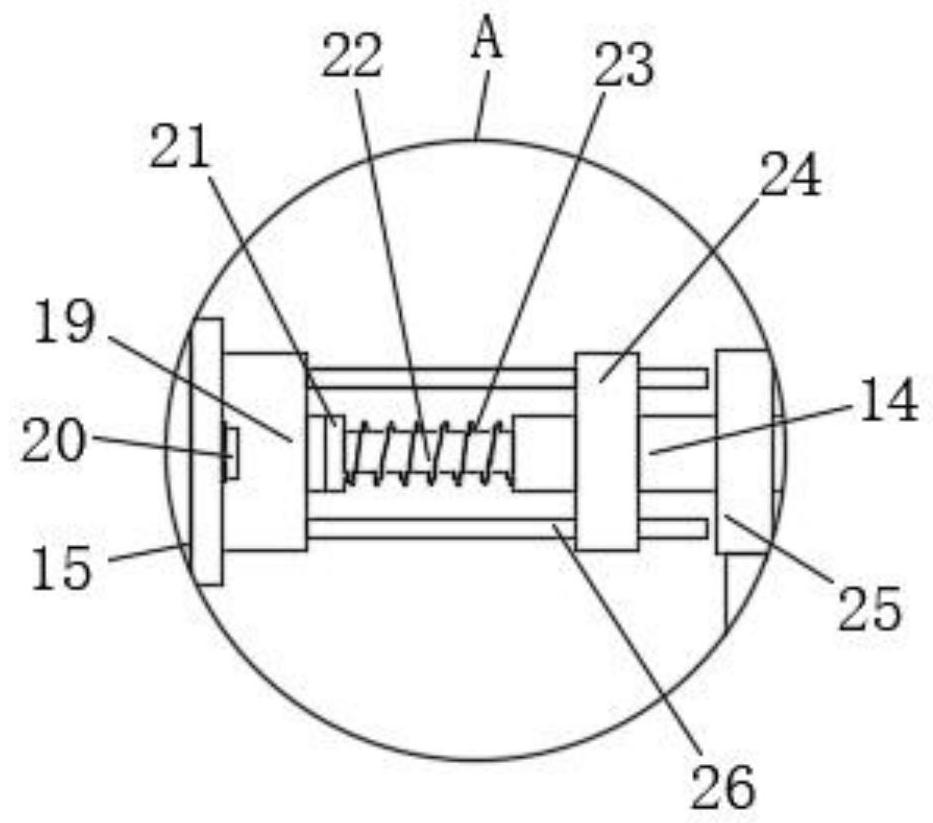

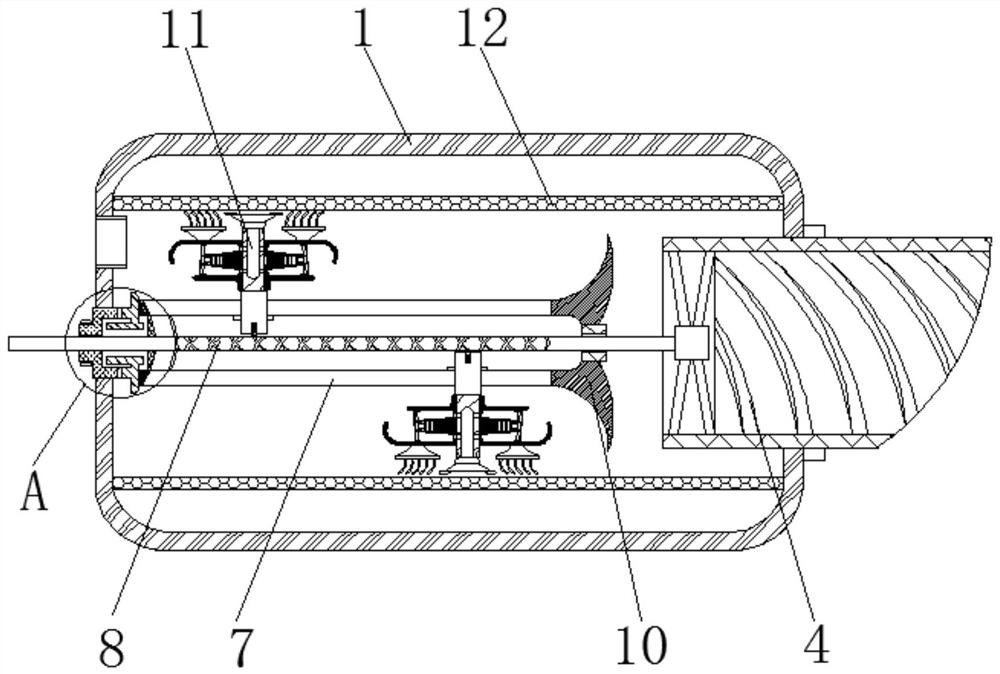

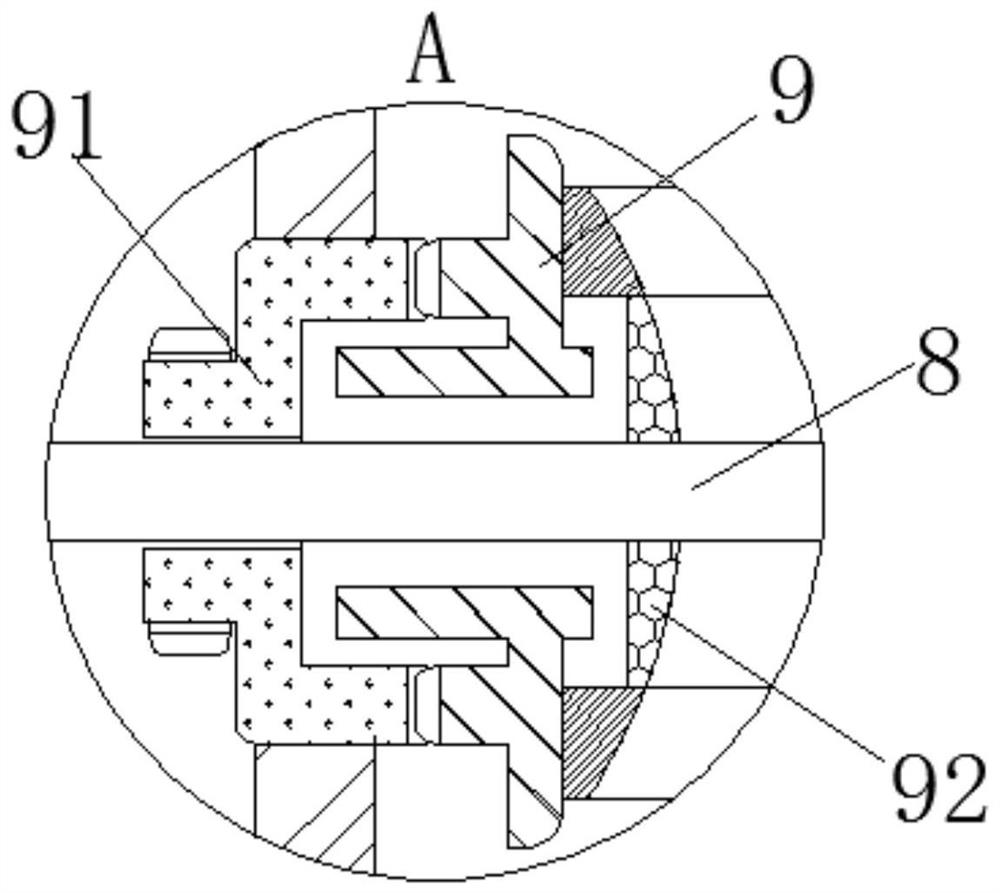

Oil filtering and cooling device for hydraulic oil cylinder

InactiveCN113417912AContinuous filtrationThe filtering effect is continuously effectiveFluid-pressure actuator componentsThermodynamicsHydraulic ram

The invention discloses an oil filtering and cooling device for a hydraulic oil cylinder, and belongs to the field of hydraulic oil cylinders. The oil filtering and cooling device comprises a cylinder body and a double-cavity pipe connected to the cylinder body, an oil injection pipe and an oil outlet pipe are fixedly connected to the cylinder body, connecting pipes are fixedly connected between the oil injection pipe and the double-cavity pipe and between the oil outlet pipe and the double-cavity pipe, and the connecting pipes are communicated with the interior of the double-cavity pipe. Filter balls capable of rotating reversely are arranged in the double-cavity pipe, half of the filter balls is located in hydraulic oil, and the other half of the filter balls is located in cooling clean oil, so that on one hand, the hydraulic oil in the flowing process is continuously filtered, and on the other hand, the filtered filter balls automatically rotate reversely by 180 degrees, and the filtered parts are transferred into the cooling clean oil for cooling and self-cleaning, and therefore, the continuous and effective filtering process of the hydraulic oil is realized through the filter balls, and meanwhile, the cooling effect on the hydraulic oil is also realized, and the service life of the cylinder body is greatly prolonged.

Owner:何德业

Water tank constant-pressure water supply device

InactiveCN112922080AContinuous filtrationEase of containmentHollow article cleaningWater supply tanksWater storage tankWater flow

The invention discloses a water tank constant-pressure water supply device, and particularly relates to the technical field of water supply devices. The water tank constant-pressure water supply device comprises a water storage tank, wherein the bottom end of the water storage tank is fixedly connected with a supporting seat; and a water outlet of the water storage tank communicates with a water supply mechanism through a flow guiding main tube. When the water tank constant-pressure water supply device needs to be cleaned, a hollow rotating shaft descends, a propeller blade is driven to rotate under the effect of water flow, a cleaning scraper and a bottom brush are driven to rotate to automatically clean water scale, when the hollow rotating shaft descends, a side cross rod is driven to descend synchronously, a pressing plate drives a primary filter plate to enter the flow guiding main tube, meanwhile, by a movable rod and a damping spring, the propeller blade is accommodated in a storage box conveniently, in the mode, power is provided by water flow to drive a cleaning structure to automatically clean the water scale, in a cleaning process, continuous filtering of the water flow is ensured, the circumstance that the water scale is accumulated in the equipment to affect the equipment is prevented, the cleaning structure has an integral accommodating function, and stability is provided for constant-pressure water supply of the equipment.

Owner:凌池英

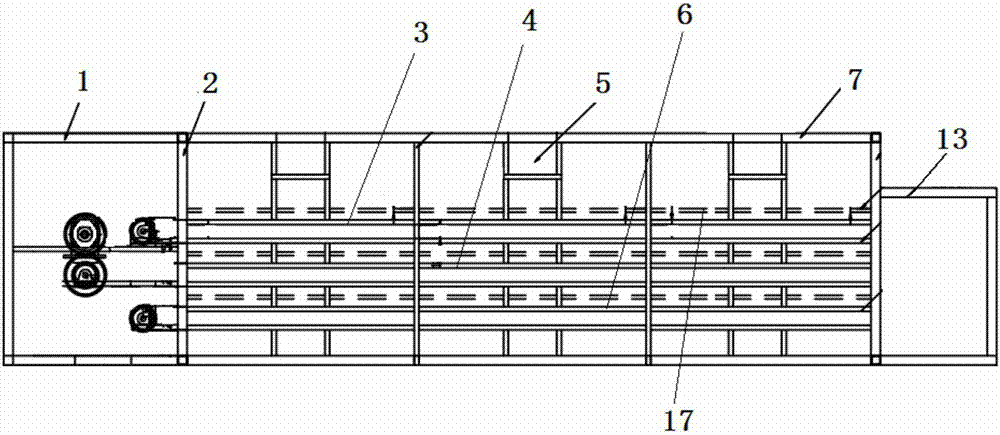

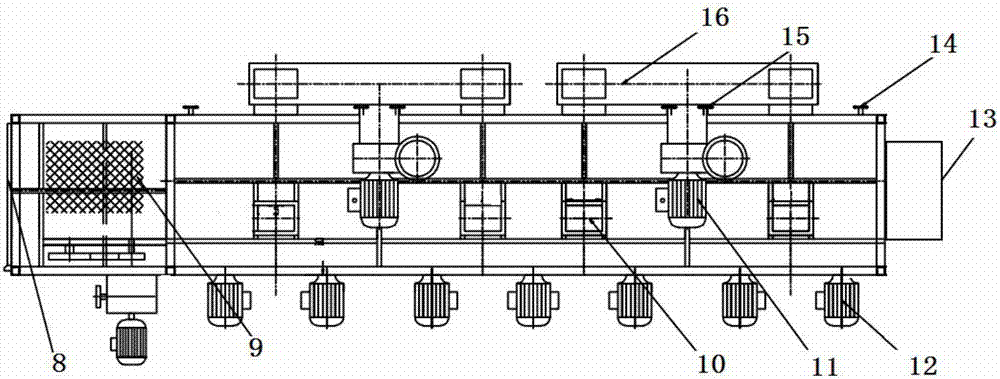

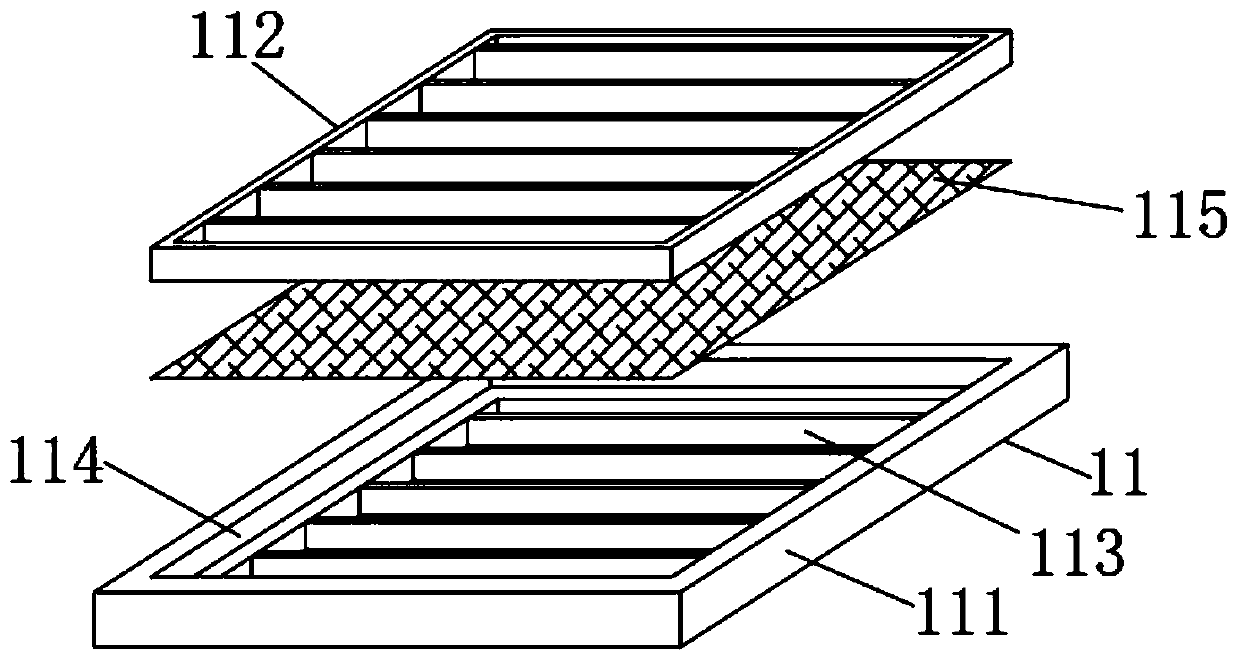

Multilayer drying machine with different filter screens

InactiveCN107356080AContinuous filtrationContinuous multi-layer drying of the filterDrying gas arrangementsDrying machines with progressive movementsProcess engineeringConveyor belt

The invention relates to a multilayer drying machine with different filter screens. A device main body crossbeam is inside provided with an upper layer conveyor belt, a middle layer conveyor belt and a lower layer conveyor belt, and the three layers of conveyor belts are connected through a conveyor belt drive unit; humidity elimination gas ports and compensation wind inlets are arranged among the three layers of conveyor belts; a hopper is arranged on a right fixed support end, and a humidity elimination blower fan and a circulating blower fan are arranged on the device main body crossbeam; a bent pipeline is arranged between a heat exchanger device and a heat exchanger outlet, and the bent pipeline is arranged among the three layers of conveyor belts; a humidity elimination trunk pipe is connected with the humidity elimination blower fan; and the upper layer conveyor belt, the middle layer conveyor belt and the lower layer conveyor belt are provided with filter screens with through holes in different sizes. The multilayer drying machine with different filter screens is advantaged in that according to characteristics of pie-shaped, bar-shaped and spherical catalyst process materials by means of a precipitation method, a band extrusion method and an immersion method, a multilayer high-strength stainless steel netted crawler belt is arranged, the gap of the crawler belt is reasonably controlled, and the aim of general and continuous drying and layered filtering of materials is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bag type filtering equipment and using method thereof

InactiveCN112023489AContinuous filtrationLarge amount of filtrationStationary filtering element filtersGear wheelElectric machinery

The invention discloses bag type filtering equipment and a using method thereof. The equipment comprises a support, a water inlet in the upper end of the support, a motor, a scraper, a fixing shaft onthe right side of the scraper, a plurality of springs on the scraper, a plurality of gears fixed to the support, fixing shaft rods distributed on the upper side and the lower side of a filter screen,a 200-mesh modular filter screen with the mesh number capable of being changed, a 400-mesh modular filter screen, a 600-mesh modular filter screen, chains embedded in the filter screens and having the same number as the gears, modular water baffles distributed on the two sides of the filter screens, filter screen guide grooves distributed in the upper sides and the lower sides of the filter screens, and a water outlet in the lower end of the support. Compared with the prior art, the bag type filtering equipment has the advantages of continuous filtration, large filtration capacity, low cost,simplicity in operation and zero emission.

Owner:邢献军

An ecological floating island for restoration and treatment of black and odorous water

ActiveCN110282745BPurify the surrounding environmentImprove flotationSpecific water treatment objectivesWater/sewage treatment apparatusSewageZoology

The invention discloses an ecological floating island for the restoration and treatment of black and odorous water bodies, which includes a floating seat, a mesh cylinder seat, a floating ball, a balance frame, a steel wire rope and fixed rivets, the bottom of the purification seat is welded with a mesh cylinder seat, and A floating seat is fixed on the outer wall of the clean seat at the junction of the clean seat and the net-shaped cylinder seat, and one end of the drive motor shaft is installed inside the raised top of the clean seat and extends to the bottom of the net-shaped cylinder seat and a turret is installed. A balance frame is installed at the bottom of the turret, a steel wire rope is connected to the center of the bottom of the balance frame, and a fixed rivet is fixed at one end of the steel wire rope. The present invention can effectively adjust the black and odorous water body through the rhizome of aquatic plants by installing the floating seat, the purification seat, the floating ball and the ecological planting tank, and can effectively collect the floating matter on the surface of the water body through the floating island to increase the area of the purified water area and solve the problem of Traditional sewage purification devices have problems such as single purification function, small purification area, long treatment time, slow purification rate, and high maintenance cost.

Owner:ANHUI LANDING ENVIRONMENTAL PROTECTION ENERGY TECH

Grid for sewage treatment

InactiveCN108821367AContinuous filtrationPrevent splashTreatment involving filtrationSewageEngineering

The invention discloses a grid for sewage treatment. The grid comprises a grid body, wherein a base plate is horizontally arranged at one side of the grid body; first fixed seats are respectively arranged at both sides of the base plate; a conveying belt is horizontally arranged at the top part of the base plate; support plates are respectively arranged at both sides of the conveying belt; a blocking plate is arranged at the top part of each support plate; a second fixed seat is arranged at one end of the conveying belt; a roller brush is arranged at the top end of the second fixed seat; a second motor is arranged at one side of the grid body, and a first motor is arranged at one end of the roller brush. The grid has the advantages that the revolving type grid is adopted, and is driven bythe second motor to cyclically run, so that the sewage entering a sewage treatment tank can be continuously filtered; the roller brush is tangential with the grid body, and the running direction of the grid body is opposite to the rotation direction of the roller brush, so that the purpose of clearing the stuck pollutants on a grid chain by the roller brush is realized.

Owner:HEFEI HEXING ECOLOGICAL CULTURING TECH CO LTD

Textile printing and dyeing wastewater recovery treatment system and method thereof

PendingCN113402069APromote precipitationImprove efficiencySpecific water treatment objectivesTreatment involving filtrationTextile printerWater flow

The invention discloses a textile printing and dyeing wastewater recovery treatment system and a method thereof. The textile printing and dyeing wastewater recovery treatment system comprises a first filtering mechanism, the first filtering mechanism comprises two supporting seats, a cleaning part and a driving part, the tops of the two supporting seats are fixedly connected with a bottom frame, and the bottom of the bottom frame communicates with a spiral mixing frame; and a plurality of supporting pieces are fixedly connected to the inner surface wall of the bottom frame in the circumferential direction at equal intervals. According to the invention, wastewater and a degradation reagent are continuously injected into a liquid storage frame, so that the wastewater can be effectively injected into a mixing frame through the liquid storage frame, and flowing water flow in the process can effectively impact a linkage impeller, so that the linkage impeller can effectively drive a second bevel gear to rotate through a first linkage shaft; and under the cooperation of two second bevel gears, a first linkage shaft can effectively drive a second linkage shaft to rotate, and then the second linkage shaft can effectively drive stirring blades to stir and mix wastewater and degradation reagents.

Owner:翁作容

High-efficiency automatic soil filtering device

PendingCN109569050AContinuous filtrationSpeed up filteringStationary filtering element filtersEngineeringFilter paper

The invention discloses a high-efficiency automatic soil filtering device which comprises a supporting plate, a first rotating frame, a second rotating frame, a first driving mechanism and a driving mechanism. The driving mechanism is used for driving the first rotating frame and the second rotating frame to rotate, an up-down through filter hole is formed in the supporting plate, a filter paper component with automatically replaceable filter paper is arranged at the filter hole, a plurality of annularly arranged stock solution containers are arranged on the first rotating frame, each stock solution container is provided with a downward solution outlet, the solution outlets in the stock solution containers sequentially pass the upper portion of the filter hole in the rotating process of the first rotating frame, a plurality of annularly arranged filtrate containers are arranged on the second rotating frame, a solution inlet is formed in the top of each filtrate container, and the solution inlets of the filtrate containers sequentially pass the lower portion of the filter hole in the rotating process of the second rotating frame. Different samples are continuously filtered, and soilfiltering speed is effectively increased.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A slag water separation and recovery device

The invention relates to a slag-water separation recovery device. The device comprises a tube body and filtering tube, the outer side wall of the lower portion of the filtering tube is rotatably connected with an annular sealing plate, the side wall of the filtering tube is provided with a filtering hole, the filtering hole is formed in the upper portion of the sealing plate, a tube cover is arranged on the upper portion of the tube body, the tube cover comprises an outer cover and an inner cover, the inner cover is rotatably connected with the outer cover, the filtering tube is fixedly connected with the inner cover, the outer cover is fixedly connected with a motor, the inner cover is driven to rotate by the motor, the outer cover is provided with a water inlet pipe, the middle of the inner cover is rotatably connected with a water outlet pipe, the lower end of the water outlet pipe extends to the bottom of the filtering tube through a through hole, the upper end of the water outletpipe is connected with a water pump, the water outlet pipe is fixedly connected with a brush, a separation plate is arranged between the filtering tube and the tube body, one end of the separation plate is hinged to the side wall of the tube body, a chain is connected with the separation plate, and the chain is connected with an electric hoist, the slag in a filtering hole is thrown out and brushed out by the brush by the rotation of the filter tube, and the filtering hole is prevented from being blocked by the slag.

Owner:贺州市骏鑫矿产品有限责任公司

Filtering tank for quickly treating domestic sewage

InactiveCN112516653AContinuous filtrationAvoid corrosionTreatment involving filtrationGrey water treatmentMicroorganismSewage

The invention relates to the technical field of energy conservation and environmental protection, and discloses a filtering tank for quickly treating domestic sewage. The filtering tank comprises a tank body, wherein a water inlet pipe is arranged at the upper part of the left end of the tank body, an observation port is arranged at the top of the tank body, a blow-off pipe is arranged at the right side of the tank body, a base is arranged below the tank body, a water outlet pipe is arranged at the bottom of the tank body, a driving pipe is arranged in the center of the tank body, a lead screwis arranged in the driving pipe, the left end of the driving pipe is fixedly connected with a sealing terminal, a gear at the left end of the sealing terminal is connected with an outer coupling shaft in a meshed mode, a sealing lining is arranged in the sealing terminal, and fan blades are arranged at the right end of the driving pipe. According to the filtering tank for quickly treating domestic sewage, the impeller is driven to rotate through force unloading of a cleaning spring, negative pressure is generated in a hollow frame, bacterial colonies on the filter screen are sucked into the middle of the tank body through a suction nozzle, cleaning of microorganisms attached to the filter screen is achieved, the filtering quality is guaranteed, corrosion of the filter screen is prevented,and the service life is shortened.

Owner:潘林火

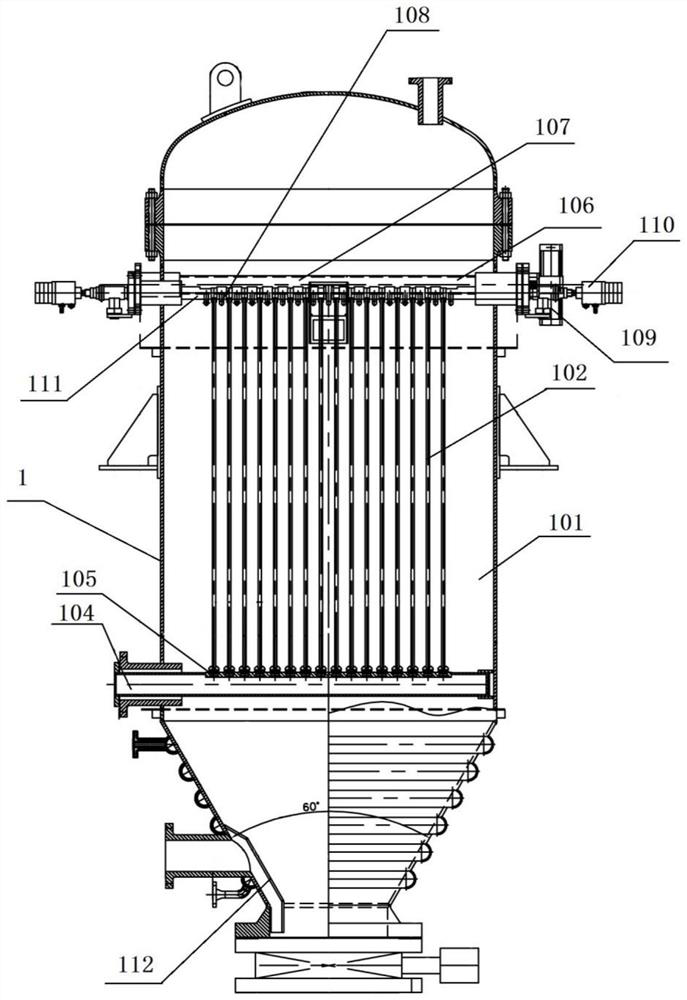

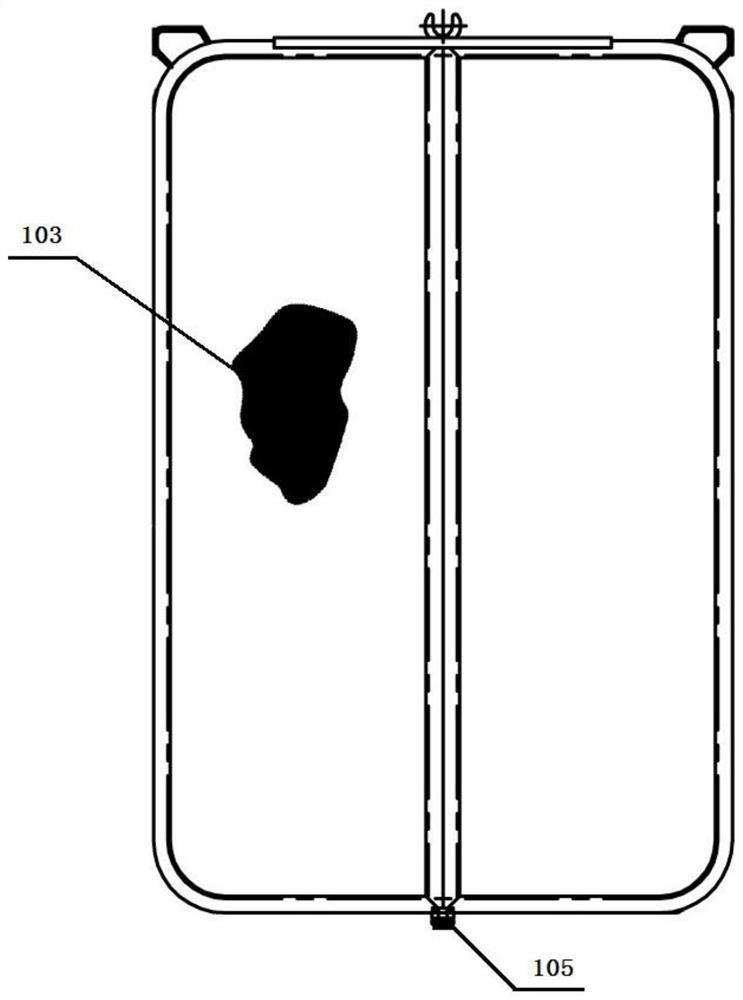

Pre-coating filtering system capable of continuously operating for long period

PendingCN112090168ACompact structureSmall footprintStationary filtering element filtersContinuous operationProcess engineering

The invention discloses a pre-coating filtering system capable of continuously operating for a long period, and relates to the technical field of filtering devices. The system comprises a pre-coatingunit, an auxiliary unit and a filtering unit, the pre-coating unit comprises a pre-coating feeding device, a pre-coating tank and a pre-coating circulating pump, the auxiliary unit comprises an auxiliary feeding device, an auxiliary tank and an auxiliary pump, and the filtering unit comprises a blade type filter, a deslagging trolley and a filtrate tank; the pre-coating filtering system is furtherprovided with an oil slurry raw material valve, the blade type filter is provided with a filter shell and a plurality of sets of filter blades, and the filter blades are installed in the filter shell. The pre-coating filtering system is good in catalytic cracking slurry oil filtering effect, full automation and automatic filter switching can be achieved, solid impurities are prevented from blocking a filtering medium in a pre-coating mode before filtering, the service life of the filtering medium is greatly prolonged, and long-period continuous operation can be achieved.

Owner:北京中科永亿科技有限公司

Anti-blockage sewage filter

The invention provides an anti-blockage sewage filter. The anti-blockage sewage filter comprises a shell, a water inlet is formed in the upper part of the shell, a first filter chamber is arranged inthe shell, a second filter chamber is arranged in the first filter chamber, the second filter chamber is connected to a water outlet, and a sedimentation tank is arranged on the bottom of the shell; the first filter chamber comprises a herringbone flow guide plate located on the centering of top and at the position of the water inlet, first blind plates located on both sides and connected to the flow guide plate, and a first screen plate located on the bottom; the second filter chamber comprises a second screen plate located on the upper part and a second blind plate located on the bottom; a water outlet pipe is connected to the water outlet, and a suction pump is connected to the water outlet pipe. According to the filter, the blockage of a filter screen caused by large-size particles isprevented, the process of filtration is continuous, and the operation of equipment is stable and reliable.

Owner:南京圆点环境清洁技术有限公司

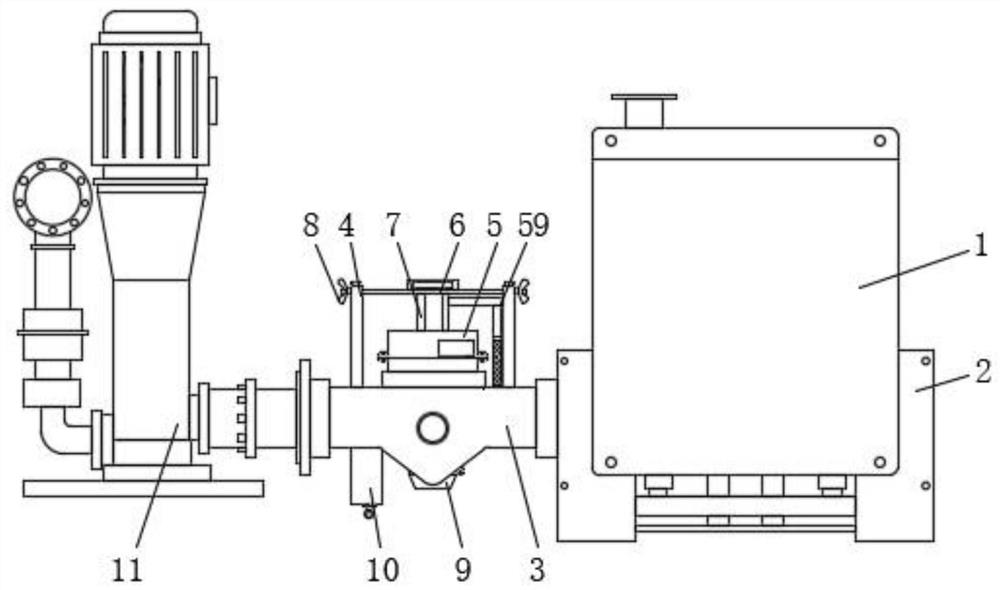

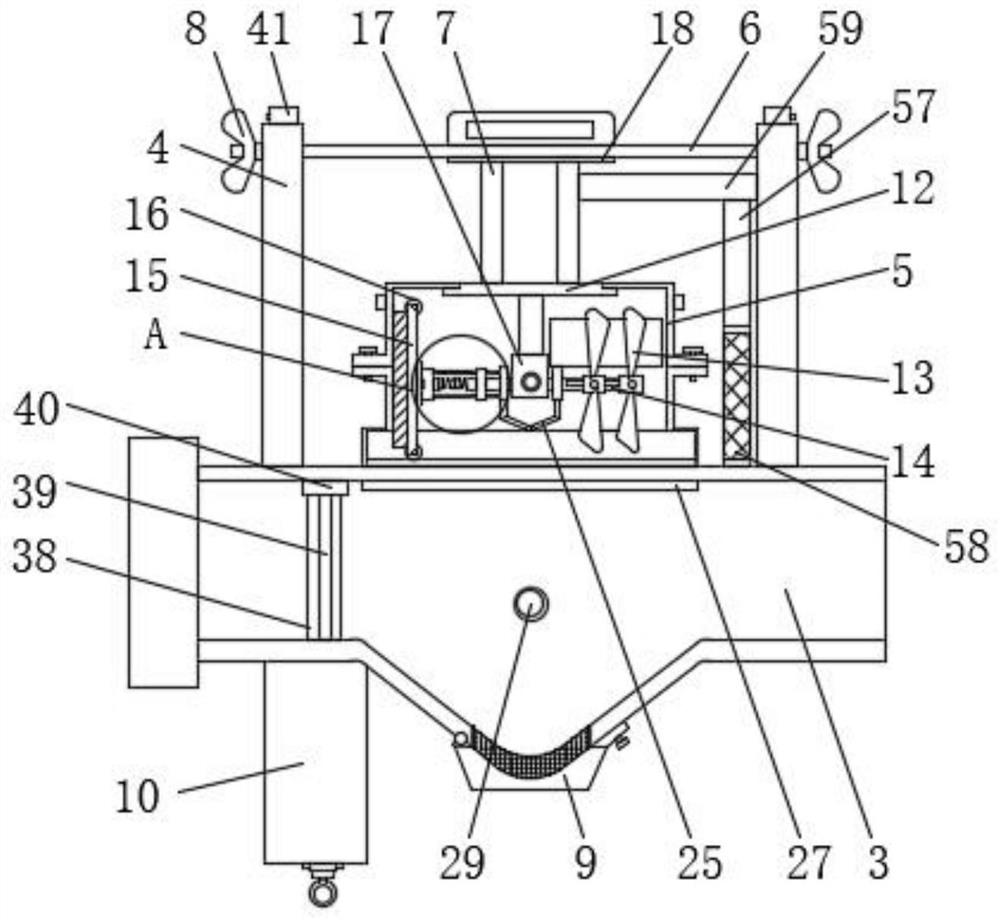

Quenching collection and treatment system based on smelting flue gas

InactiveCN111389210AClean up in timeEasy to filterGas treatmentDispersed particle filtrationHydraulic cylinderThermodynamics

The invention relates to the technical field of smelting flue gas treatment, and further discloses a quenching collection and treatment system based on smelting flue gas. The system comprises a filterbox, a treatment box and an alkali liquor storage pool, the top end of the filter box is fixedly connected with a connecting box; a first mounting block is arranged in the connecting box; two first rotating rods are rotationally connected into the first mounting block through a rotating shaft; one end of each of the two first rotating rods is rotatably connected with a second rotating rod, a hydraulic cylinder is fixedly installed on the side wall of the connecting box, the output end of the hydraulic cylinder is fixedly connected with a fixing piece, and a rotating shaft between the first rotating rods and the second rotating rods is fixedly connected into the fixing piece. According to the quenching collection and treatment system based on the smelting flue gas, dust in the flue gas canbe continuously filtered, the filtering strength of a filtering net can be guaranteed while the filtering efficiency is guaranteed, atomization is more uniform, the concentration is enough to absorbsulfur dioxide, and the flue gas can be well cooled.

Owner:路蓉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com