Dust removal device for building construction

A dust removal device and construction technology, applied in the direction of transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as blockage, limitation of the contact surface between air and filter, and affect filtration efficiency, so as to improve filtration efficiency, High filtering effect, the effect of increasing the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

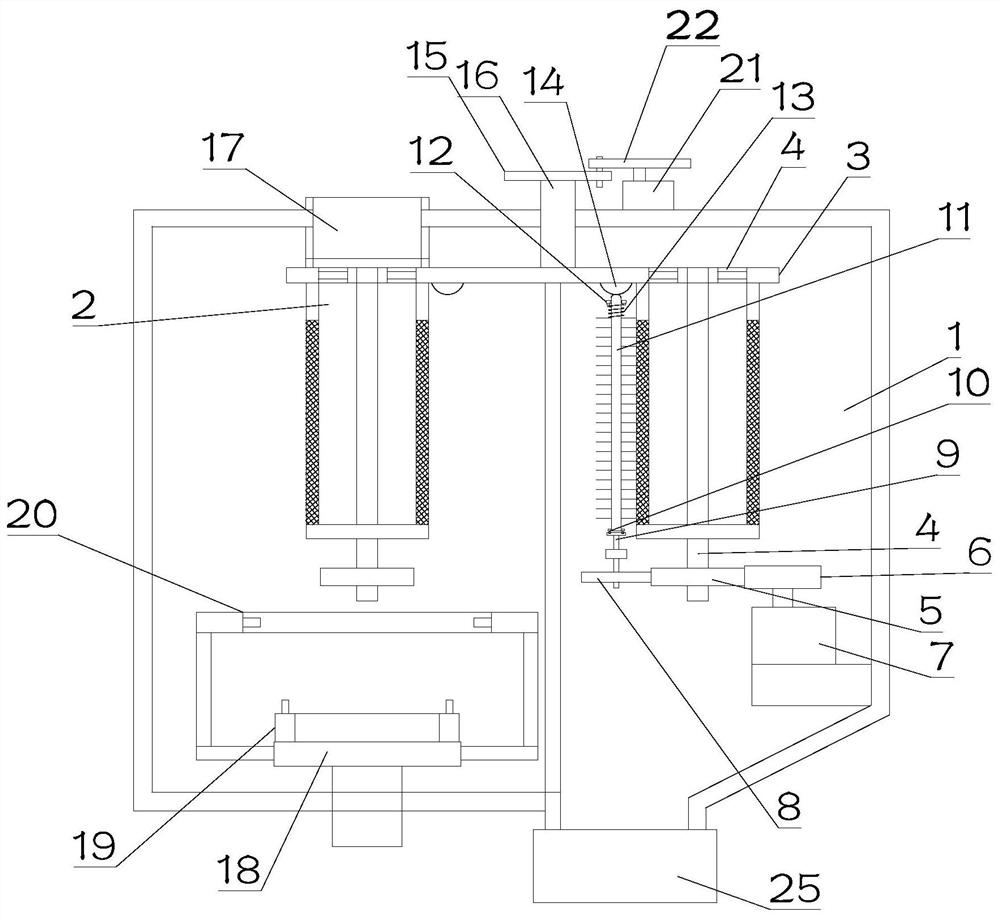

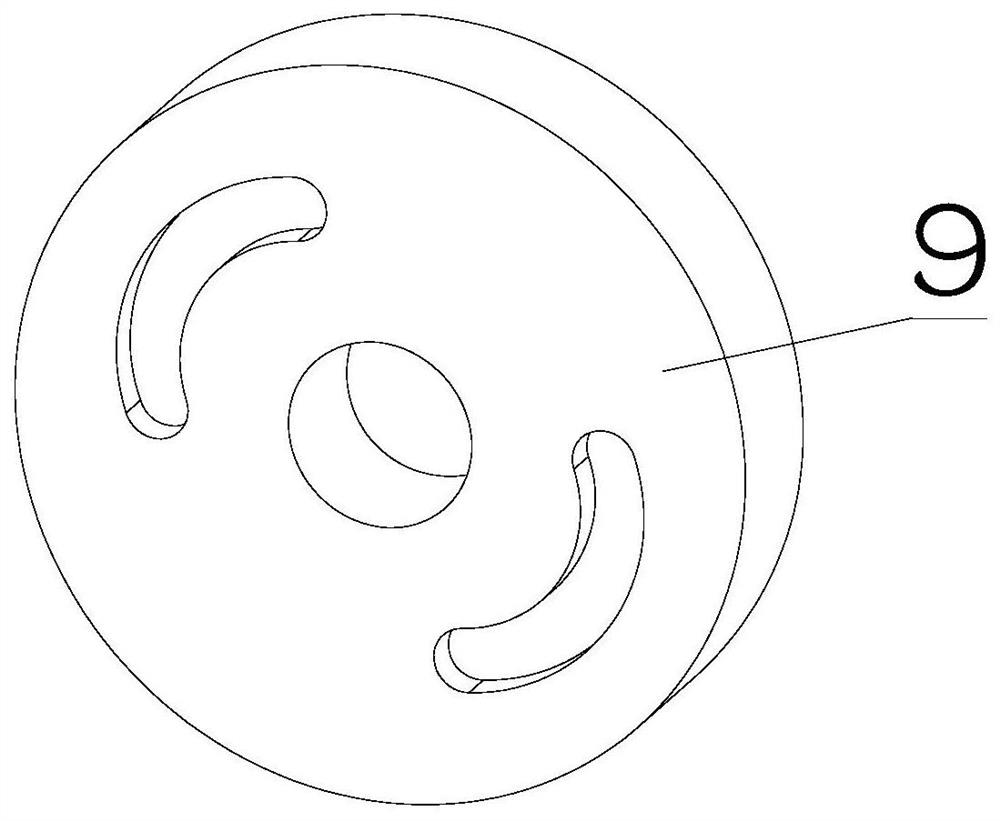

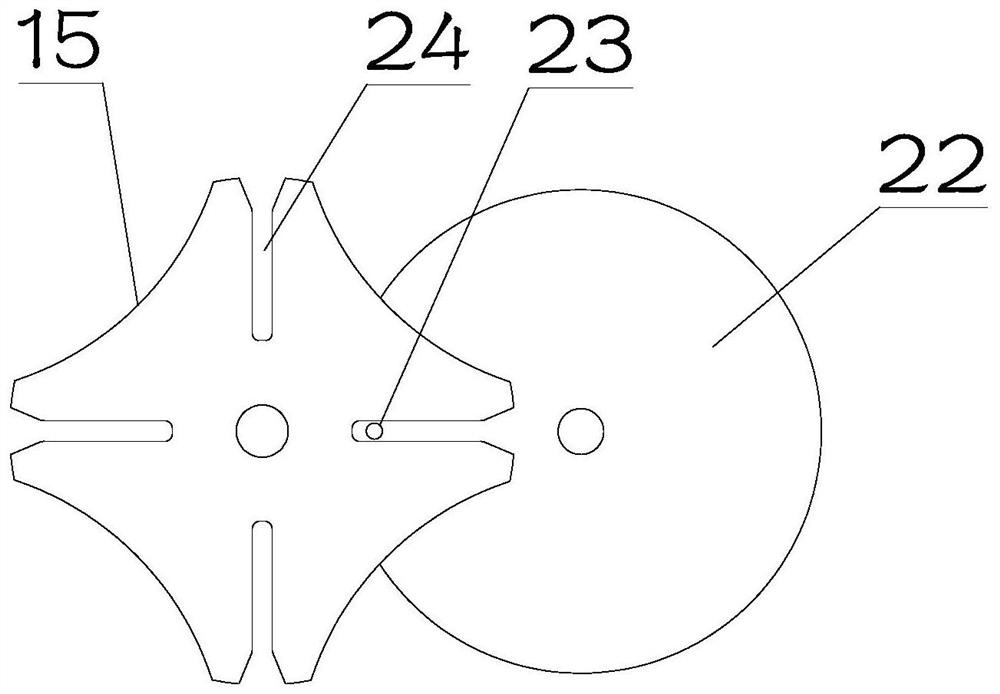

[0023] see Figure 1~3 , in Embodiment 1 of the present invention, a structure diagram of a dust removal device for building construction provided by the embodiment of the present invention, including: a device main body 1, the interior is divided into a dust removal chamber and a cleaning chamber by a partition; the interior of the device main body 1 Intermittent rotation is provided with a rotating disc 3, the bottom of the rotating disc 3 is provided with a plurality of filter cylinders 2 in an array, and the lower ends of the plurality of filter cylinders 2 are fixedly sleeved on the outside of the supporting shaft 26, and the upper end of the supporting shaft 26 is rotatably mounted on the rotating shaft. On the disc 3, a plurality of through holes 4 are arranged in an array on the rotating disc 3, and the plurality of through holes 4 are arranged one by one at the outlet above the plurality of filter screen cylinders 2; the inside of the dust removal chamber is also provi...

Embodiment 2

[0026] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that in order to be able to clean the filter screen cylinder 2 inside the cleaning chamber, a brush 11 is provided for self-rotation inside the cleaning chamber, and the brush 11 is attached to the cleaning chamber. On the surface of one of the filter screen cylinders 2 inside, a driving assembly is provided inside the cleaning chamber for driving the filter screen cylinder 2 to rotate.

[0027] Specifically, the drive assembly includes a self-rotating driving disk 6, which is frictionally set with the transmission disk 5 at the bottom of the supporting shaft 26, and the driving disk 6 and the transmission disk 5 are both rubber wheels, so that the supporting shaft When the drive disc 5 on the 26 was close to the drive disc 6, the drive disc 6 could drive the drive disc 5 to drive the supporting rotating shaft 26 to rotate, so as to provide power for the drive disc 5 to rotate.

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com