Treatment and recycling technology of white water in production of paper-making reconstituted tobacco

A technology of reconstituted tobacco leaves and papermaking, which is applied in the field of white water treatment and reuse technology, can solve the problems that the recovery rate of tobacco fibers, outer fibers and fillers cannot be achieved, it is not suitable for the annual production of reconstituted tobacco leaf production lines, and the operating costs are high, so as to save raw materials, Significant economic benefits and the effect of reducing the pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

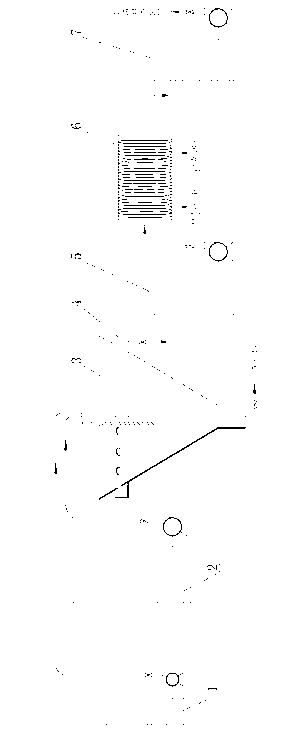

[0014] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

[0015] Such as figure 1 Shown is a flow chart of the white water treatment and reuse process in the production of reconstituted tobacco leaves by the papermaking method of the present invention, including primary flocculation and sedimentation treatment, multi-disc filter finishing treatment, including a flocculant storage pool 1, a white water pool 2, and a conical Sedimentation tank 3, overflow tank 4, clean water tank 5, multi-disc filter 6, ultra-clear water tank 7, pumps, valves, etc., and the white water generated by the wet part during the substrate forming process on the reconstituted tobacco production line is stored in the white water tank 2 The flocculant is stored in the flocculant storage tank 1, the upper center of the conical sedimentation tank is the white water inlet, the flocculant inlet, and the lower slag outlet, and the upper peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com