Turntable filter

A technology of a turntable filter and a filter, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of complex structure of water filtering device, incomplete filtration, high use cost, etc., and achieve design cycle and construction cycle Short, backwash water volume is small, the effect of low equipment idle rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

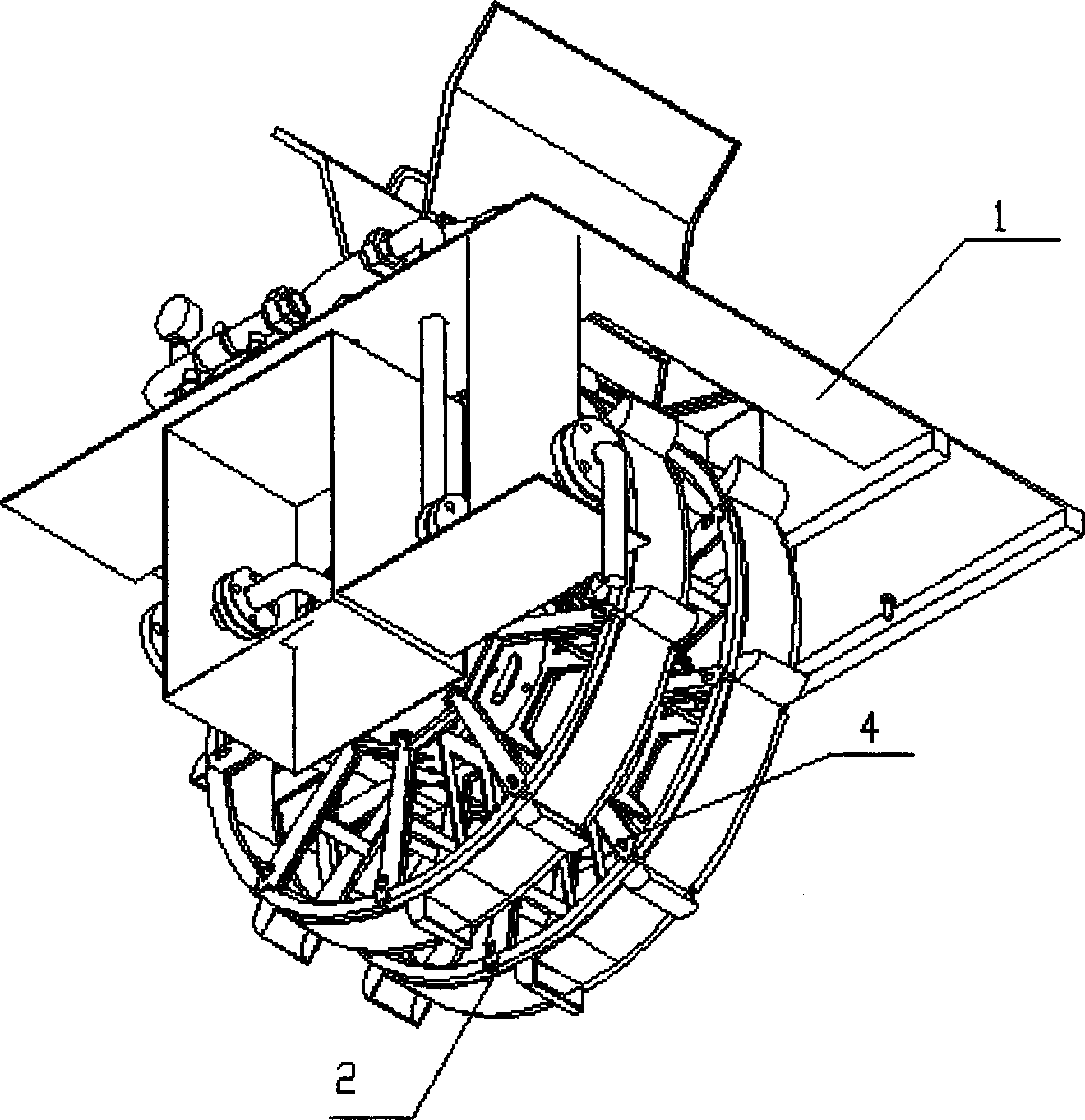

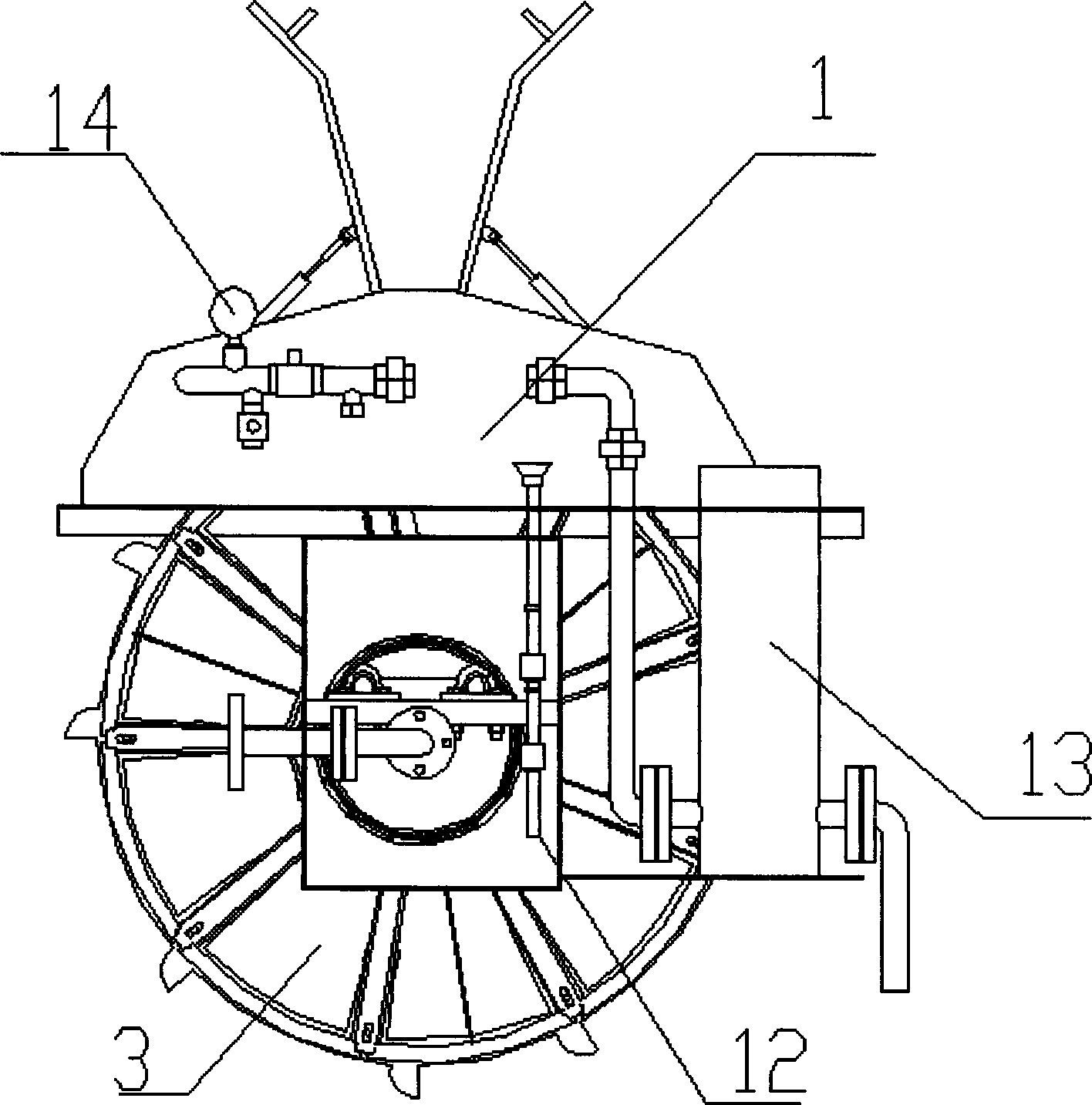

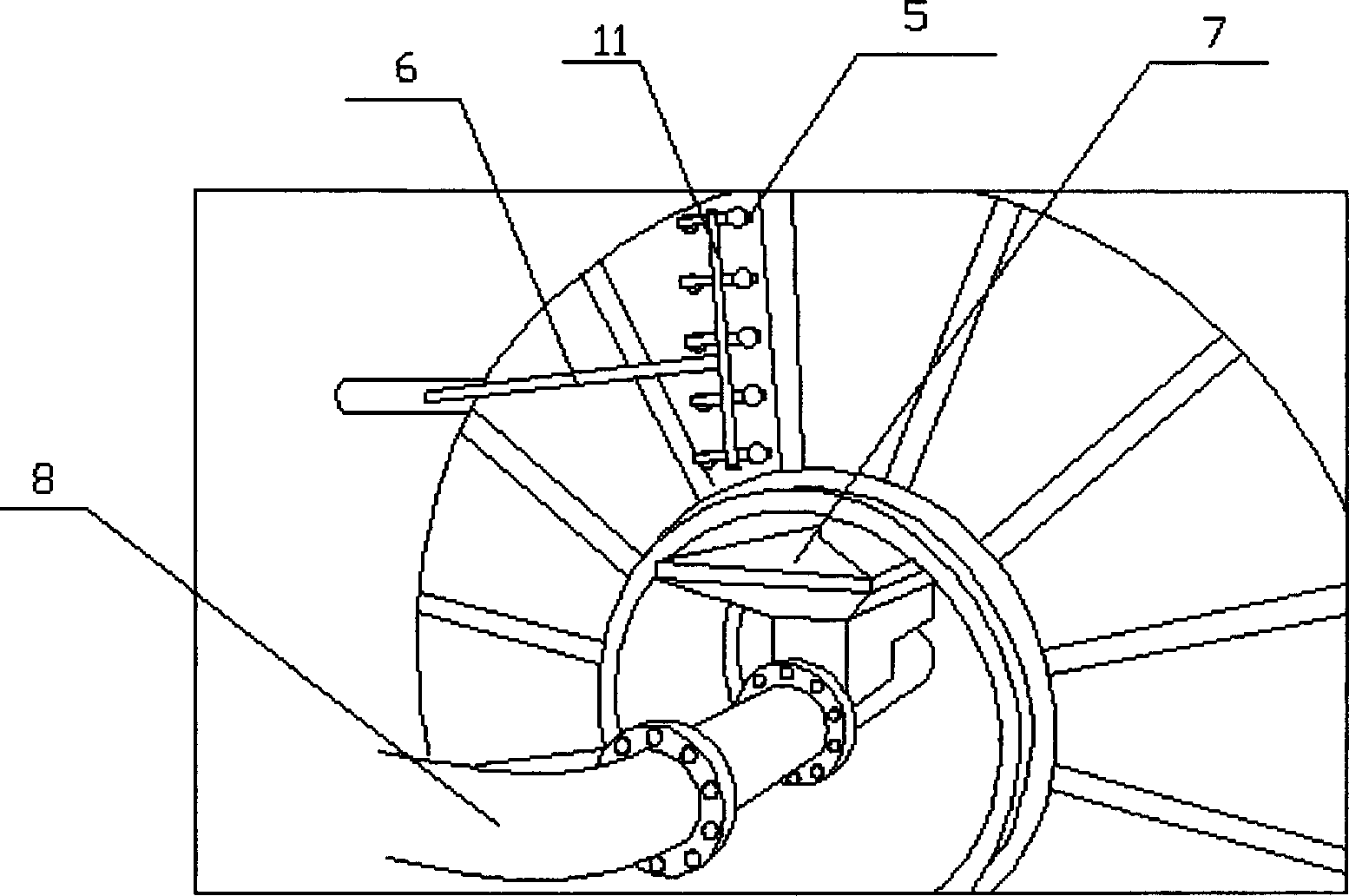

[0038] like figure 1 , figure 2 image 3 , Figure 4 and Figure 5 As shown, a turntable filter of the present invention comprises a main body frame, a core filter system filter screen, a drive system, a backwash system, and an automatic control system. The main frame is composed of a shell 1, a central water inlet pipe, a drum 2, Linkage gears, rotating bearings, central drums and seals. The filter screen of the core filter system is composed of independent filter mesh sheets 3, drum frame 4 and filter pool. The drive system includes drive motors, drive gears, and drum support wheels. , the backwashing system includes a backwashing water pump, a backwashing nozzle 5, a flushing water pipe 6, a nozzle system, a dirt collection tank 7 and a sewage pipe 8, and the filter mesh 3 is installed on both sides of the drum 2, and the backwashing The system is respectively arranged outside the filter mesh 3 on both sides of the drum 2, the sewage discharge pipe 8 and the central wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com