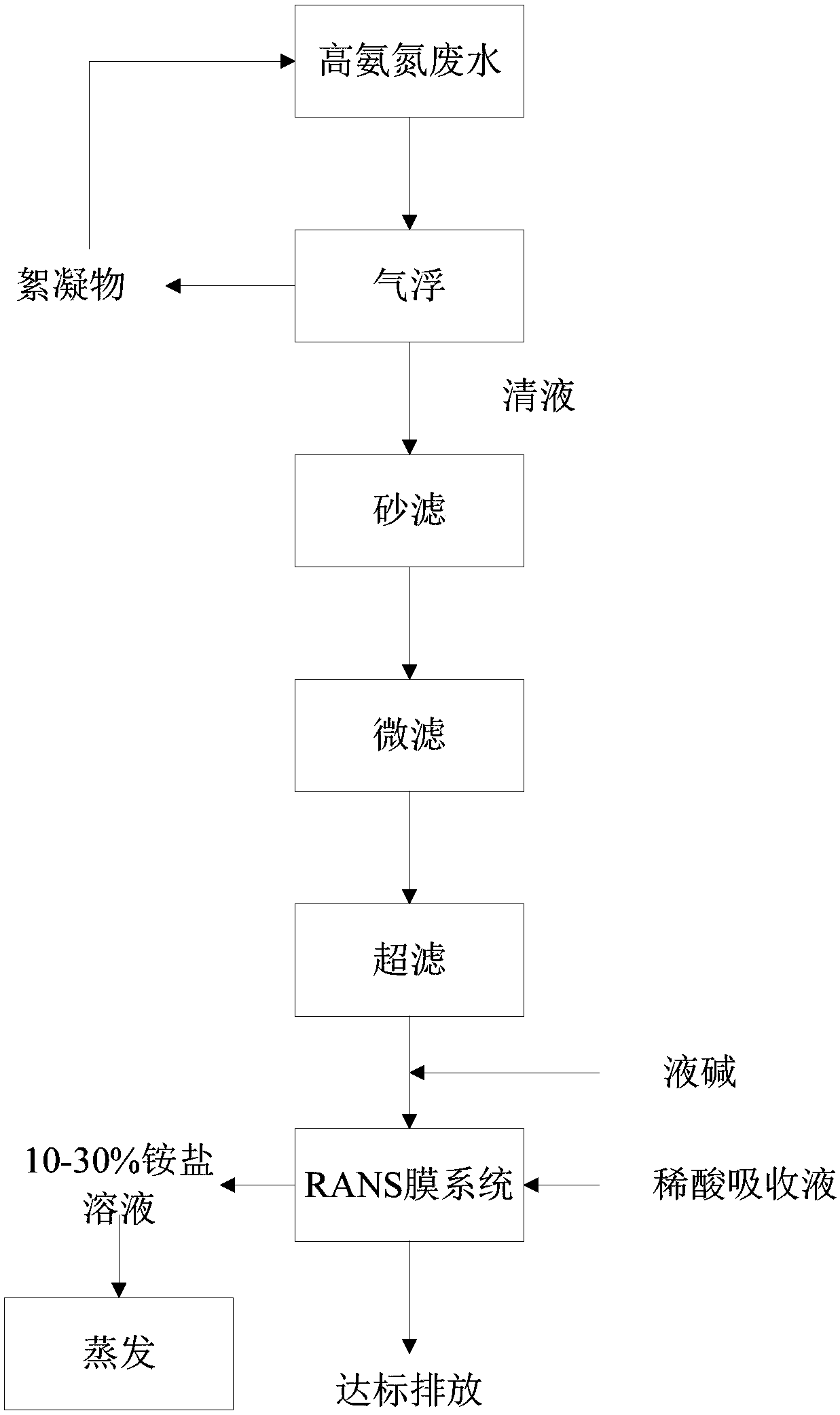

High ammonia-nitrogen wastewater treatment method

A treatment method, high ammonia nitrogen technology, applied in water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of large floor area, high operating costs, and large investment costs. Achieve the effects of small footprint, low power consumption, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The water quality information of a printing and dyeing wastewater is COD: 1859ppm, ammonia nitrogen value: 1050ppm, total nitrogen value: 1050ppm, pH is 8.9, and conductivity is 7.2ms / cm.

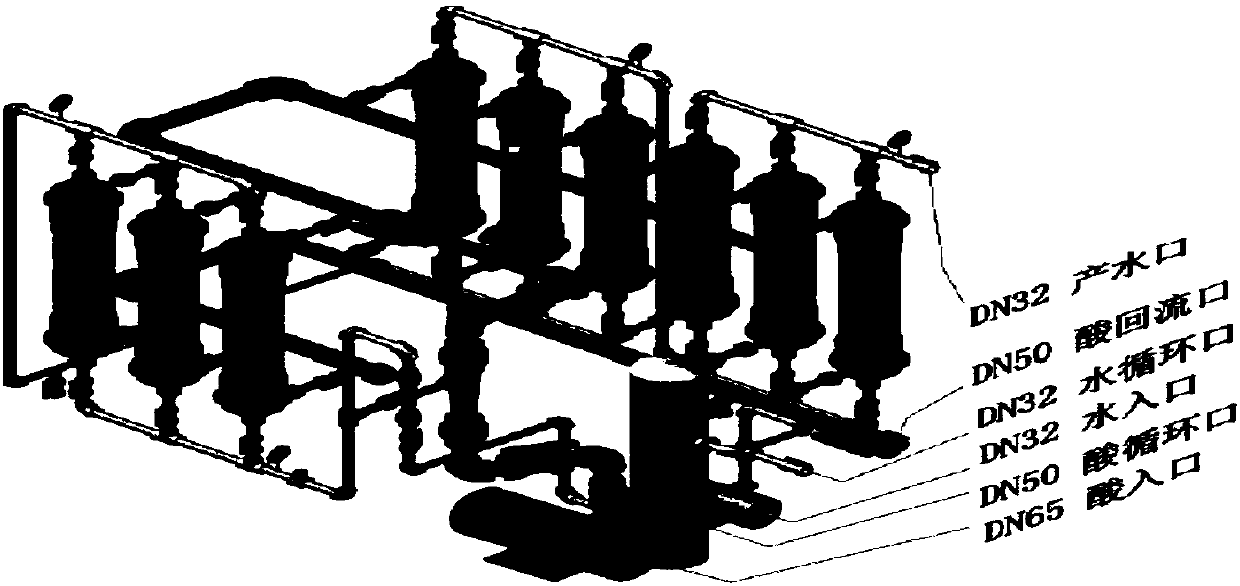

[0034] The wastewater is initially mixed with polymerized alumina, and then pre-reacted with polyacrylamide, so that the suspended matter in the wastewater forms a larger floc, and then it is evenly mixed with the dissolved air water in the air flotation device to form a larger floc. In the separation zone of the air flotation device, the air flocs are separated from the clear filtrate. The clear filtrate flows downstream from the outlet pipe of the air flotation device to the sand filter device. The dosages of polyaluminum chloride (PAC) and polyacrylamide (PAM) were 12.5 mg / L and 2.5 mg / L respectively, and the reflux ratio was 10.5%. After the wastewater is filtered by sand filter, bag filter and ultrafiltration membrane system, various suspended solids, microorganisms and other f...

Embodiment 2

[0039] The water quality information of a printing and dyeing wastewater is COD: 1859ppm, ammonia nitrogen value: 1050ppm, total nitrogen value: 1050ppm, pH is 8.9, and conductivity is 7.2ms / cm.

[0040]The wastewater is initially mixed with polyferric chloride, and then pre-reacted with polyacrylamide, so that the suspended solids in the wastewater form larger flocs, and then evenly mixed with the dissolved air water in the air flotation device to form larger flocs , In the separation zone of the air flotation device, the air flocs are separated from the clear filtrate. The clear filtrate flows downstream from the outlet pipe of the air flotation device to the sand filter device. The dosages of PAC and PAM were 12.5mg / L and 2.5mg / L respectively, and the reflux ratio was 10.5%. After the wastewater is filtered by sand filter, bag filter and ultrafiltration membrane system, various suspended solids, microorganisms and other fine particles in the wastewater are removed. Use li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com