Textile printing and dyeing wastewater recovery treatment system and method thereof

A waste water recovery and treatment system technology, which is applied in textile industry waste water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low use efficiency and poor use effect, and achieve the effect of improving the actual use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

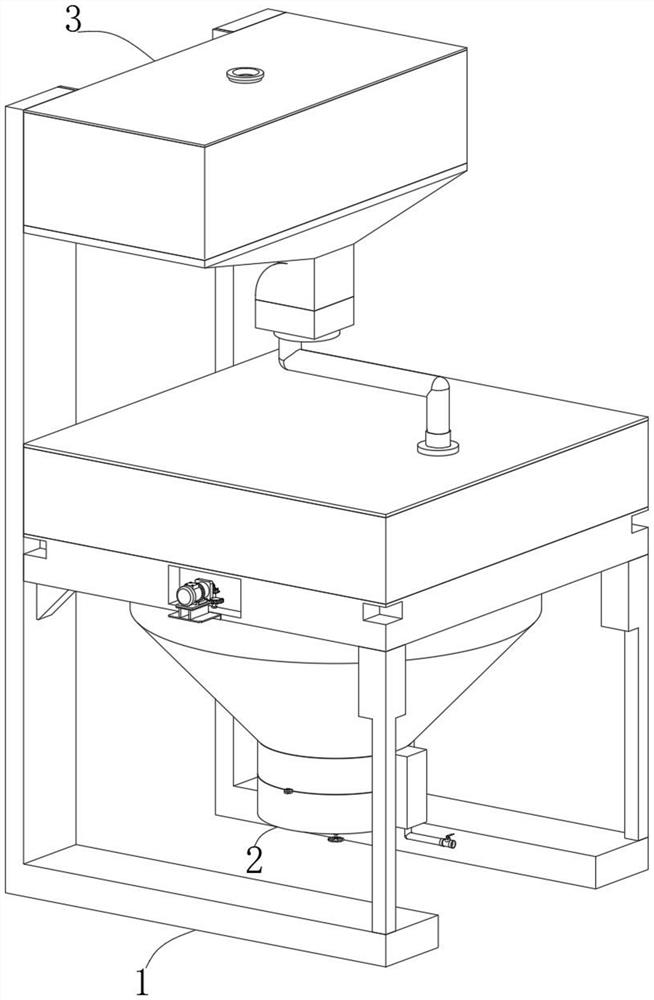

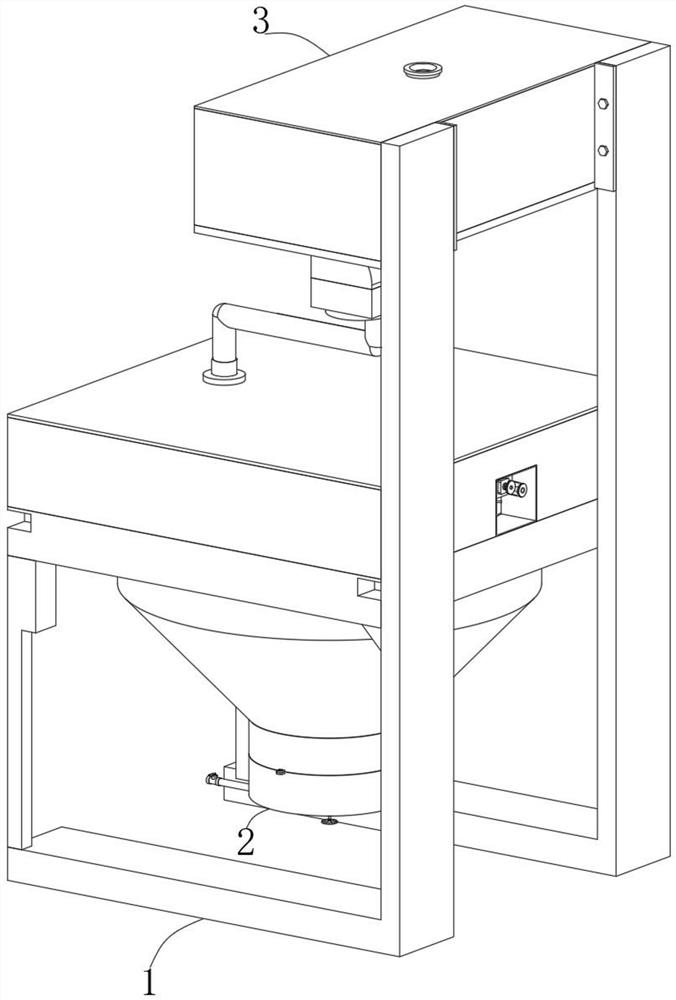

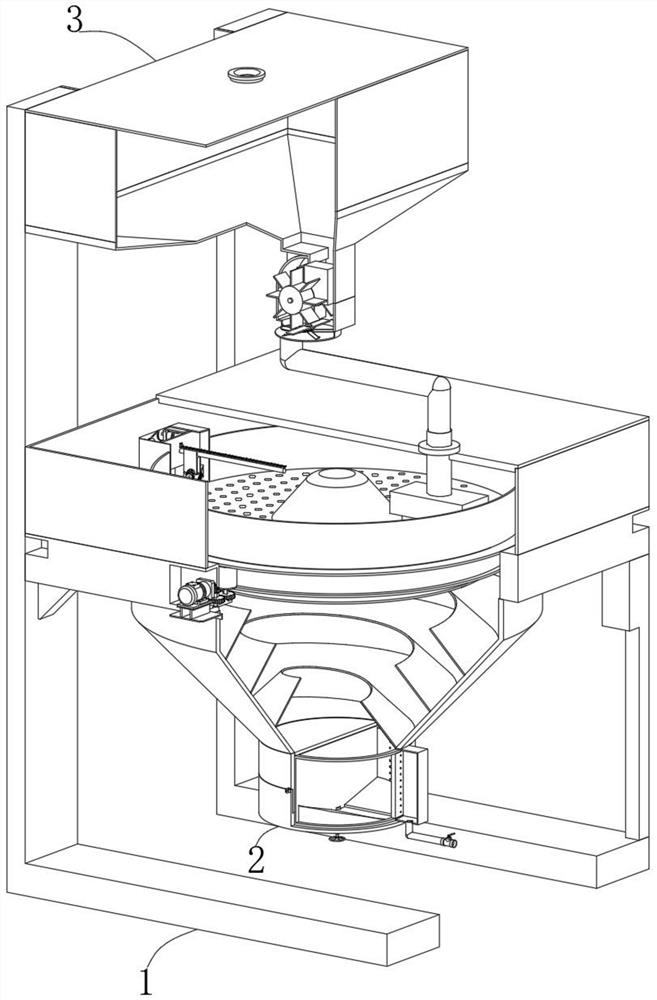

[0037] Embodiment one, with reference to Figure 1-12 : A textile printing and dyeing wastewater recovery treatment system, comprising: a first filter mechanism 1, the first filter mechanism 1 includes two support bases 101, cleaning components and driving components, the establishment of the support base 101 provides an installation basis for other functional components of the equipment The bottom frame 102 is fixedly connected to the top of the two support bases 101. The establishment of the bottom frame 102 facilitates the installation and setting of other functional parts of the equipment. The bottom of the bottom frame 102 is connected with a spiral mixing frame 109. The reagents for degradation can fully react, and the inner surface wall of the bottom frame 102 is equidistantly fixedly connected with a plurality of supporting plates along the circumferential direction. The supporting plates are set up to facilitate the installation and setting of the first supporting shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com